Method of preparing fucoidin beer

A technology of fucoidan and beer, which is applied in beer fermentation methods, beer brewing, wort preparation, etc., can solve the problems of insufficient development and utilization of brown algae, achieve antiviral effect retention, mild conditions, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

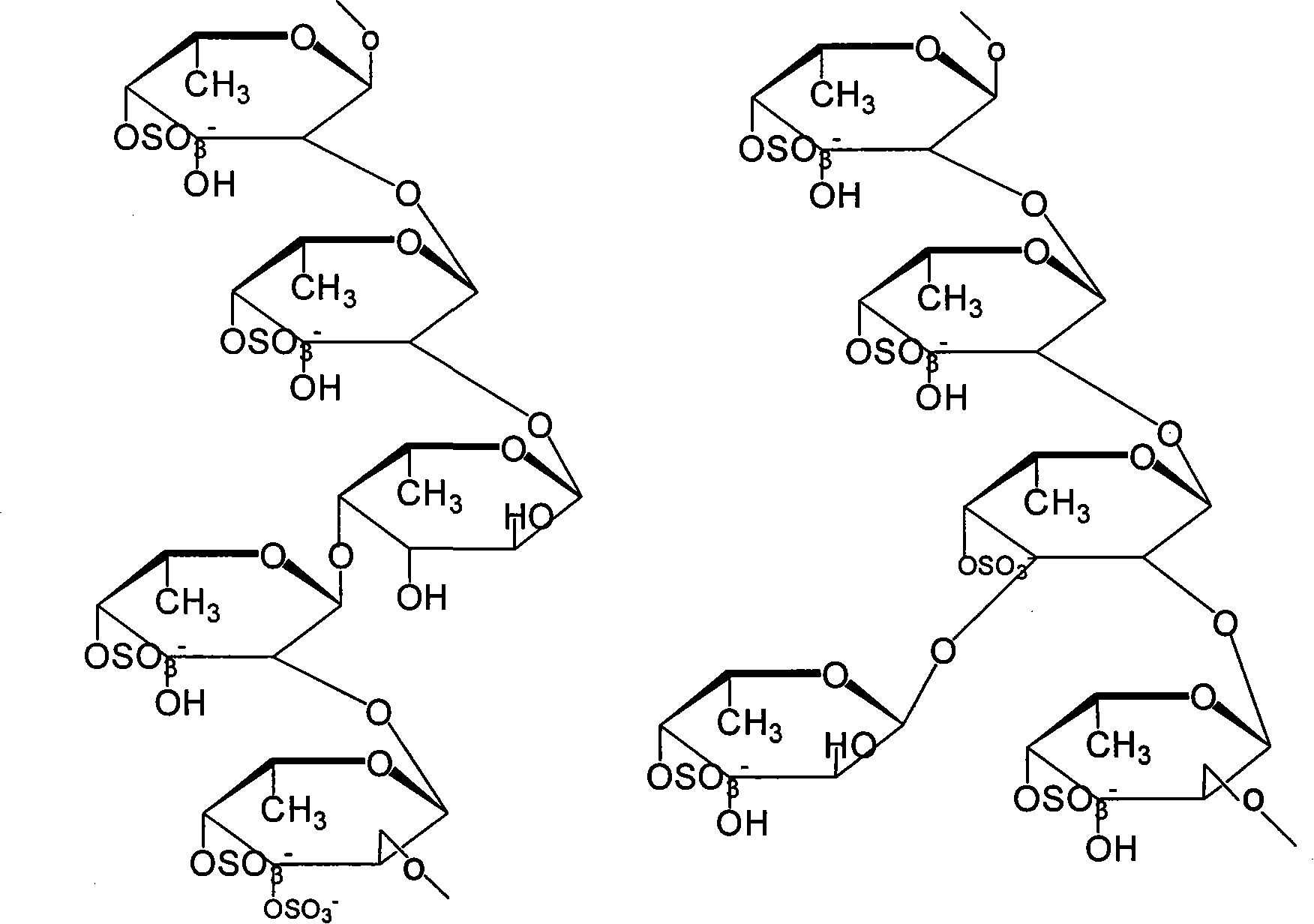

Image

Examples

Embodiment

[0039] Example: a preparation method of fucoidan beer, comprising two steps of separation and extraction from kelp, decolorization, purification of fucoidan and preparation of fucoidan beer:

[0040] The steps of separating, extracting, decolorizing and purifying fucoidan from kelp are as follows:

[0041] 1) Separation and extraction of fucoidan from kelp:

[0042] After the dried kelp has been desilted and dried into kelp algae powder, it is extracted in hot water at 90°C for 11 hours, and the amount of water added is 30ml / g. After centrifugation to obtain the supernatant, adjust the pH to neutral, and concentrate under reduced pressure to the original 1 / 2 of the volume, precipitated with ethanol with a final concentration of 60%, washed twice with anhydrous ether and acetone, and finally dried in vacuum to obtain laminarin;

[0043] 2) Decolorization of fucoidan:

[0044] Adjust the pH to 8.8 with concentrated ammonia water or NaOH solution, and add H2 dropwise below 30°C...

Embodiment 2

[0058] Example 2: Separation, extraction, decolorization and purification of fucoidan, the steps are as follows:

[0059] 1) Separation and extraction from kelp

[0060] Dried kelp is desilted and dried into kelp algae powder, extracted in hot water at 80°C for 11 hours, adding 30ml / g of water, centrifuged to get the supernatant, adjusted to neutral pH, concentrated under reduced pressure to the original volume 1 / 2, precipitated with ethanol with a final concentration of 60%, washed twice with anhydrous ether and acetone, and finally dried in vacuum to obtain the crude laminarin.

[0061] All the other are the same as embodiment 1

Embodiment 3

[0062] Example 3: Separation, extraction, decolorization and purification of fucoidan, the steps are as follows:

[0063] After the dried kelp has been desilted and dried into kelp algae powder, it is extracted in hot water at 90°C for 11 hours, and the amount of water added is 30ml / g. After centrifugation to obtain the supernatant, adjust the pH to neutral, and concentrate under reduced pressure to the original volume. 1 / 2, precipitated with ethanol with a final concentration of 65%, washed twice with anhydrous ether and acetone, decolorized and purified, and finally dried in vacuum to obtain laminarin.

[0064] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com