Terbutaline impulse formulation and preparation method thereof

A terbutaline and pulse technology, applied in the field of terbutaline pulse preparation and its preparation, can solve the problems of increasing adverse reactions, affecting sleep, waste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Recipe 1:

[0050]

[0051] 100 pieces

[0052] Take terbutaline sulfate, mannitol, and L-HPC to pass through a 80-mesh sieve, and mix evenly; take starch, add 10 mL of water to boil, let it cool to make starch slurry, add mixed raw and auxiliary materials to prepare soft materials, and pass through 16 mesh Sieve and granulate, dry at 65°C for 4 hours, granulate with 18 mesh, add magnesium stearate and mix. Use a 5.0mm shallow arc punch as a die, and press on a tablet press (TDP single-punch tablet press) to obtain a tablet core. Tablet weight 101mg, hardness 3.5±0.5kg.

[0053]

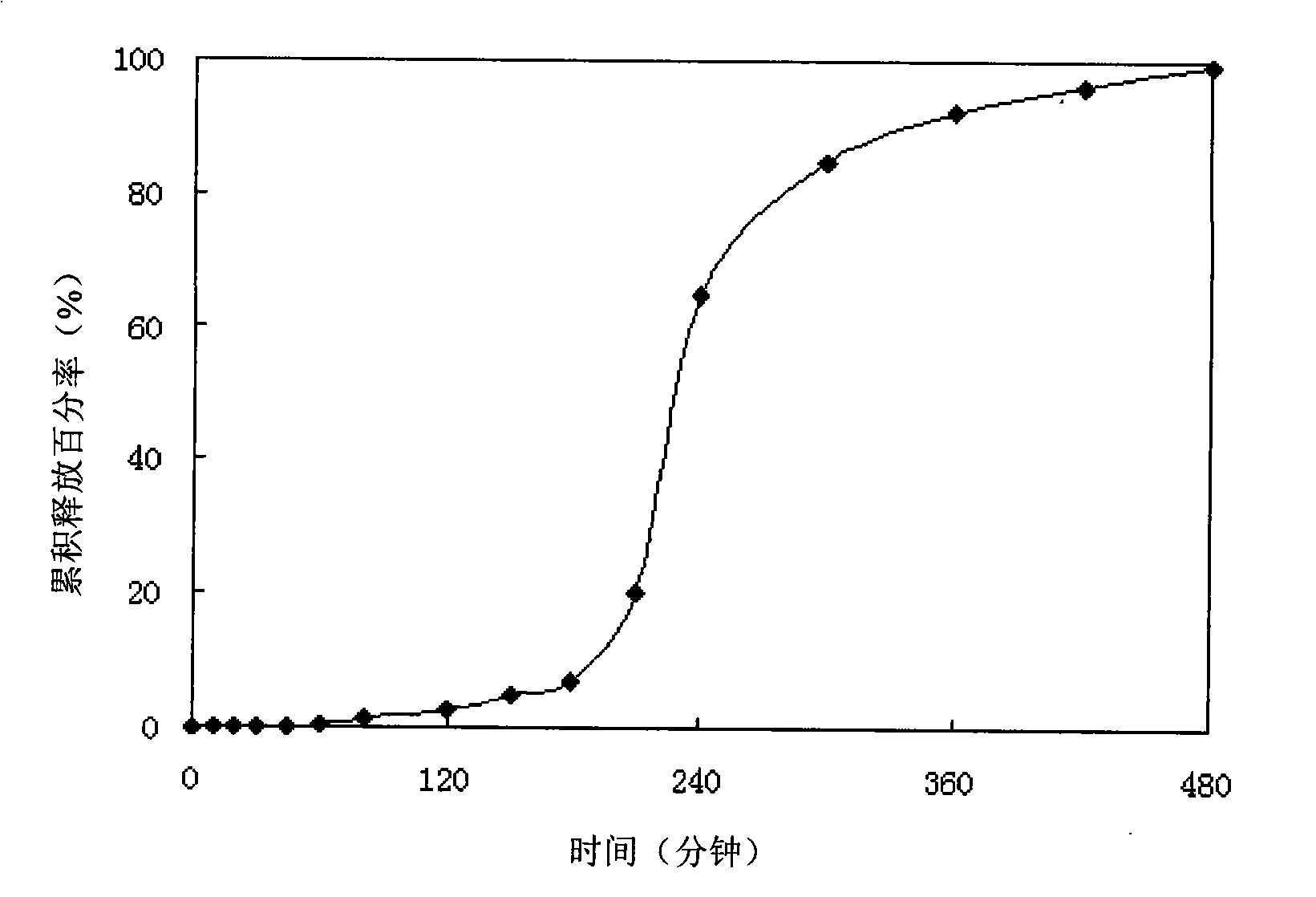

[0054] Suspend hydroxymethylcellulose, carnauba wax, talcum powder, and polyethylene glycol in 20mL of water to make a coating solution; place the tablet core in the coating pan, adjust the rolling coating pan (BY300A type coating pan) Coating pan) angle is 30 degrees, rotating speed is 30rpm, add the coating solution in the spray gun and spray it on t...

