Method for producing methyl hydride and electricity with solar energy

A solar energy and solar greenhouse technology, applied in the energy field, can solve the problems of complex solar energy plant conversion and plant utilization system, consume a lot of energy, consume a large amount of energy, etc., and achieve the effects of increasing plant growth rate, increasing plant yield, and increasing carbon dioxide concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

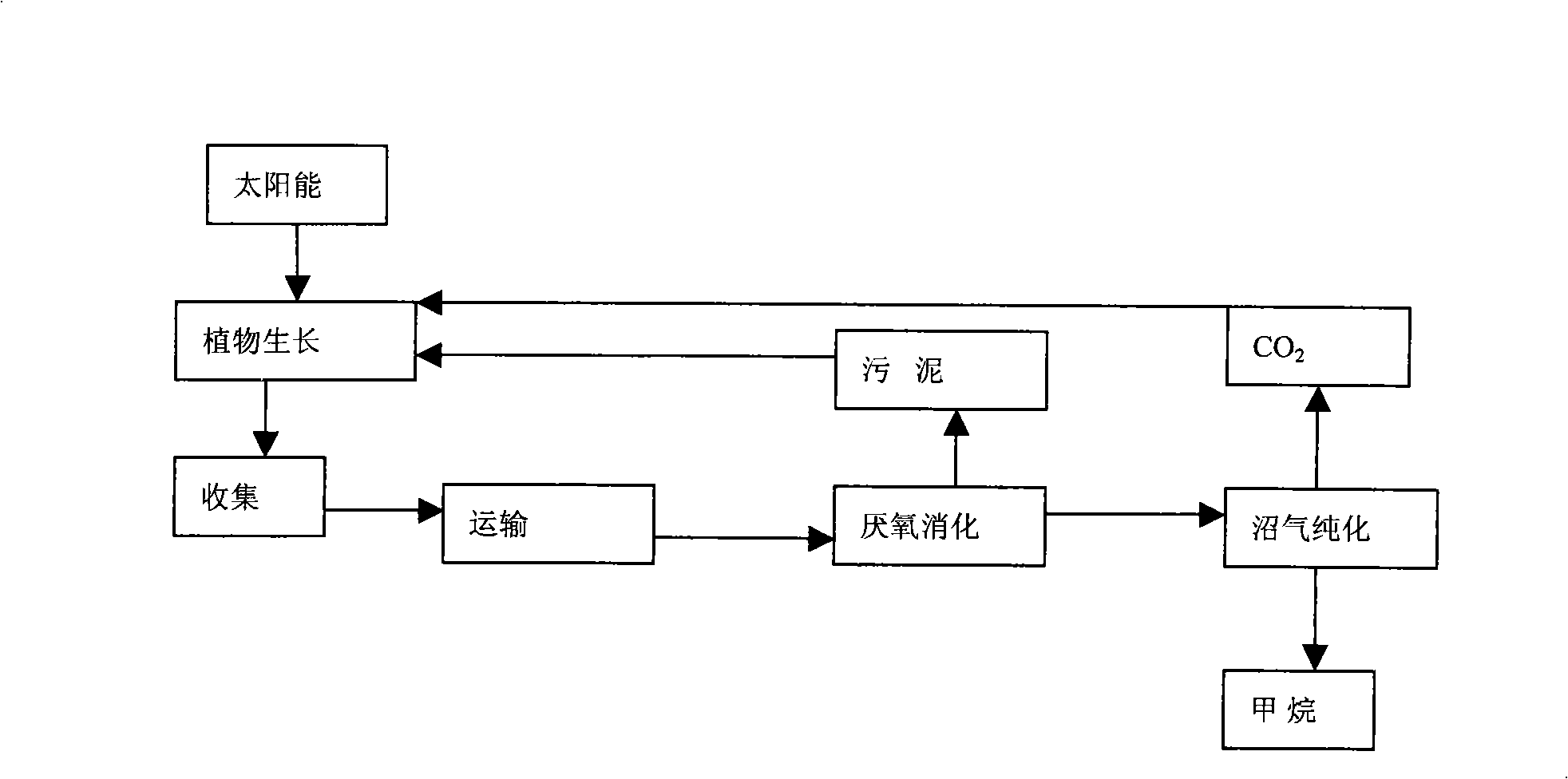

[0034] Tall fescue is planted in a greenhouse with an area of 300 mu, and 0.5-1.5 tons of tall fescue stems and leaves are collected every day, equivalent to hay. 3 Fermentation in anaerobic digestion reactor 2 to generate biogas 300-900m 3 , biogas residue and biogas slurry are artificially sprinkled into the greenhouse 1 to be used as fertilizer for the growth of tall fescue, and the methane and carbon dioxide in the biogas are separated in the separator 3, and the carbon dioxide is passed into the greenhouse to increase the concentration of carbon dioxide in the greenhouse and promote plant photosynthesis and Output, methane becomes product output after desulfurization and drying, and produces 180-540m methane per day3 about.

