Red fluorescent powder for white radiation LED and preparation thereof

A technology for red phosphor powder and white light, applied in the field of red phosphor powder and its preparation, can solve the problems of low luminous efficiency, high sintering temperature and high production cost, and achieve the effects of simple preparation method, good radiation resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

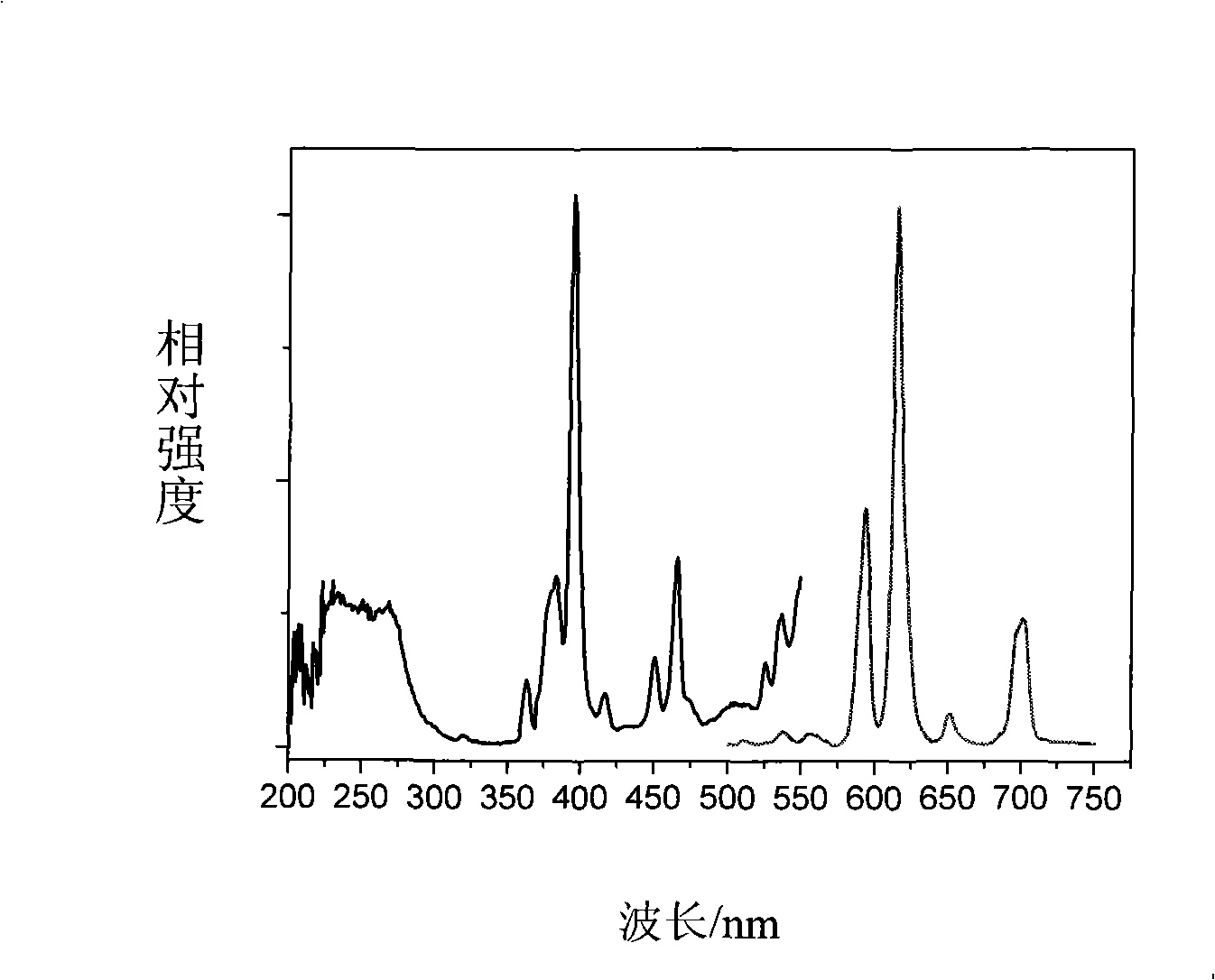

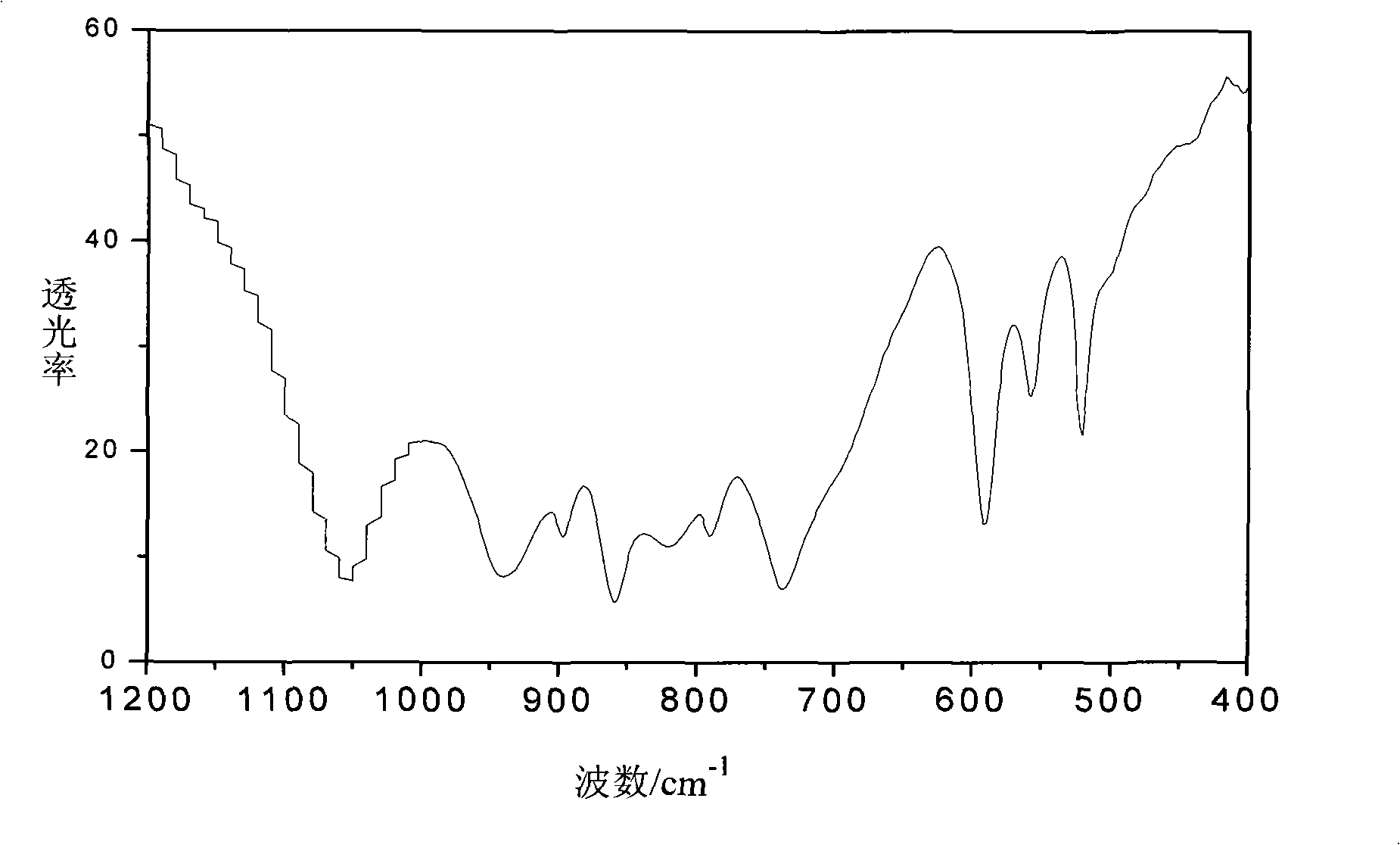

Image

Examples

Embodiment 1

[0018] The chemical expression of the red fluorescent powder of the present embodiment is:

[0019] Li 0.30 K 1.70 SM 0.022 Bi 0.90 (P 0.96 Nb 0.04 o 4 )(W 0.37 Mo 0.63 o 4 ):0.07gEu 3+ Its preparation method is as follows:

[0020] ①Weigh 1.12g of Li 2 CO 3 , 3.70g of K 2 CO 3 , 0.40g of Sm 2 o 3 , 20.97g Bi 2 o 3 , 13.10g of KH 2 PO 4 , 0.55g of Nb 2 o 5 , 10.0g of (NH 4 ) 6 W 7 o 24 ·6H 2 O, 12.35g of (NH 4 ) 2 MoO 4 and 1.40g of Eu 2 o 3 and researched separately. The above raw materials are analytically pure, and the purity of the rare earth oxide is 99.99%.

