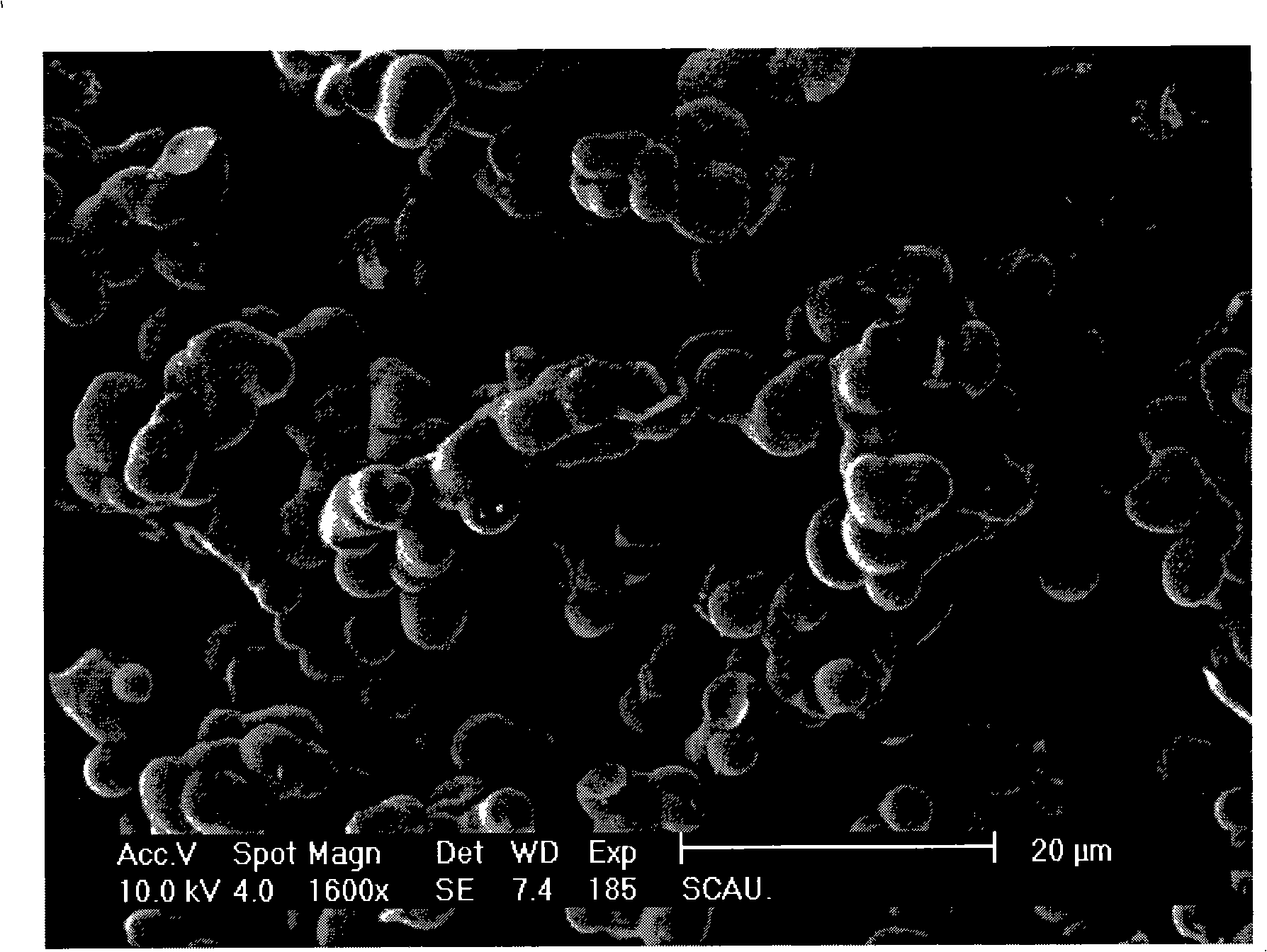

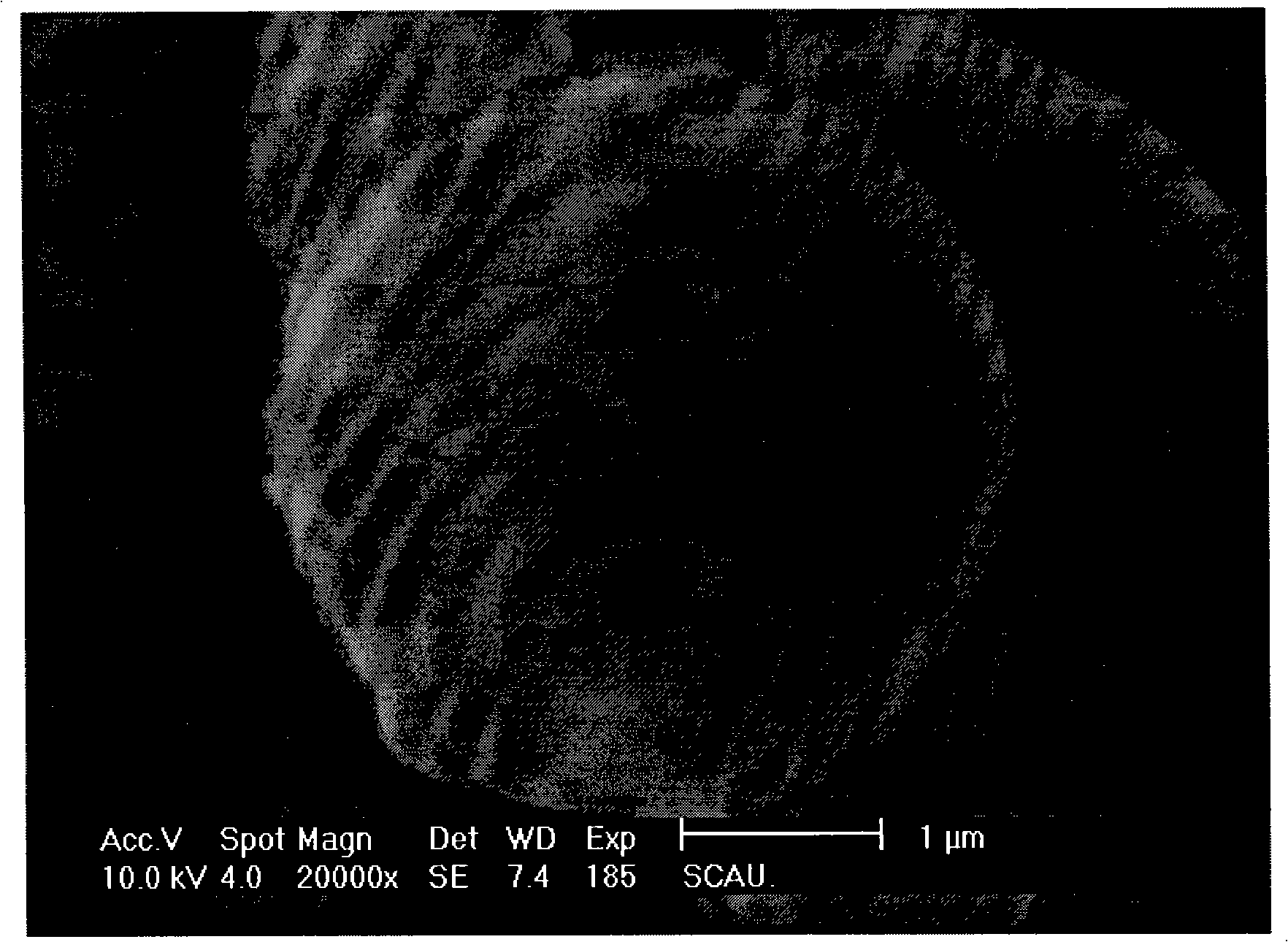

Biological activity glass mesoporous microsphere and preparation method thereof

A bioactive glass and mesoporous technology, applied in the field of biomedical microsphere materials, can solve the problems of difficult control of degradation rate, acidity of degradation products, sudden drug release, etc., achieving small particle size, good dispersibility, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2N hydrochloric acid into deionized water, stir and mix evenly, adjust the pH value to 1, add ethyl orthosilicate (TEOS), triethyl phosphate (TEP) and calcium nitrate tetrahydrate in sequence for hydrolysis reaction, and finally add organic template Polyethylene glycol was added, and a transparent, uniform and stable sol was obtained after fully stirring. Among them, the molar ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 60:4:36, the molar ratio of deionized water to ethyl orthosilicate is 10:1, polyethylene glycol and orthosilicate The molar ratio of ethyl silicate is 0.002;

[0024] (2) Static aging of the sol obtained in step (1) for 4 days to form a wet gel;

[0025] (3) Soak and wash the gel with absolute ethanol 6 times for 10 minutes, and the volume ratio of absolute ethanol to wet gel is 10:1;

[0026] (4) Drying the wet gel obtained in step (3) in an oven at 60°C for 3 days, and then drying in an oven at 120°C for ...

Embodiment 2

[0030] Add 2N nitric acid into deionized water, stir and mix evenly, adjust the pH value to 3, add ethyl orthosilicate (TEOS), triethyl phosphate (TEP) and calcium nitrate tetrahydrate in sequence for hydrolysis reaction, and finally add organic template