Embodiment 2

[0059] Recipe 2:

[0060]

[0061] 100 pieces

[0062] Take terbutaline sulfate, starch, PVPP and potassium chloride and pass through 80-mesh sieve respectively, mix well, take povidone k29 and dissolve in 10mL of ethanol, add mixed raw and auxiliary materials to make soft material, pass through 16-mesh sieve to granulate , dried at 65°C for 3 hours, granulated with 18 mesh, mixed with magnesium stearate. Use a 5.0mm shallow arc punch as a die, and press a tablet machine to obtain tablet cores. Tablet weight 102mg, hardness 4.5±0.5kg.

[0063]

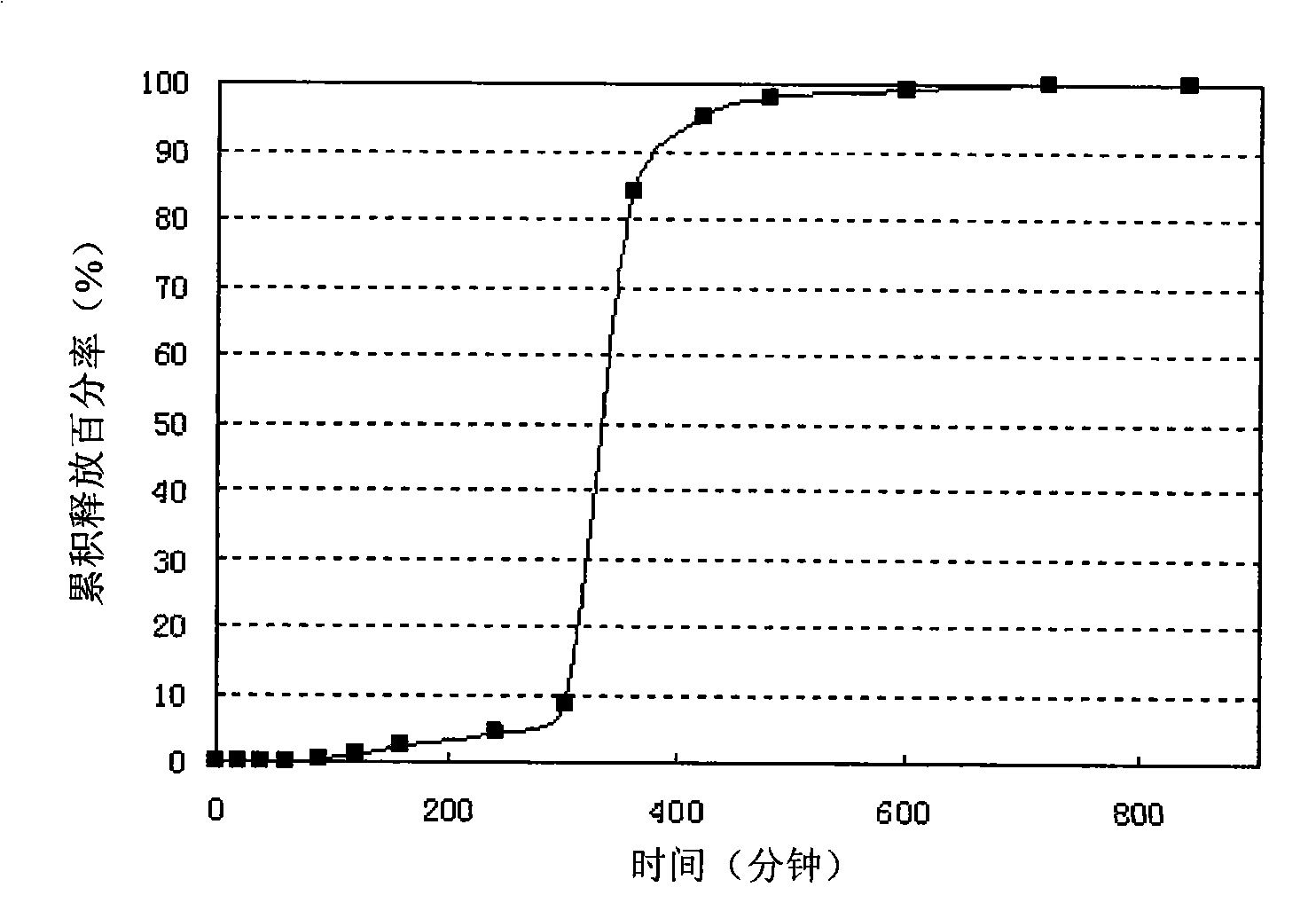

[0064] Hydroxyethyl cellulose, ethyl cellulose, glycerol monostearate, triethyl citrate are dissolved in 50mL of ethanol to make coating solution; the tablet core is placed in a fluidized bed, and the airflow is introduced, The tablet core is in a fluidized state by the rapidly rising airflow, the coating liquid is input into the fluidized bed and atomized, so that a layer of coating material ...

