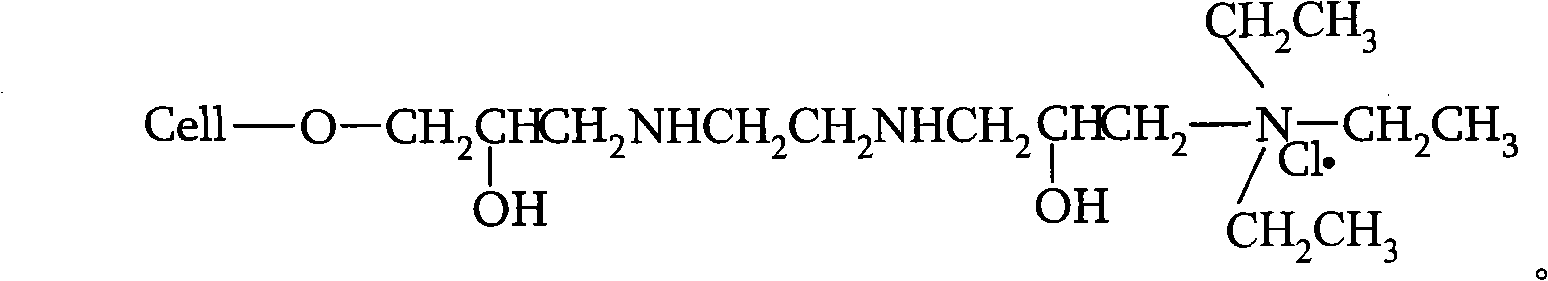

Method for preparing quaternary amines salt cationic adsorption agent with plant of high cellulose content

A high-cellulose, cationic technology, applied in the field of environment and chemistry, to achieve the effects of simple production process, good product stability and less secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

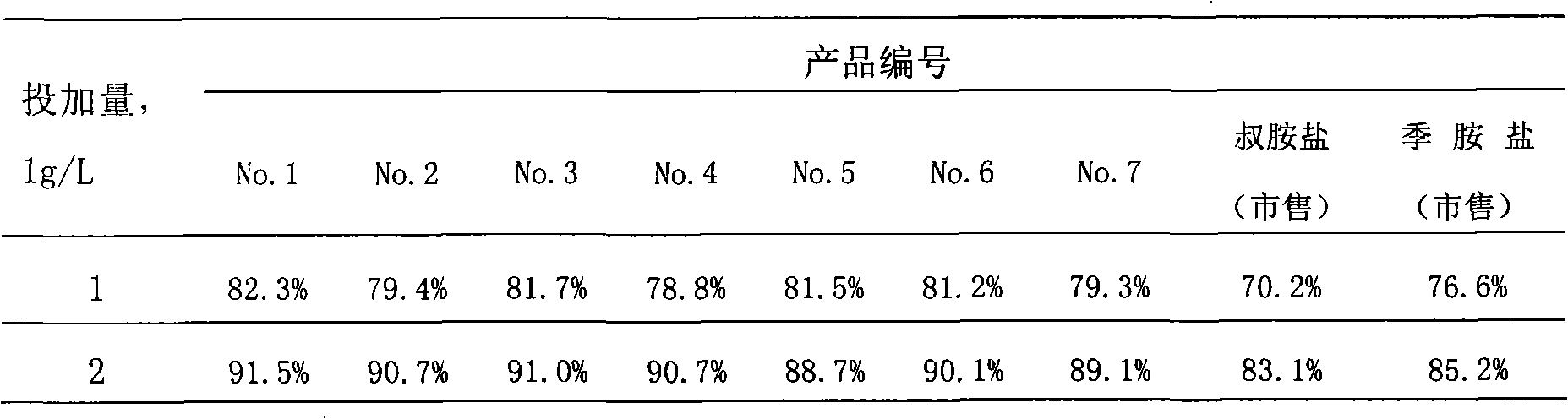

Examples

Embodiment 1

[0029] Stirring and reacting Phyllostachys arundis with epichlorohydrin, adding cross-linking agent ethylenediamine, and then adding triethylamine solution, the proportioning ratio between them is Phyllostachys arundis: Epichlorohydrin: Ethylenediamine: Triethylamine solution =4g: 10mL: 3mL: 10mL, prepared the quaternary ammonium salt cationic adsorbent of Phyllostachys arundis. The product is represented by No.1. The specific preparation method is as follows:

[0030] (1) Take 4 g of Arundo donax with a particle size of 500 μm in a 250 mL three-necked flask, add 10 mL of epichlorohydrin, stir and add 10 mL of medium N,N-dimethylformamide, and stir at 80°C for 30 minutes .

[0031] (2) Take 3 mL of cross-linking agent ethylenediamine and add it to the above-mentioned 250 mL three-neck flask to continue stirring and reacting for 30 min, and the temperature is controlled at 80°C.

[0032] (3) Add 10 mL of triethylamine solution with a concentration of 99% by mass, the reactio...

Embodiment 2

[0035] Wheat straw and epichlorohydrin are stirred and reacted, and cross-linking agent diethylenetriamine is added, and then triethylamine solution is added, and the ingredient ratio between them is wheat straw: epichlorohydrin: diethylenetriamine: triethylene Amine solution = 4g: 10mL: 4mL: 10mL, the wheat straw quaternary ammonium salt cationic adsorbent was prepared. The product is represented by No.2.

[0036] The specific preparation method is the same as in Example 1, except that the cross-linking agent added is 4 mL of diethylenetriamine, and the reaction temperature is 80°C. The obtained quaternary ammonium salt cationic adsorbent has a tan powdery appearance and a Zeta potential of 29.9mv. The pH value of the aqueous solution is 5.04.

Embodiment 3

[0038]Stirring and reacting Phyllostachys arundis and epichlorohydrin, and adding cross-linking agent diethylenetriamine, then adding triethylamine solution, the proportioning ratio between them is Phyllostachys arundis: Epichlorohydrin: Diethylenetriamine: Triethylene Amine solution = 4g: 10mL: 3mL: 15mL, the quaternary ammonium salt cationic adsorbent of Phyllostachys arundis is prepared. The product is represented by No.3.

[0039] The specific preparation method is as in Example 1, except that the added triethylamine is 15 mL, the cross-linking agent is triethylenetetramine and the cross-linking agent is 3 ml, and the reaction temperature is 75° C. The obtained quaternary ammonium salt cationic adsorbent has a yellow powder appearance and a Zeta potential of 32.8mv. The pH value of the aqueous solution is 4.27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com