Pr3+doped high-density scintillation glass and preparation method thereof

A scintillation glass, high-density technology, applied in the field of high-density scintillation glass, can solve the problems of slow research progress of scintillation glass, low light yield and density of scintillation glass, and not widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Using Bi 2 o 3 、H 3 BO 3 , SiO 2 As the main raw material, add a small amount of oxidant Sb 2 o 3 and the active ion Pr 3+ (in Pr 6 o 11 introduction), the component design is shown in Table 1.

[0015] The glass composition (mol%) of table 1 embodiment 1

[0016]

[0017] The present embodiment batches 30g altogether, and each component quality is as follows table 2.

[0018] The mass proportion (g) of the glass component of table 2 embodiment 1

[0019]

[0020] According to the above ratio, after mixing the weighed raw materials evenly, the traditional melting-cooling method is used for melting. Pour the batch material into an alumina crucible and seal it, and keep it warm at 1200°C for about 0.5h. After the glass liquid is clarified, pour it into a preheated steel mold, and then transfer it to an annealing furnace for heat preservation and heat treatment. The annealing temperature is 400 ℃, the time is 1h.

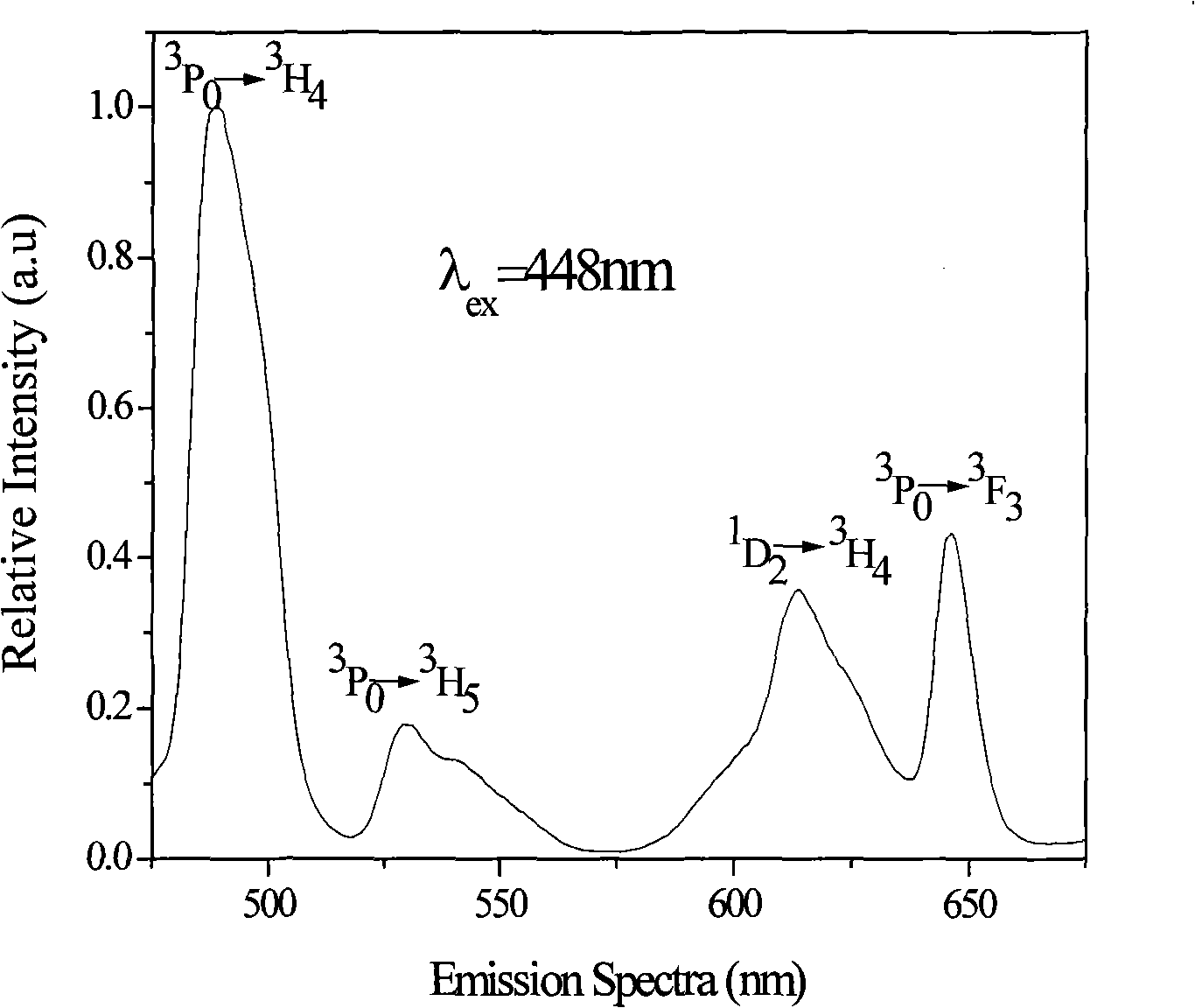

[0021] The density of glass is 6.114g / c...