Embodiment 3

[0067] Recipe 3:

[0068]

[0069] 100 pieces

[0070] Take terbutaline sulfate, microcrystalline cellulose PH101, CCNa, povidone k29, micropowder silica gel, and sorbitol and pass through 80-mesh sieve respectively, mix evenly, and use the method of powder direct compression, and use 5.0mm shallow arc punching Punching dies to make tablet cores. Tablet weight 102mg, hardness 3.5±0.5kg.

[0071]

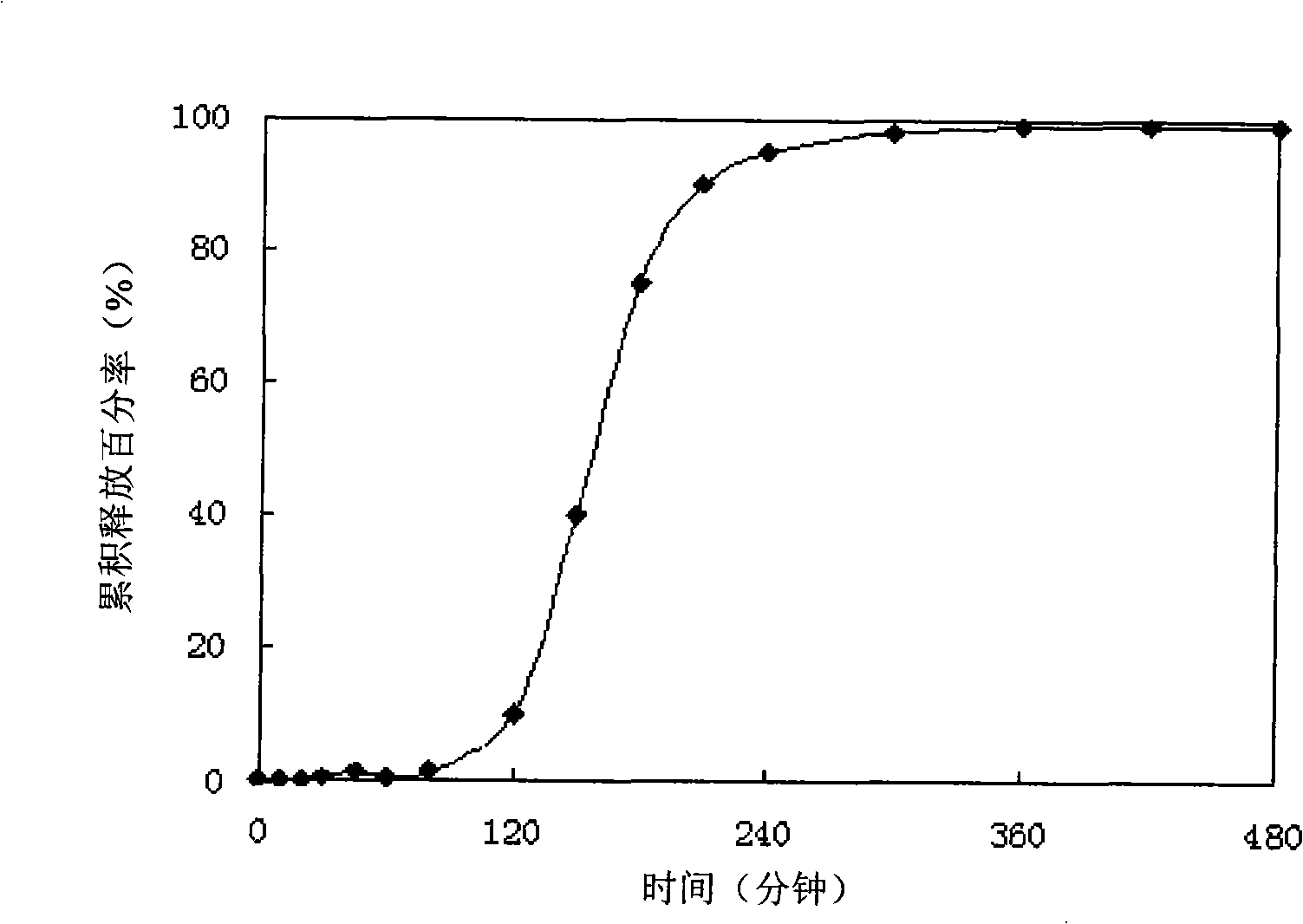

[0072] Mix polyethylene glycol, beeswax, glycerin monostearate, glycerin triacetate and other components, heat and melt in a water bath at 65°C, mix well, cool slowly at room temperature to solidify, grind and pulverize ;Take 10.2mg of coating material and a piece of prepared tablet core, directly dry-press the coating on the tablet machine, the tablet weight is 112.2mg, the hardness is 5.5±0.5kg, and the weight gain of the coating is 10%, which is to make terbu sulfate Taline Pulse Tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sheet weight | aaaaa | aaaaa |

| Sheet weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com