Nonwoven fabric sheet having cleaning function

A technology of washing effect and non-woven fabrics, which is applied in the direction of detergent materials, detergent compositions, non-surface-active detergent compositions, etc., can solve the problems of non-woven fabrics such as poor strength, high transportation costs, and heavy weight, and achieve Enhanced softness, improved washing effect, and improved retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

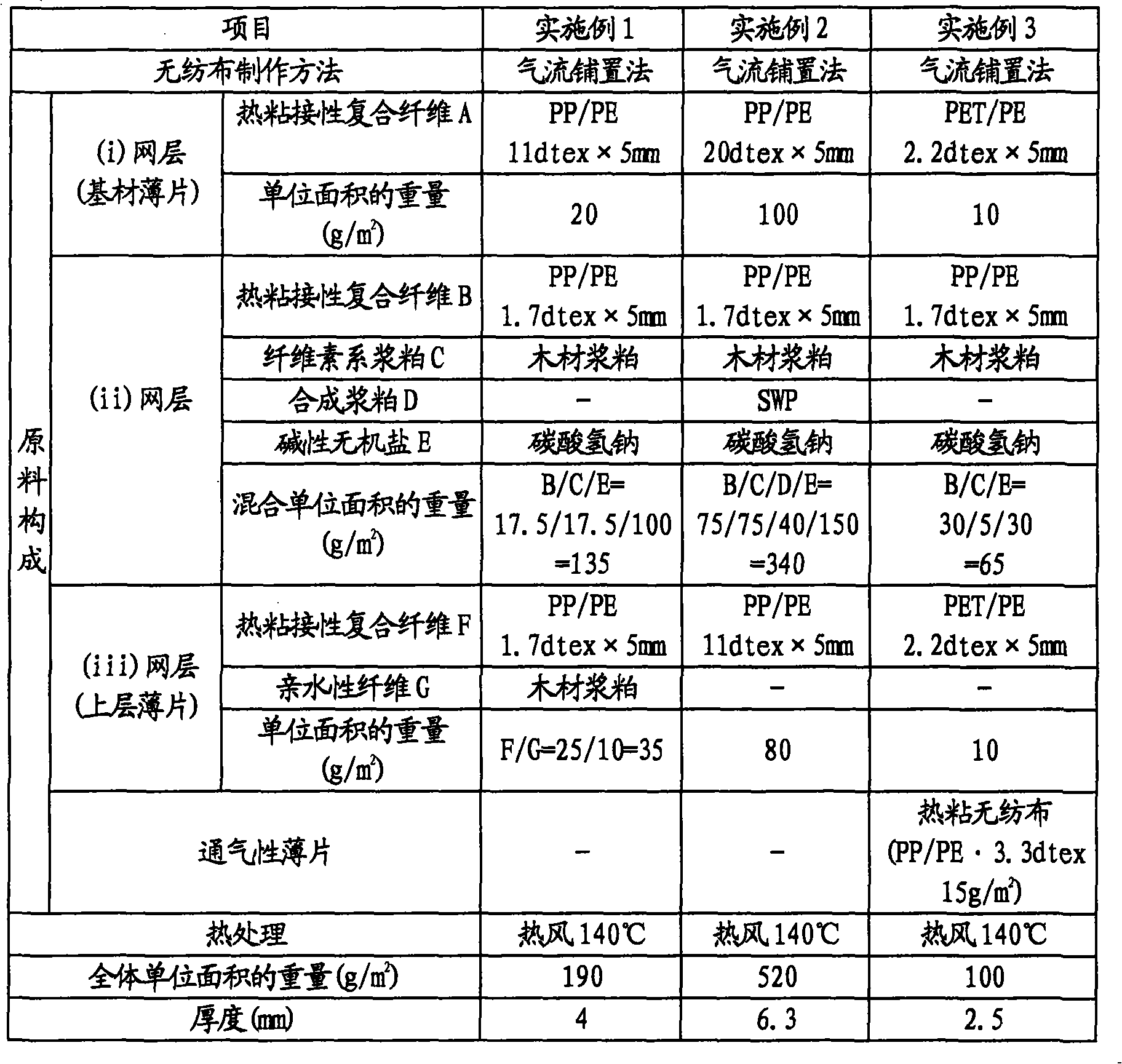

Embodiment 1

[0107] PP(polypropylene) / PE(polyethylene)-based composite fiber 11dtex×5mm (manufactured by Chitsuso Co., Ltd.) is air-laid as (i) mesh layer (substrate sheet) and formed on a net to reach 20g / m 2 . Next, PP / PE-based composite fiber 1.7dtex×5mm (manufactured by Chitsuso Co., Ltd.), pulverized product of wood pulp (manufactured by Weyerhaeuser Co., Ltd. NB416) and sodium bicarbonate [manufactured by Tokuyama Co., Ltd.] were mixed to obtain PP / PE PE-based composite fiber 1.7dtex×5mm (manufactured by Chitsuso Co., Ltd.) 17.5g / m 2 17.5 g / m of pulverized wood pulp (NB416 manufactured by Weyerhaeuser Co., Ltd.) 2 , Sodium bicarbonate [manufactured by (stock) Tokuyama] 100g / m 2 , will add up to 135g / m 2 The (ii) mesh layer is formed on the above-mentioned (i) mesh layer by an air-laid method. Furthermore, on top of this, PP / PE composite fiber 1.7dtex×5mm and wood pulp were mixed so that PP / PE composite fiber 1.7dtex×5mm became 25g / m 2 , Wood pulp up to 10g / m 2 As (iii) mesh lay...

Embodiment 2

