Method and device for preparing potassium manganate by channelization pressurization

A potassium manganate, pipeline technology, applied in the direction of manganate/permanganate, etc., can solve the problems of ineffective control of pollution, strict quality requirements of manganese ore powder, reduction of material consumption and energy consumption, etc., to achieve the reaction time Shortening, good flow performance and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

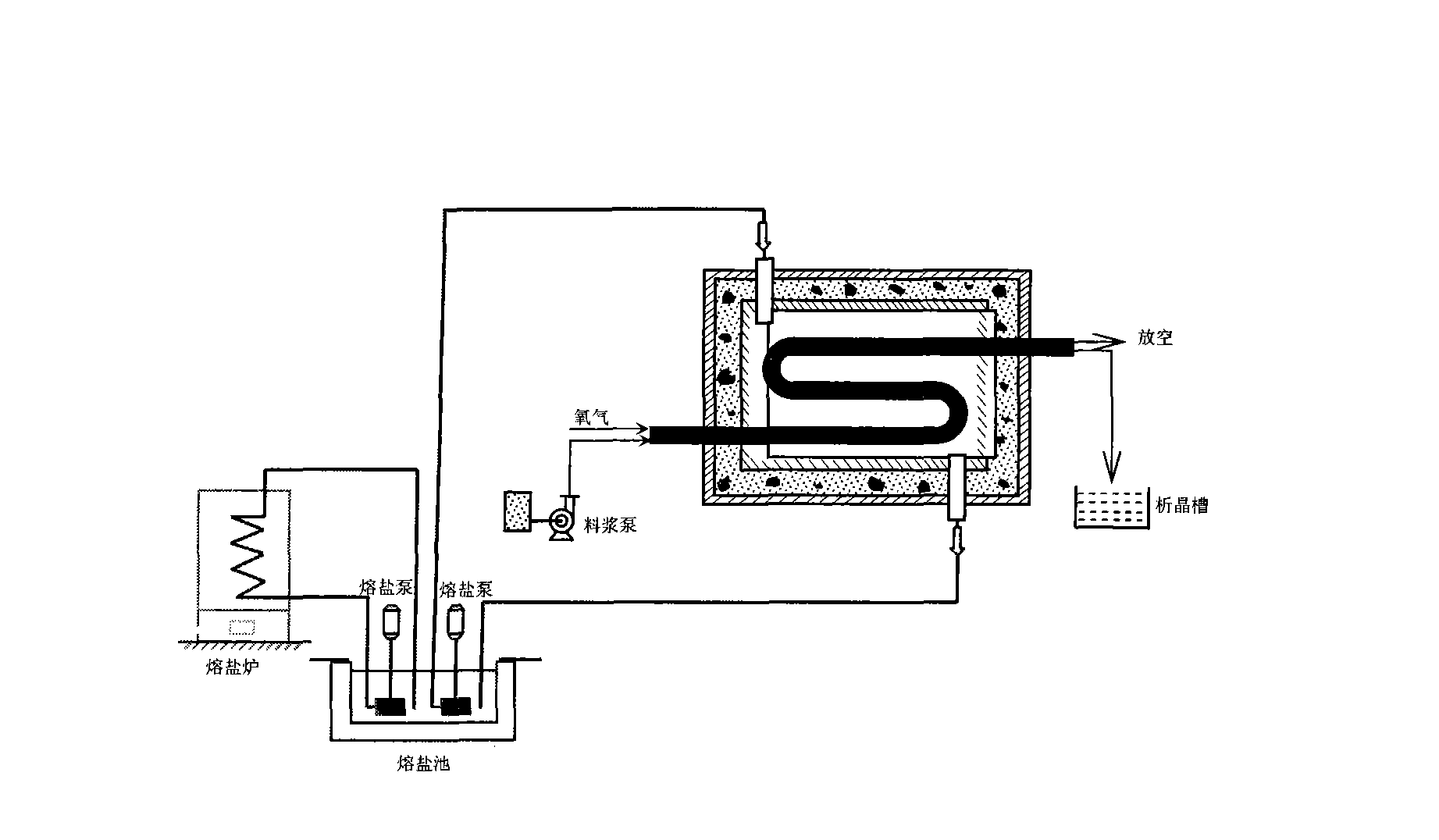

Image

Examples

Embodiment 1

[0018] Embodiment 1: Potassium hydroxide and water are mixed with the alkali solution that mass concentration is 50%, and add manganese powder in alkali solution by mass parts manganese: potassium hydroxide=1: 13 and be mixed with slurry;

[0019] Pump the slurry into a pressurized pipeline reactor, let the slurry flow through the reactor along the pipeline, and at the same time introduce industrial pure oxygen for continuous oxidation reaction, control the residence time of the slurry in the pipeline for 2 hours, and the temperature of the pipeline at 190°C. Pressure 0.6Mpa;

[0020] The slurry after the reaction is cooled and separated in a crystallization tank to obtain potassium manganate crystals and mother liquor, and the mother liquor is returned to prepare slurry.

Embodiment 2

[0021] Embodiment 2: Potassium hydroxide and water are mixed into the alkali solution that mass concentration is 50%, and add manganese powder in alkali solution by mass parts manganese: potassium hydroxide=1:9 and be mixed with slurry;

[0022] Pump the slurry into a pressurized pipeline reactor, let the slurry flow through the reactor along the pipeline, and at the same time introduce industrial pure oxygen for continuous oxidation reaction, control the residence time of the slurry in the pipeline for 2h, and the temperature of the pipeline at 220°C. Pressure 0.8Mpa;

[0023] The slurry after the reaction is cooled and separated in a crystallization tank to obtain potassium manganate crystals and mother liquor, and the mother liquor is returned to prepare slurry.

Embodiment 3

[0024] Embodiment 3: Potassium hydroxide and water are mixed into the alkali solution that mass concentration is 50%, and add manganese powder in alkali solution by mass parts manganese: potassium hydroxide=1: 10 and be mixed with slurry;

[0025] Pump the slurry into the pressurized pipeline reactor, let the slurry flow through the reactor along the pipeline, and at the same time introduce industrial pure oxygen for continuous oxidation reaction, control the residence time of the slurry in the pipeline for 3h, and the temperature of the pipeline at 240°C, Pressure 0.4Mpa;

[0026] The slurry after the reaction is cooled and separated in a crystallization tank to obtain potassium manganate crystals and mother liquor, and the mother liquor is returned to prepare slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com