Cement concrete air entraining agent and method for preparing same

A cement concrete and air-entraining agent technology, which is applied in the field of building materials, can solve problems affecting product quality, poor solubility, poor storage stability, etc., and achieve the effects of good bubble stability, stable reaction process, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Get 10 kilograms of rosin powder, 10 kilograms of sodium hydroxide solution of 40% concentration, 15 kilograms of hydrogen peroxide of 30% concentration, 10 kilograms of potassium permanganate solution of 10% concentration, 5 kilograms of sulfuric acid solution of 20% concentration, 80 kilograms of tap water.

[0014] First put sodium hydroxide, hydrogen peroxide, sulfuric acid, potassium permanganate solution and water into the reaction kettle, heat to 80°C, then slowly add rosin powder, stir while adding, and then stir for 30 minutes after adding rosin powder to obtain a solution The product is the air-entraining agent prepared in this example.

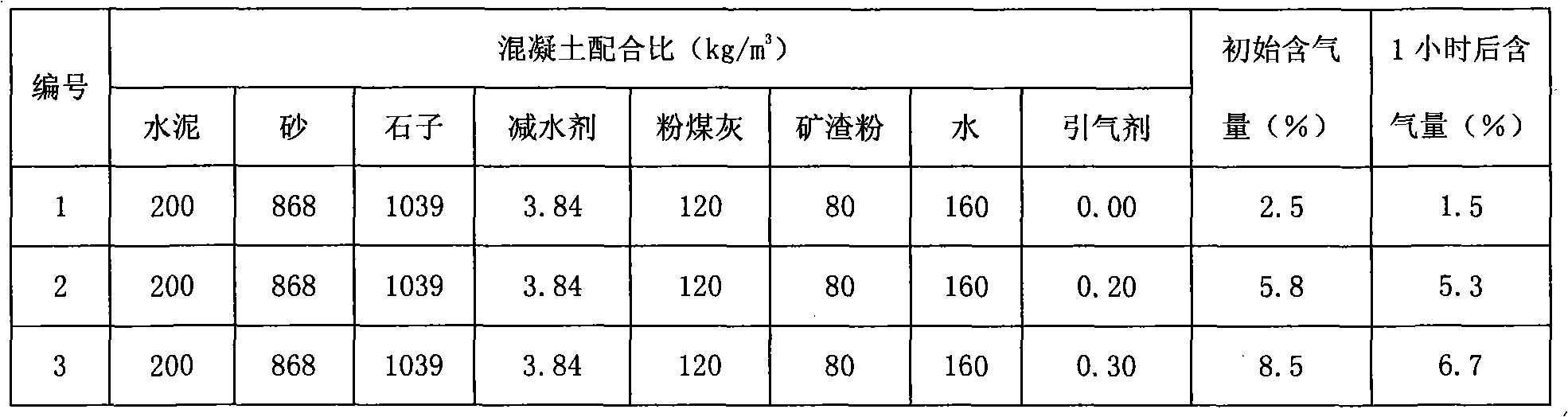

[0015] Detection of foam stabilization effect of air-entraining agent

[0016] Test with concrete:

[0017] Raw materials: cement: PO42.5MPa; sand: medium sand; gravel: continuous gradation, maximum particle size 25mm; water reducer: naphthalene series high-efficiency water reducer; fly ash: class II; finely ground slag powd...

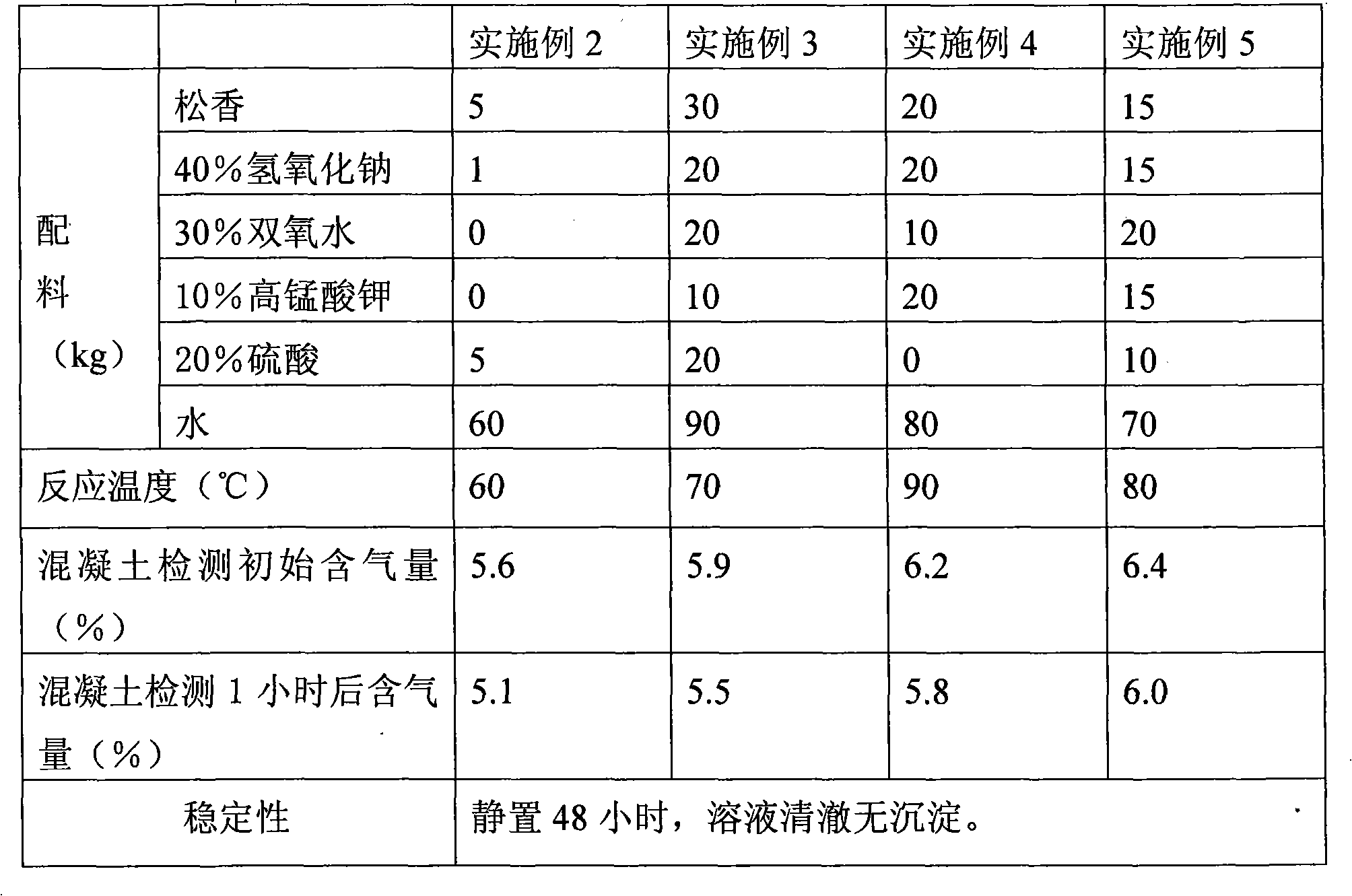

Embodiment 2~ Embodiment 5

[0024] According to the processing and detection method of embodiment 1, air-entraining agent is prepared and detected by raw material ratio and conditions shown in table 2:

[0025] Table 2 Embodiment 2~5 air-entraining agent ingredients, preparation and detection

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com