Polyethylene glycol was added, and a transparent, uniform and stable sol was obtained after fully stirring. Among them, the molar ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 80:4:16, the molar ratio of deionized water to ethyl orthosilicate is 8:1, polyethylene glycol and orthosilicate The molar ratio of ethyl silicate is 0.004;

[0031] (2) Static aging of the sol obtained in step (1) for 4 days to form a wet gel;

[0032] (3) Soak and wash the gel with absolute ethanol 6 times for 10 minutes, and the volume ratio of absolute ethanol to wet gel is 10:1;

[0033] (4) Drying the wet gel obtained in step (3) in an oven at 60°C for 3 days, and then drying in an oven at 120°C for 3 days ...

Embodiment 3

[0037] Add 10% ammonia water into deionized water, stir and mix evenly, adjust the pH value to 13, add ethyl orthosilicate (TEOS), triethyl phosphate (TEP) and calcium nitrate tetrahydrate in sequence for hydrolysis reaction, and finally add organic The template agent is polyethylene glycol, and a transparent, uniform and stable sol can be obtained after fully stirring. Among them, the molar ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 60:4:36, the molar ratio of deionized water to ethyl orthosilicate is 12:1, polyethylene glycol and orthosilicate The molar ratio of ethyl silicate is 0.007;

[0038] (2) aging the sol obtained in step (1) statically for 6 days to form a wet gel;

[0039] (3) Soak and wash the gel with absolute ethanol 6 times for 20 minutes, and the volume ratio of absolute ethanol to wet gel is 8:1;

[0040] (4) drying the wet gel obtained in step (3) in an oven at 80°C for 3 days, and then drying in an oven at 100°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com