Embodiment 2~5

[0023] In the following examples, the glass preparation method is the same as Example 1, and the different glass compositions used are shown in Table 3.

[0024] The glass composition (mol%) of table 3 embodiment 2~5

[0025]

[0026] The glass density of table 4 embodiment 2~5

[0027]

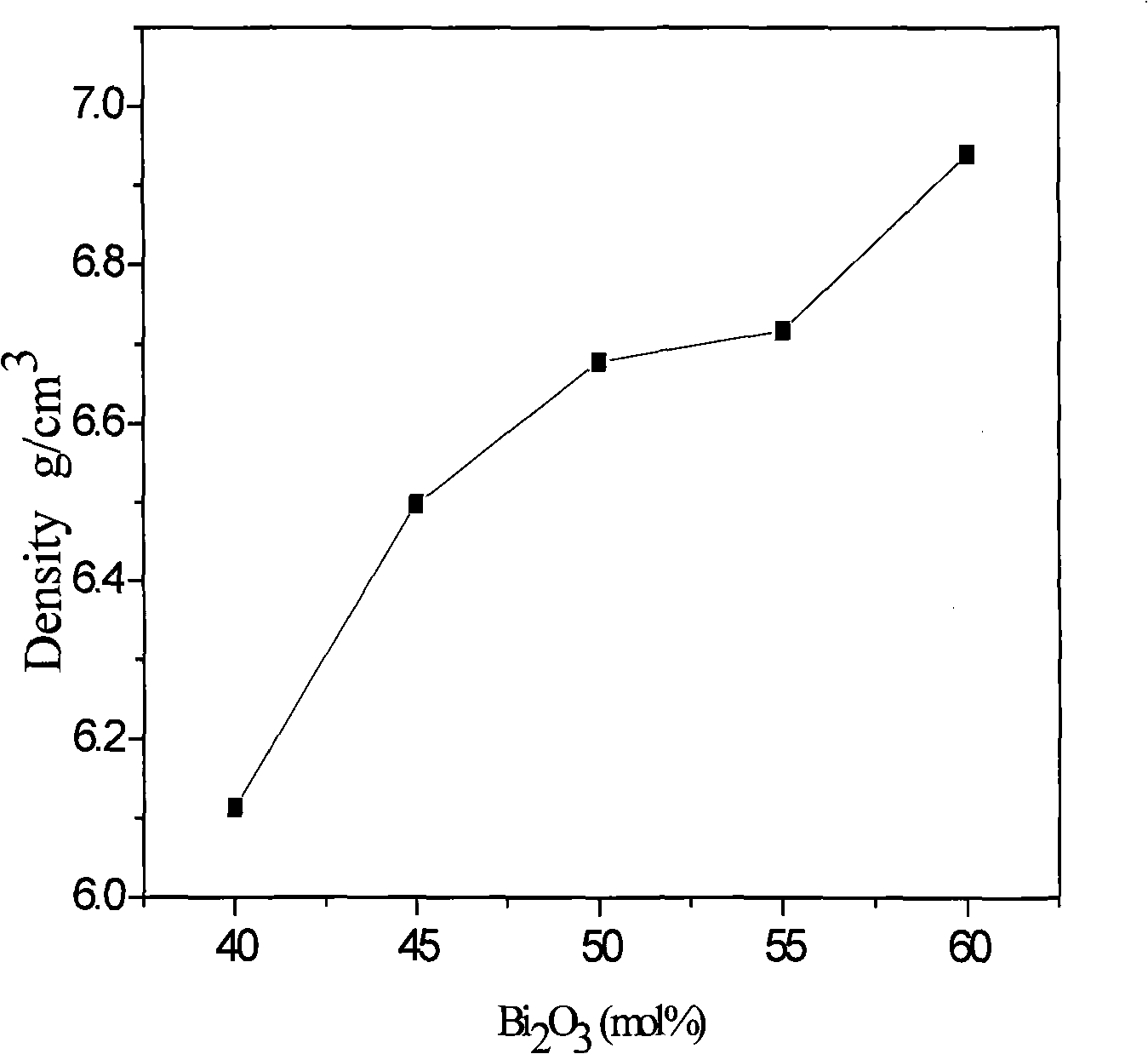

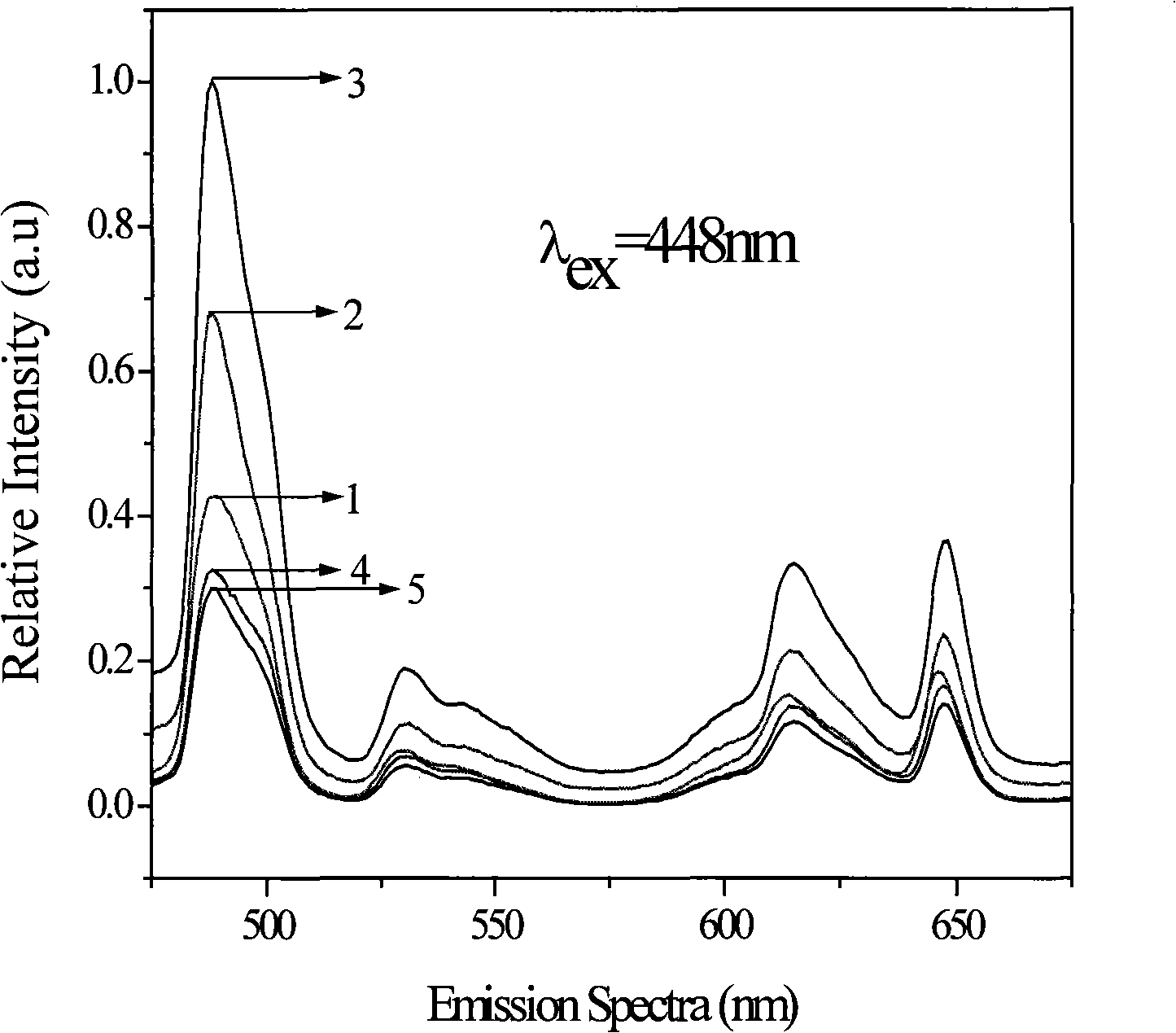

[0028] Embodiment 1~5 glass density and Bi 2 o 3 See accompanying drawing 2 for the content relationship, and refer to accompanying drawing 3 for the emission spectrum.

Embodiment 6~7

[0030] Keep the glass matrix composition constant (embodiment 3: 50Bi 2 o 3 -10B 2 o 3 -40SiO 2 ), changing Pr 3+ The doping concentration and composition are shown in Table 5, and the emission spectrum is shown in Figure 4.

[0031] The glass composition (mol%) of table 5 embodiment 6~7

[0032]

[0033] The emission spectra of Examples 6-7 and 3 are shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com