Method for preparing fibre

A manufacturing method and fiber technology, which is applied in the field of fiber manufacturing, can solve the problems of inconspicuous and short-term effects of fibers, and achieve the effects of no toxic side effects, long-lasting effects, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

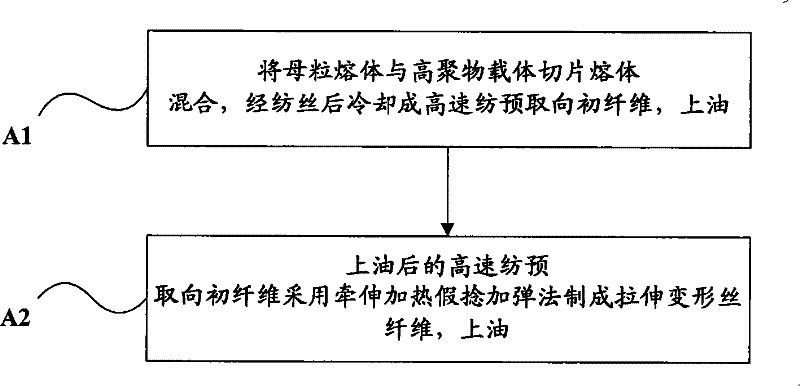

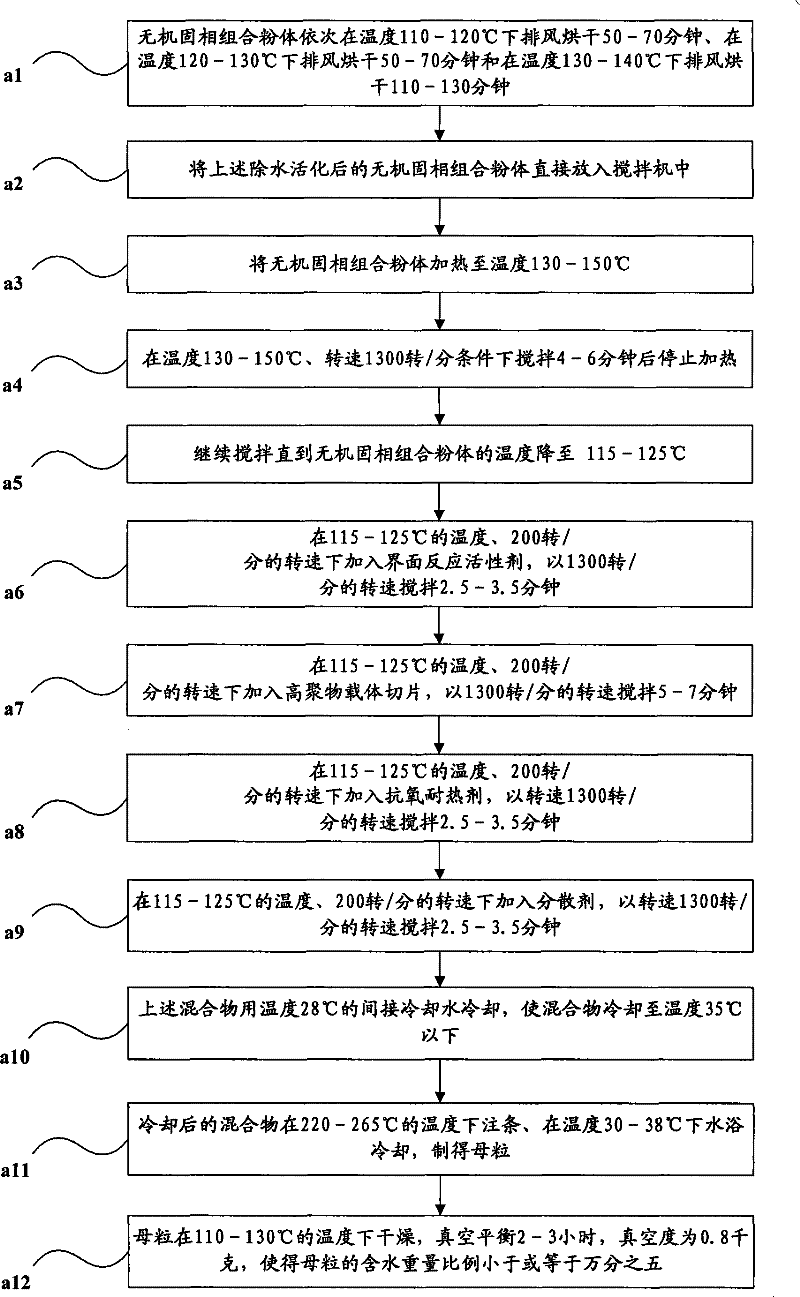

Method used

Image

Examples

no. 1 example

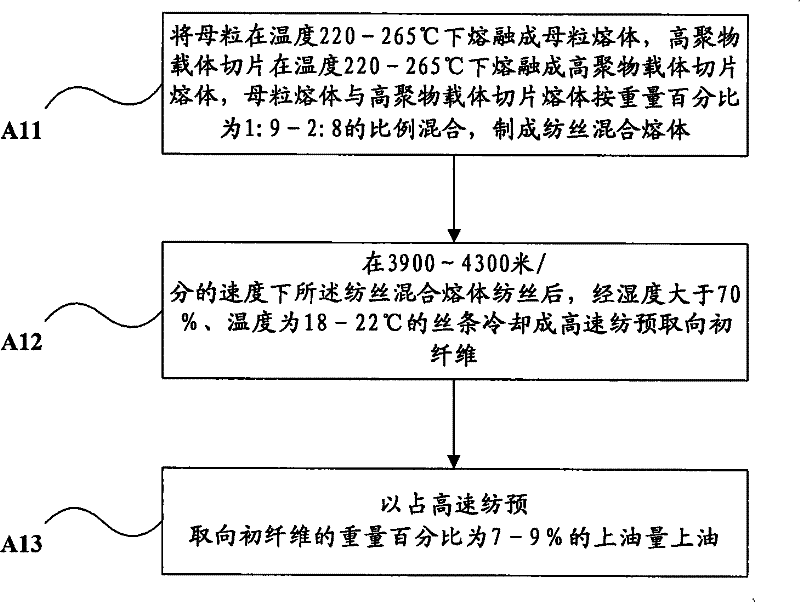

[0048] Step A101, adding the masterbatch into a small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 240°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 240°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 1:9 by weight to make a spinning mixed melt, and the spinning mixed melt in the twin-screw extruder passes through the insulation pipe from Zone 2 of the extruder enters the spinning extruder;

[0049] Step A102, after spinning mixed melt spinning at a speed of 4300 m / min, cooling the filaments with a humidity of 75% and a temperature of 20°C to form high-speed spinning pre-oriented primary fibers;

[0050] Step A103, oiling with an oiling amount of 8% of the weight percentage of the high-speed spinning pre-oriented primary fibers;

[0051] Step A104, drafting the high-speed spinning pre-oriented primary fiber after oiling, the drafting ratio...

no. 2 example

[0053] Step A201, adding the masterbatch into the small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 220°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 220°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 1.5:8.5 by weight to make a spinning mixed melt. Zone 3 of the extruder enters the spinning extruder;

[0054] Step A202, after spinning mixed melt spinning at a speed of 3900 m / min, cooling the strands with a humidity of 71% and a temperature of 18°C to form high-speed spinning pre-oriented primary fibers;

[0055] Step A203, oiling with an oiling amount of 7% of the weight percent of the high-speed spinning pre-oriented initial fibers;

[0056] Step A204, drafting the high-speed spinning pre-oriented primary fiber after oiling, the drafting ratio is 1.5 times, and adopting the heating false twisting method to make stretched textured sil...

no. 3 example

[0058] Step A301, adding the masterbatch into the small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 265°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 265°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 2:8 by weight to make a spinning mixed melt, and the spinning mixed melt in the twin-screw extruder passes through the insulation pipe from the spinning Zone 2 of the extruder enters the spinning extruder;

[0059] Step A302, after spinning mixed melt spinning at a speed of 4100 m / min, cooling the sliver with a humidity of 80% and a temperature of 22°C to form high-speed spinning pre-oriented primary fibers;

[0060] Step A303, oiling with an oiling amount of 9% of the weight percentage of the high-speed spinning pre-oriented primary fibers;

[0061] Step A304, drafting the high-speed spinning pre-oriented primary fiber after oiling, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com