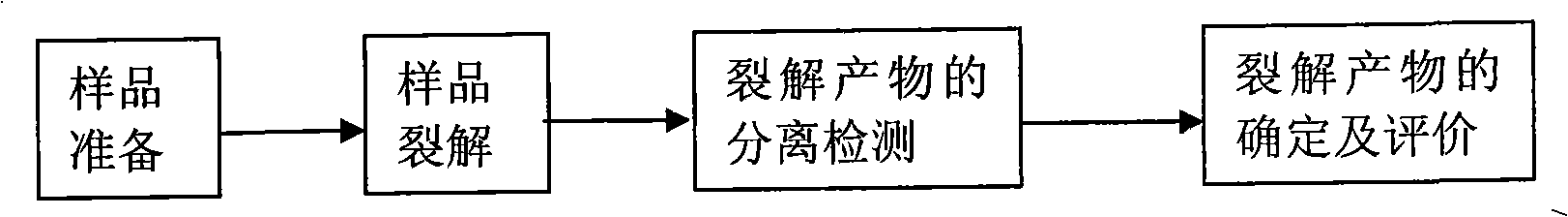

Method for screening fragrant raw material for cigarette based on thermal cracking - gas chromatograph mass spectrogram multiple techniques

A gas chromatography-mass spectrometry, combined technology, applied in the field of tobacco flavor detection, can solve problems such as lack of uniformity, difficult screening of tobacco flavor raw materials, lack of system, etc., and achieve less sample injection, good reproducibility, information A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Weigh 0.1 mg of deoxyfructosine (self-made, colorless and odorless white solid powder at room temperature, purity > 99%), put it into the middle section of the cracking tube of the probe of CDS PYROPROBE2000 cracking instrument, fill and fix it with quartz wool, and crack the sample Experiment: The initial temperature of the pyrolysis instrument probe: 100°C; the heating rate: 10°C / millisecond; the final temperature rises to 300, 600, and 900°C respectively, the pyrolysis time is 5s, and the volume percentage of oxygen in the pyrolysis atmosphere is 0% ;

[0017] 2. The GC analysis conditions for separation and detection of pyrolysis products by using GC-MS coupled with a pyrolysis instrument are as follows: inlet temperature: 270°C; carrier gas: He, flow rate 1.0ml / min, chromatographic column HP-5MS ( 60m×0.25mm.×0.25μm), split ratio 10:1; hold for 40min; GC / MS temperature program: initial temperature 70℃, final temperature 270℃, heating rate 2℃ / mi;

[0018] 3. The...

Embodiment 2

[0022] 1. Weigh 1 mg of self-made glucose acetate, put the sample into the middle section of the pyrolysis tube of the pyrolysis instrument probe and fix it with quartz wool; the control conditions during the pyrolysis process of the CDS PYROPROBE2000 pyrolysis instrument are: the initial temperature of the pyrolysis instrument probe : 50°C; heating rate: 20°C / millisecond; the final temperature rises to 400°C and 800°C respectively, the pyrolysis time is 10s, and the volume percentage of oxygen in the pyrolysis atmosphere is 20%;

[0023] 2. The GC analysis conditions for separation and detection of pyrolysis products by GC-MS are as follows: inlet temperature: 250°C; carrier gas: He, flow rate 0.8ml / min, chromatographic column: HP-FFAP column (30m×0.25 mm×0.25μm); split ratio 15:1; hold for 30min; GC / MS temperature program: initial temperature 50°C, final temperature 220°C, heating rate 5°C / min;

[0024] 3. The mass spectrometry conditions for separation and detection of pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com