A kind of preparation method of phase-change memory array

A phase-change memory and phase-change storage technology, which is applied in the field of micro-nano electronics, can solve the problems of lengthy process, complex process, and increasing the number of three-dimensional stacking layers, and achieve the goals of improving the preparation process, simplifying the preparation process, and saving photolithography stripping steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

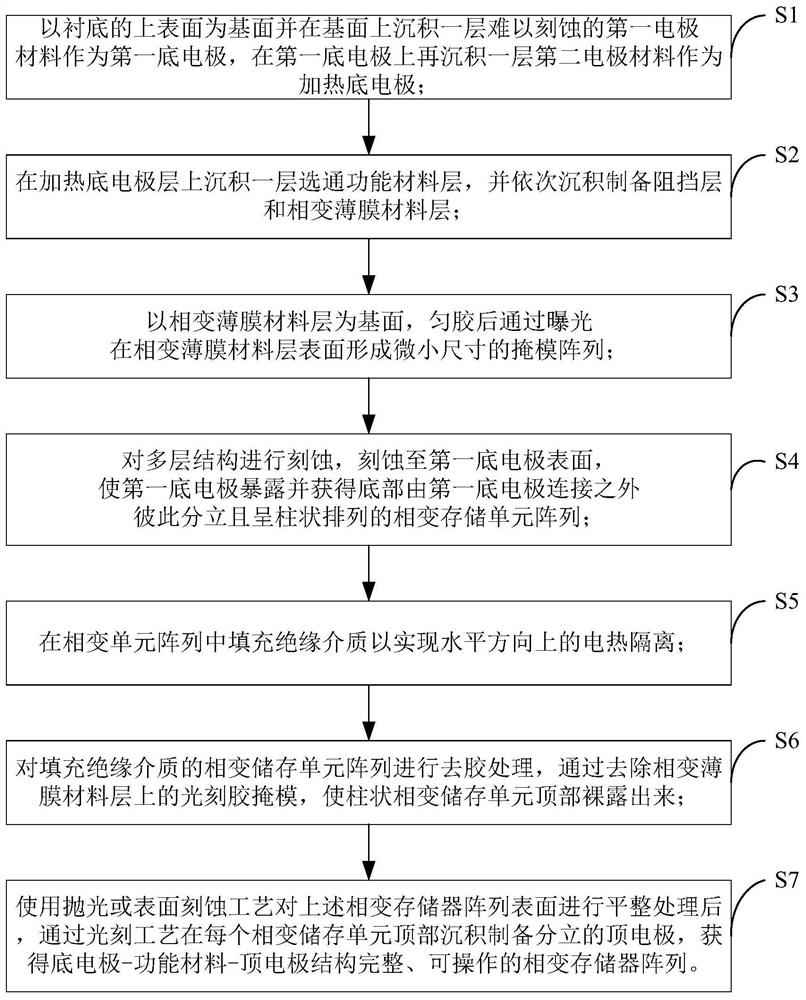

[0047] The present invention provides a method of preparing a phase change memory array. Compared to the conventional process, the present invention adopts the idea of the overall etching of the multilayer film, and does not require each layer to add a photolithography process. The patterning is realized, but the overall pattern etching is performed after the end of the multilayer structure deposition, which can reduce the photolithography step, reduce production cost, improve productivity and yield.

[0048] like figure 1 As shown, the present invention provides a phase change memory array integral preparation process, and specifically includes the following steps:

[0049] S1: The upper surface of the substrate is the base surface, and a layer of first electrode material is deposited on the base surface as a first bottom electrode, and a layer of second electrode material is deposited on the first bottom electrode as a heating electrode; The first bottom electrode material is ...

Embodiment 1

[0065] This Example 1 includes the following steps:

[0066] Step 1: There are SIOs on the surface 2 On the single crystal silicon substrate 1 of the insulating layer, 200 nm Pt is deposited by a magnetron sputtering process as a first bottom electrode 2.

[0067] Step 2: On the basis of step one, 100 nm W is deposited by the magnetron sputtering process as the heating bottom electrode 3.

[0068] Step 3: On the basis of step two, 100 nm gese is deposited by the magnetron sputtering process as the strobe function material layer 4.

[0069] Step 4: On the basis of step three, 10 nm W is deposited by the magnetron sputtering process as the barrier layer 5.

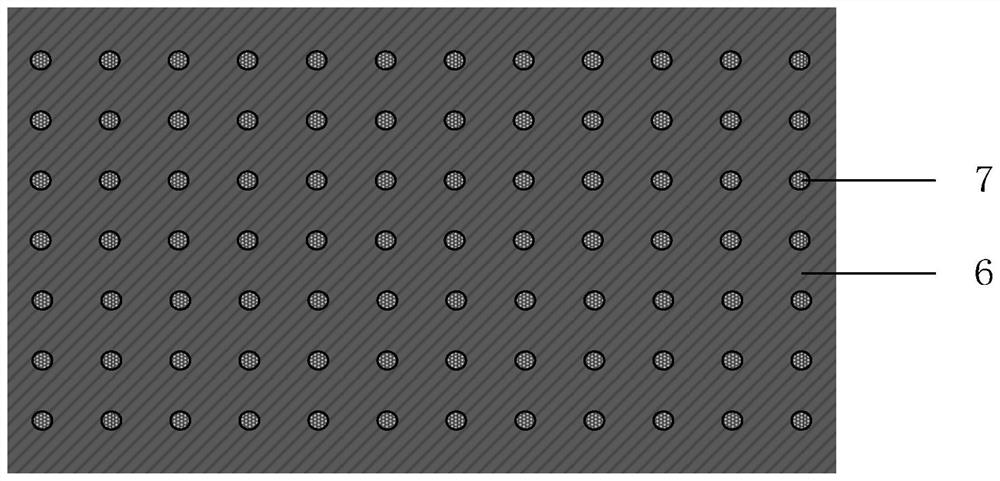

[0070] Step 5: On the basis of step four, 100 nm GE is deposited by magnetron sputtering process. 2 SB 2 TE 5 As the phase change film material layer 6, such as figure 2 Indicated.

[0071] Step 6: On the basis of step five, a uniform photoresist 7 is applied to the layer of the phase change film material using a hierarch.

[00...

Embodiment 2

[0080] This Example 2 includes the following steps:

[0081] Step 1: There are SIOs on the surface 2 On the single crystal silicon substrate of the insulating layer, 200 nm Pt is deposited by a magnetron sputtering process as a first bottom electrode.

[0082] Step 2: On the basis of step one, 100 nm W is deposited by the magnetron sputtering process as the heating electrode.

[0083] Step 3: On the basis of step two, 100 nm GE is deposited by magnetron sputtering process. 2 SB 2 TE 5 As the phase change film material, such as Figure 8 Indicated.

[0084] Step 4: On the basis of step three, the hierarch is used to spin a uniform photoresist on the phase change film material layer.

[0085] Step 5: On the basis of step four, a circular mask array of small sizes is formed on the surface of the phase change film material using electron beam exposure, such as Figure 9 Indicated.

[0086] Step Six: Erregate the multilayer film structure by ICP etching equipment until the first bottom e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com