Embodiment 2

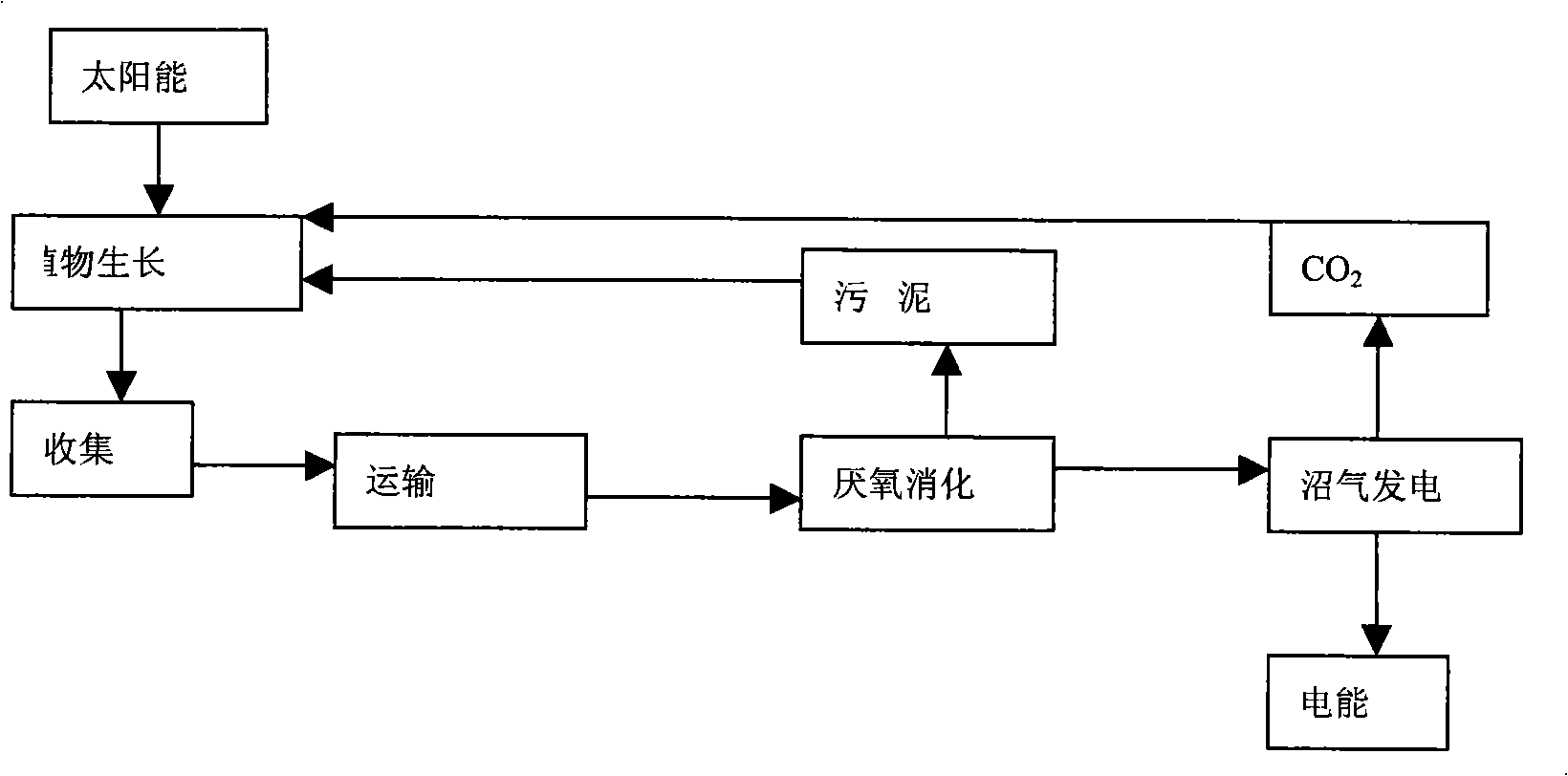

[0036] Plant alfalfa on an area of 1,500 mu of land, and collect 2.5-7.5 tons of alfalfa stems and leaves equivalent to hay every day. 3 Fermentation in anaerobic digestion reactor 2 to generate biogas 1500-4000m 3 , biogas residue and biogas slurry are used as fertilizers for plant growth, and the biogas is directly burned with the air in the greenhouse to generate electricity of about 3000-8000kwh in the gas turbine 4 .

Embodiment 3

[0038] In a greenhouse with an area of about 150 mu, a pool with a depth of 1m is set up to plant hyphae hyphae. The pool is composed of two closed circular channels formed between three circular walls with diameters of 350 meters, 120 meters and 10 meters. The depth of the local area in the channel is 3 meters, and a low-speed thruster with a diameter of 1.8 meters is installed to push the water body to flow at a flow speed of 0.01-0.05m / s. The sewage with a flow rate of 10,000 tons / day removes larger solids through the grille, removes solids with a larger specific gravity through the grit chamber, and flows into the sedimentation tank composed of a 10-meter circular wall. The settled sludge and solids removed by the grille are sent to It enters the anaerobic digestion reactor, and the effluent enters the annular pool. The ring-shaped pool ditch is equipped with hydrangea collection equipment, which is composed of a belt conveyor, a crushing device and a pump. The stems and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com