Method for producing nano-silver powder or nano-gold powder

A technology of nano-silver powder and silver salt, which is applied in the field of preparation of nano-silver powder or nano-gold powder by electrochemical sacrificial anode method, which can solve the problems of difficult operation and high cost of nano-silver, and achieve the effect of high purity, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: a kind of method for preparing nano-silver powder

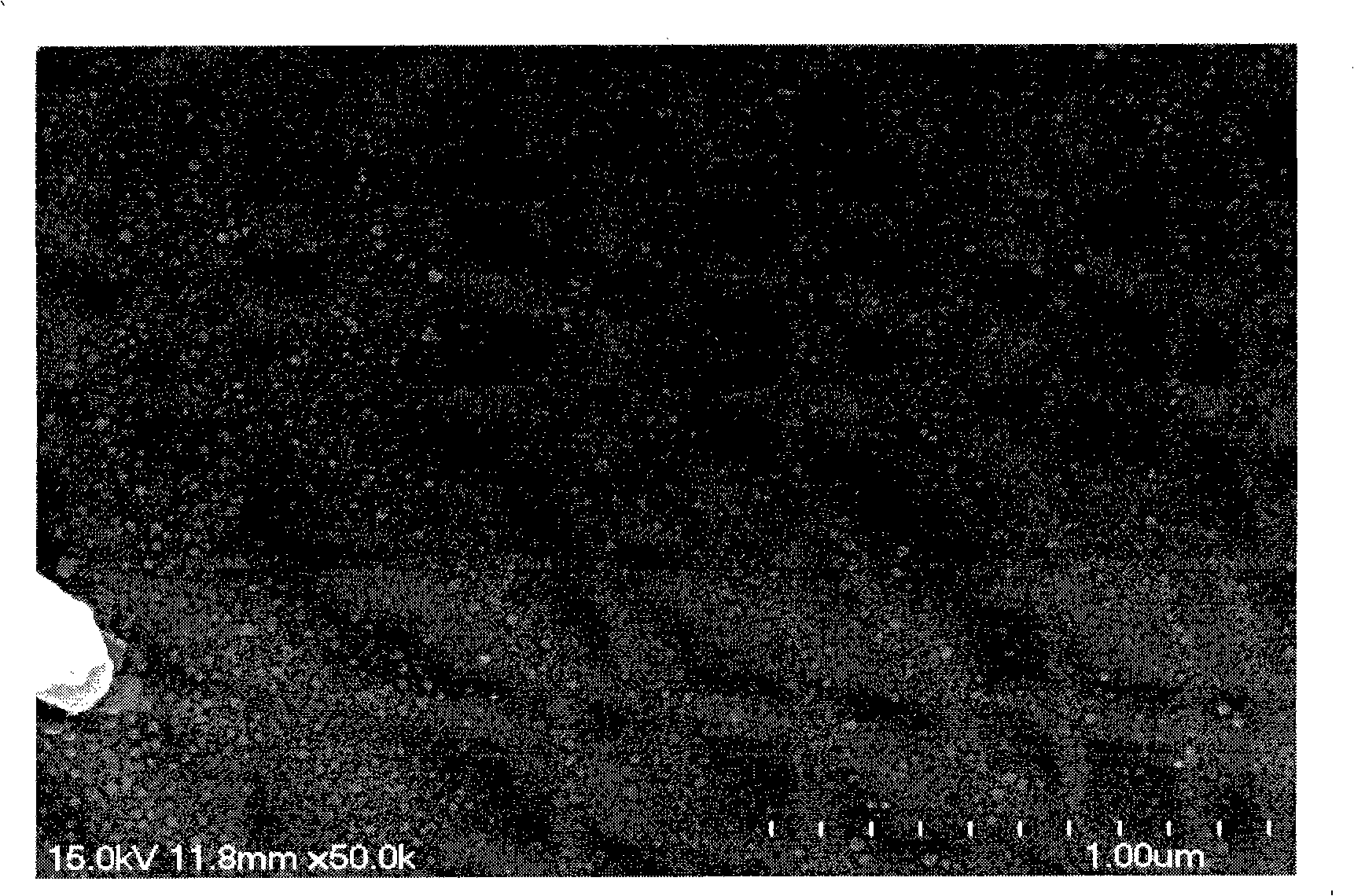

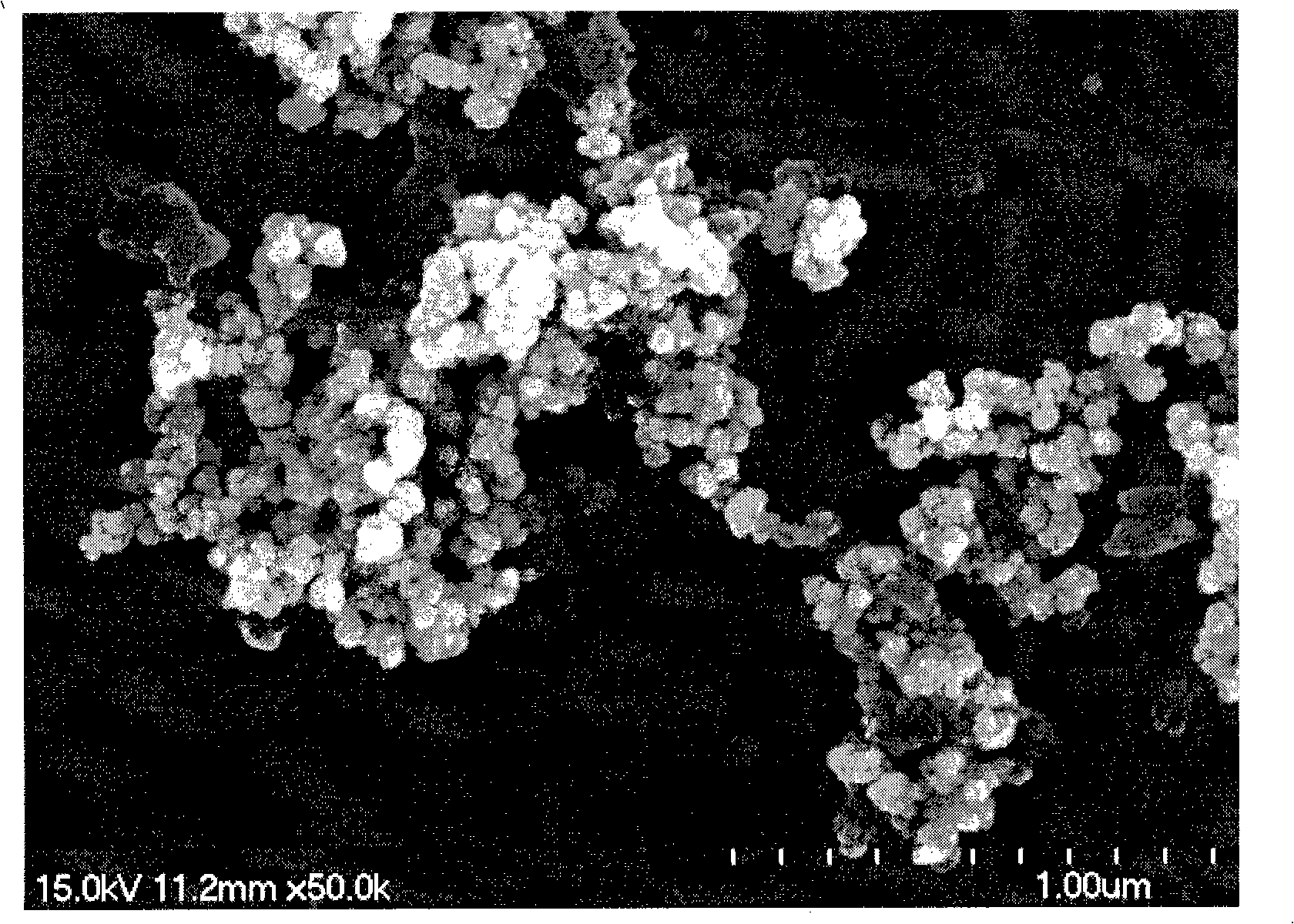

[0034] In a 25ml single-chamber electrolytic cell, add 0.065g of silver tetrafluoroborate (AgBF 4 ) and 5.0ml ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate ([bmim]BF 4), the silver salt is fully dissolved at 80°C, and the filtrate is obtained after filtration; the metal silver (12mm×40mm, purity is 99.9%) is used as the anode, the platinum wire is the cathode, and the filtrate is the electrolyte. 100W), the cell voltage is 2.0V, and the current density is 0.5A / dm 2 , the pole distance is 5mm, the electrolysis temperature is 20-40°C, there is soot-like powder precipitated near the cathode, stop the electrolysis after 2 hours, filter the electrolyte suspension, and wash the soot-like powder with absolute ethanol (5.0ml each time) for 5-5~ 8 times, dry naturally to get nano-silver powder. After electron microscope scanning, the morphology of the obtained product is as follows: figure 1 sho...

Embodiment 2

[0035] Embodiment two: a kind of method for preparing nano-silver powder

