Biodegradable polyamideimide and preparation thereof

A citric amide imide, biodegradable technology, applied in the field of environmentally friendly materials and biomedical materials, can solve the problems of difficult degradation of nylon, poor hydrophilicity, etc., and achieves easier control of crosslinking degree, high hydrophilicity, Easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

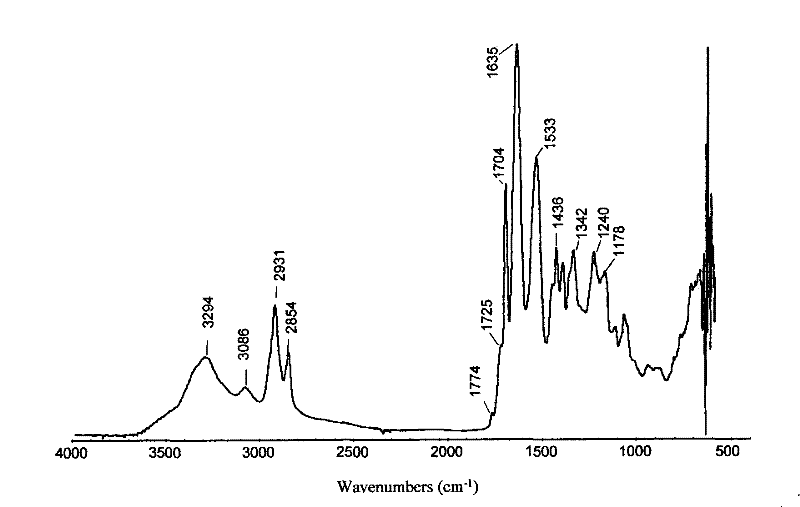

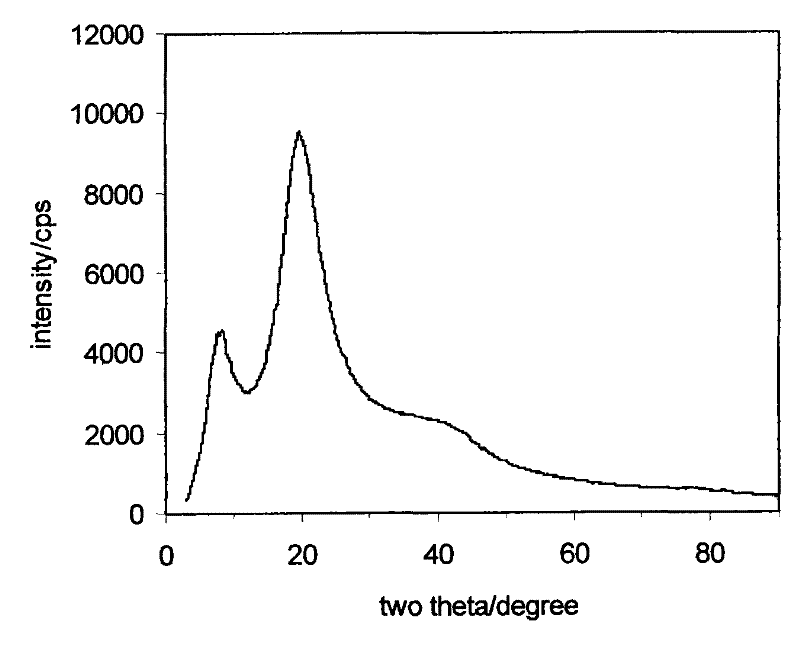

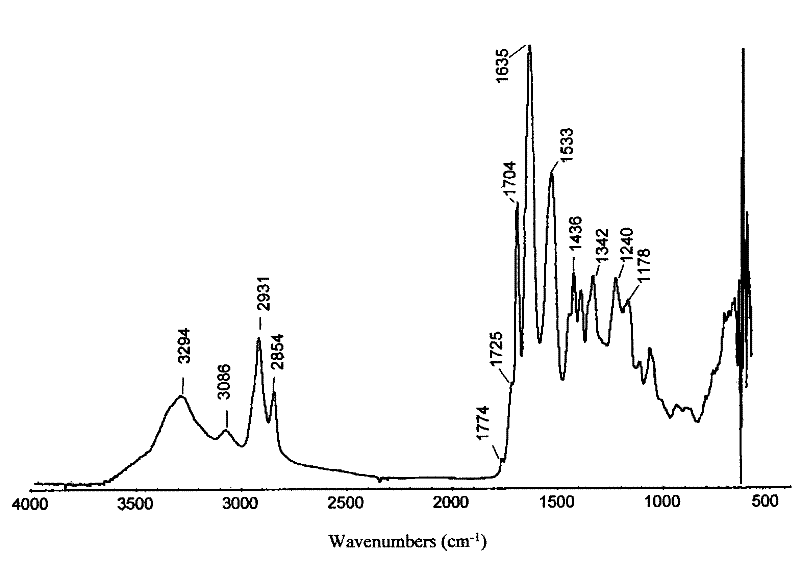

Image

Examples

Embodiment 1

[0044] Mix 10.0ml of tributyl citrate, 5.0ml of 1,6-hexanediamine and 1.0ml of triethylamine into a round-bottomed flask, connect it to a rotary evaporator and evacuate to -0.1MPa, and control the temperature at 50°C After reacting for 6 hours, the prepolymer was obtained. Place it on a clean glass surface while it was hot, spread it evenly, and then vacuum-dry it for 11.5 hours with the temperature controlled at 160°C to obtain polycitric acid amide imide.

Embodiment 2

[0046] Mix 10.0ml of tributyl citrate, 5.0ml of 1,6-hexanediamine and 1.0ml of triethylamine into a round-bottomed flask, connect it to a rotary evaporator, vacuumize to about -0.04MPa, and react at room temperature for 2 hours. Then, heating at 120° C. and continuing the rotation reaction for 2 h to obtain polycitamide imide.

Embodiment 3

[0048] Mix 10.0ml of tributyl citrate, 5.0ml of 1,6-hexanediamine and 1.0ml of triethylamine into a round-bottomed flask, connect it to a rotary evaporator, evacuate to -0.04MPa, and continue heating at 50°C After 12 hours of rotation reaction, polycitamide imide was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com