Hydrolysis resisting polyester resin composition and preparation method

A polyester resin and composition technology, applied in the field of thermoplastic polyester resin compositions, can solve the problems of exudation of small molecular compounds, increase in melt viscosity, poor thermal stability, etc., achieve excellent thermal stability, and improve hydrolysis resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

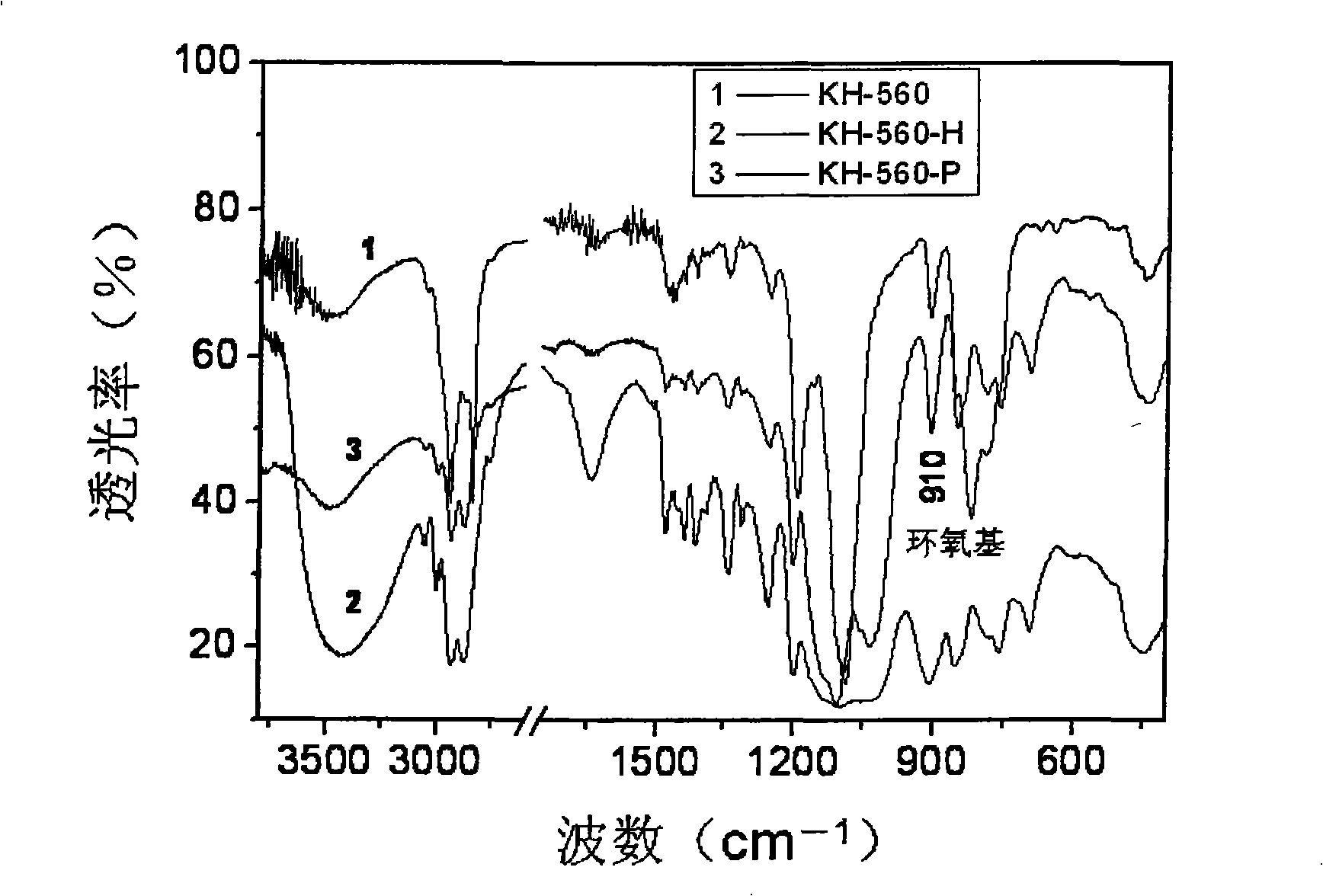

[0030] Preparation of Silica Particles Containing Epoxy Functional Groups

[0031]Mix 118.0g (0.5mol) of γ-(2,3-glycidyloxy)propyltrimethoxysilane (KH-560), with 27.0g (1.5mol) of deionized water, 69.0g (1.5mol) of anhydrous Ethanol was mixed, and electromagnetically stirred at room temperature for 4 hours to hydrolyze the siloxane, and then the temperature of the system was raised to 60°C and stirred for 4 hours to obtain a viscous liquid (KH-560-H). The viscous liquid was condensed in a vacuum oven at 80°C, 100°C, 120°C, and 150°C for 2 hours respectively, and finally condensed at 200°C for 1 hour to obtain a white solid. The obtained solid was pulverized by a high-speed pulverizer to obtain silica particles (KH-560-P) containing epoxy functional groups. Infrared spectrum shows that the obtained silica particles contain significant epoxy functional group absorption peaks ( figure 1 ). Thermogravimetric analysis (TGA) shows that the heat-resistant temperature of the sample...

Embodiment 1-3

[0035] After drying polyethylene terephthalate (F20S, Japan Toray Co.) in vacuum at 150°C for 6 hours, after mixing with KH-560-P obtained at a final condensation temperature of 200°C, pass it through a twin-screw extruder Extrusion yields blended chips. The temperature of the feeding section of the extruder is 230°C, the temperature of the remaining sections is 260°C, and the screw speed is 200 rpm. The intrinsic viscosity and molecular weight changes before and after the hydrolysis test of the obtained resin were analyzed, and the results are shown in Table 1.

[0036] Table 1

[0037]

Embodiment 4

[0039] PET (F20S, Japan Toray Co., Ltd.) was vacuum-dried at 150°C for 6 hours, mixed with KH-550-P obtained at a final condensation temperature of 200°C, and extruded through a twin-screw extruder (manufactured by Technovel) to obtain Blend slices. The temperature of the feeding section of the extruder is 230°C, the temperature of the remaining sections is 260°C, the screw speed is 200 rpm, and the resin stays in the extruder for 5 minutes on average. Analyze the intrinsic viscosity and molecular weight changes of the obtained resin before and after the hydrolysis test, and the results are shown in Table 2.

[0040] Table 2

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com