[0036] In a 25ml single-chamber electrolytic cell, add 0.15g of silver tetrafluoroborate (AgBF 4 ) and 5.0ml ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate ([bmim]PF 6 ), the silver salt is fully dissolved at 80°C, and the filtrate is obtained after filtration; the metal silver (12mm×40mm, purity is 99.9%) is used as the anode, the tungsten wire is the cathode, and the filtrate is the electrolyte. 100W), the cell voltage is 2.0V, and the current density is 0.27A / dm 2 , the pole distance is 15mm, the electrolysis temperature is 20-50°C, soot-like powder is precipitated near the cathode, stop the electrolysis after 3 hours, filter, wash the soot-like powder with acetone (5.0ml each time) for 5-8 times, and dry naturally. Get nano silver powder.

Embodiment 3

[0037] Embodiment three: a kind of method for preparing nano-silver powder

[0038] In a 25ml single-chamber electrolytic cell, add 0.56g of silver tetrafluoroborate (AgBF 4 ) and 5.0ml ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate ([emim]BF 4 ), the silver salt is fully dissolved at 80°C, and the filtrate is obtained after filtration; the anode is the metal silver (12mm × 40mm, purity 99.9%), the silver sheet is the cathode, and the filtrate is the electrolyte, which is electrolyzed by direct current, ultrasonic (ultrasonic power 100W), the cell voltage is 1.5V, and the current density is 11.0A / dm 2 , the pole distance is 45mm, the electrolysis temperature is 20-28°C, soot-like powder is precipitated near the cathode, stop the electrolysis after 0.5h, filter, wash the soot-like powder with absolute ethanol (5.0ml each time) for 5-8 times, and naturally Dry to get nanometer silver powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com