Method and device for forming PN junction on P type mercury cadmium telluride by laser process

A laser processing and mercury cadmium telluride technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the probability of blind cells in photosensitive element arrays and the negative impact on device yield, so as to reduce the blind cell rate , The effect of simple knot formation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

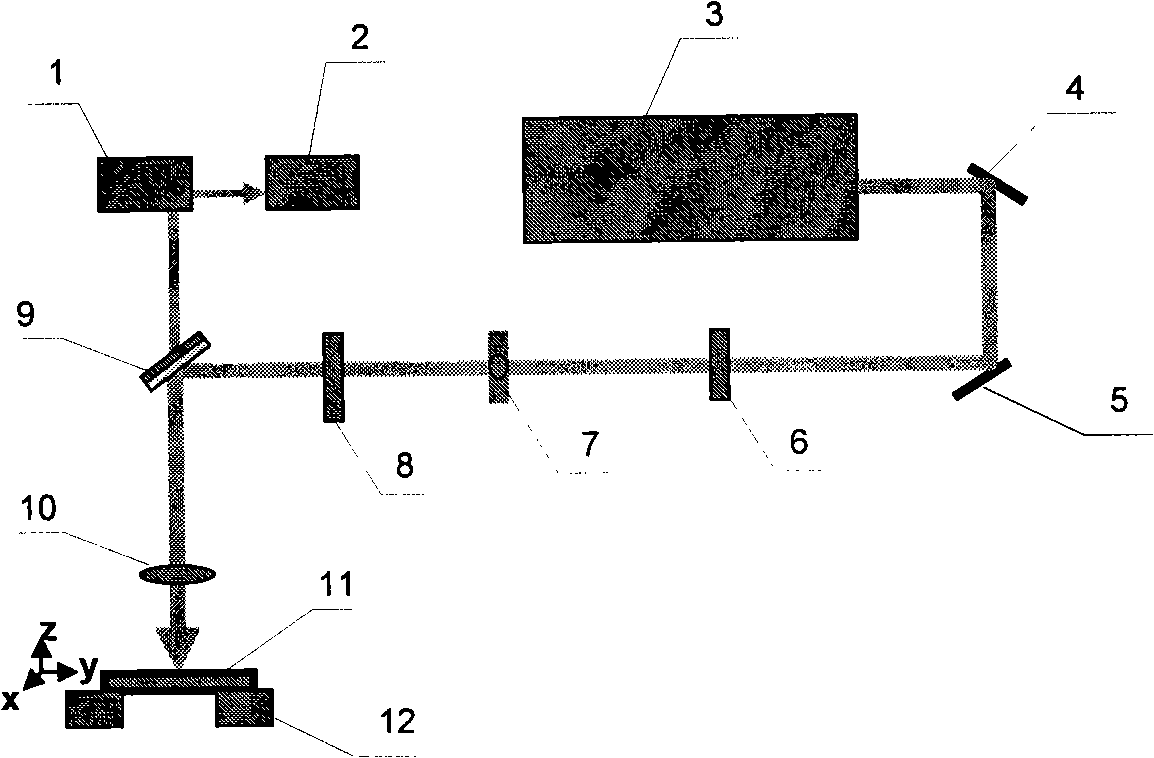

[0018] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

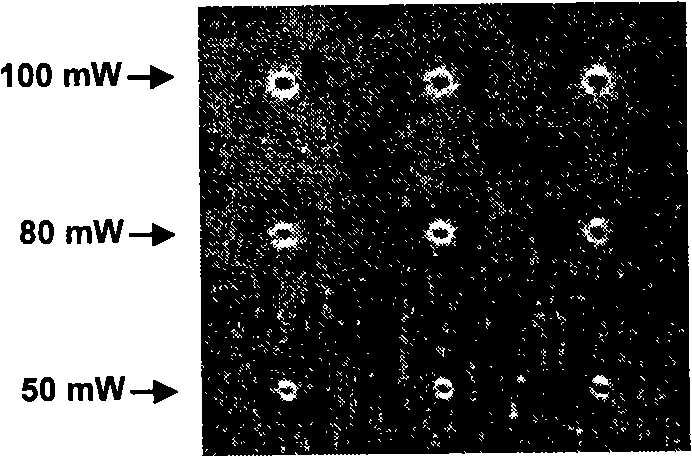

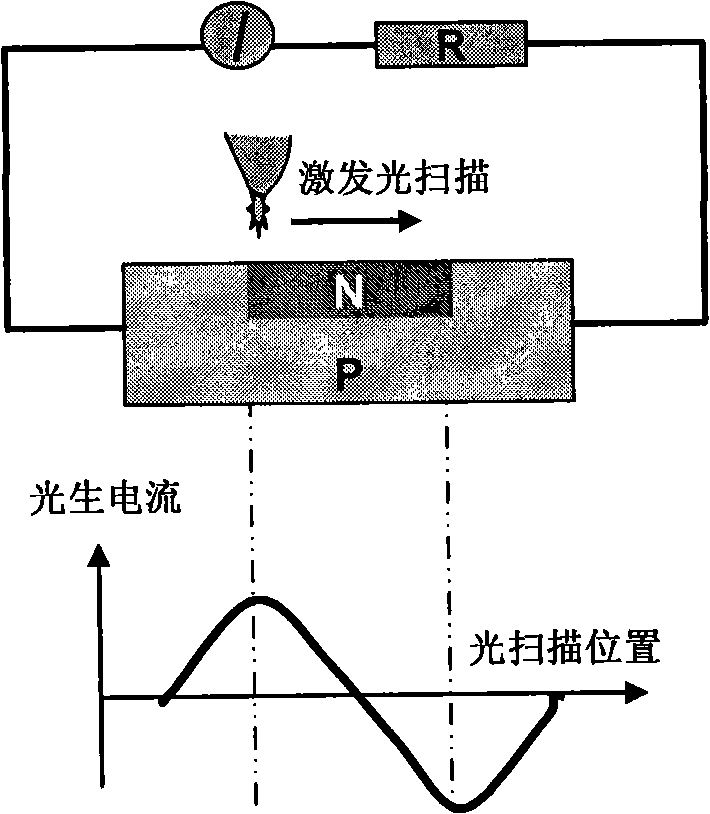

[0019] The method of laser processing in this example to form a PN junction on the P-type HgCdTe material is: focus the pulse laser on the surface of the P-type HgCdTe material, and irradiate the P-type HgCdTe material in a short period of time. In this way, a hole area ablated by the laser is formed on the material, and the diameter of the hole is several microns to more than ten microns; an inversion area, that is, an N-type area, is formed in the area of several microns around the hole, and the inversion area and the P area around the hole are formed. Type region forms a PN junction region.

[0020] The experimental sample in this example is a HgCdTe film material grown on a CdZnTe substrate by liquid phase epitaxy. The thickness of the epitaxial film is 24 μm, and the surface is covered with a 0.25 μm ZnS passivation layer. Hall test gives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com