[0021] ②Mix the above raw materials evenly, then place them in an oven to fully dry to remove water, and grind them again.

[0022] ③Put the mixed material into a corundum crucible and put it into a muffle furnace, and sinter at 680°C for 6h in an air atmosphere.

[0023] ④ The obtained sintered product is crushed, powder-selected, acid-washed, alkali-washed, water-washed, then dri...

Embodiment 2~ Embodiment 10

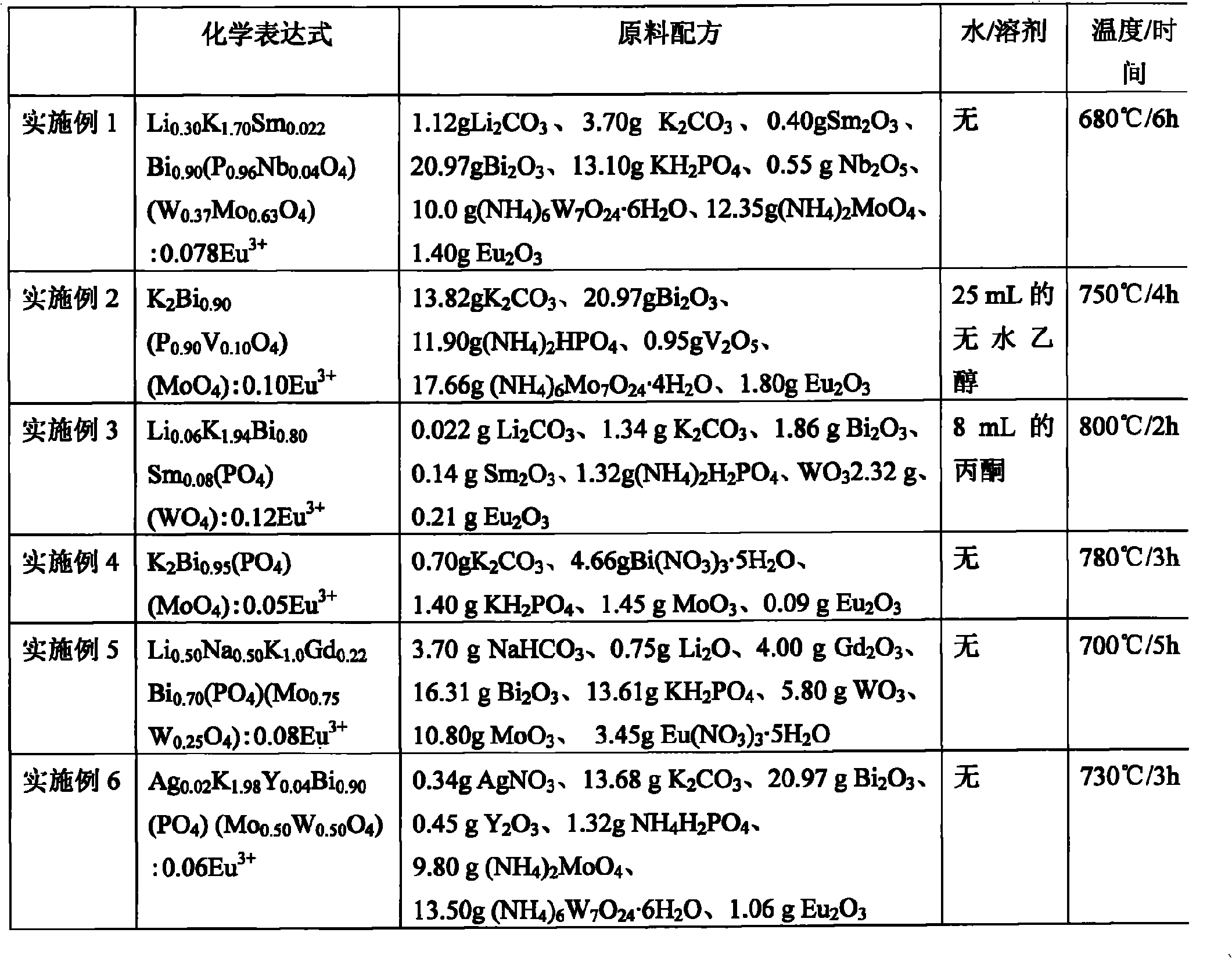

[0025] See Table 1 for the chemical expressions of the red phosphors of Examples 2 to 10. Their preparation methods are basically the same as in Example 1, and the differences are also shown in Table 1.

[0026] Table 1

[0027]

[0028] Connect to Table 1

[0029] Example 7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com