[0109] PP / PE-based composite fiber 20dtex×5mm (manufactured by Chitsuso Co., Ltd.) is air-laid on a net to achieve 100g / m 2 As (i) mesh layer (substrate sheet). Next, mix PP / PE composite fiber 1.7dtex×5mm, wood pulp, synthetic pulp (Mitsui Chemicals Co., Ltd. SWP.E790) and sodium bicarbonate to make PP / PE composite fiber 1.7dtex× 5mm is 75g / m 2 , Wood pulp is 75g / m 2 , Synthetic pulp (Mitsui Chemicals (Co., Ltd.). SWP.E790) is 40g / m 2 , Sodium bicarbonate is 150g / m 2 , form a total of 340g / m on the above (i) mesh layer by air laying method 2 The (ii) network layer. Furthermore, PP / PE-based composite fibers 11dtex×5mm are formed by air laying method to reach 80g / m 2 As (iii) network layer. Will the whole 520g / m 2 The air-laid net is heated by a hot air suction heating furnace at 140°C and integrated. The obtained nonwoven fabric with a thickness of 6.3 mm was wetted with water and used for cleaning a cooking stove, and as a result, contaminants were cleanly removed. F...

Embodiment 3

[0111] PP / PE-based composite fiber 3.3dtex×51mm (manufactured by Chitsuso Co., Ltd.) is reticulated by carding, and heated and integrated in a hot air suction heating furnace at 136°C to obtain a weight per unit area of 15g / m 2 Hot-bonded dry-laid non-woven fabric. This dry-laid nonwoven fabric was placed on a mesh conveyor belt, and PET (polyethylene terephthalate) / PE-based composite fiber 2.2dtex×5mm (manufactured by Teijin Textile Co., Ltd.) Formed by air laying method to reach 10g / m 2 As (i) mesh layer (substrate sheet). Next, mix PP / PE composite fiber 1.7dtex×5mm, wood pulp and sodium bicarbonate so that PP / PE composite fiber 1.7dtex×5mm is 30g / m 2 , Wood pulp is 5g / m 2 , Sodium bicarbonate is 30g / m 2 , form a total of 65g / m on the above (i) mesh layer by air laying method 2 The (ii) network layer. Furthermore, on it, PET / PE-based composite fibers 2.2dtex×5mm are formed by air laying method to achieve 10g / m 2 As (iii) network layer. The whole 100g / m 2 The compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com