Process for preparing catalyst Pd/TiO2 for hydrogenation of p-carboxybenzaldehyde

A technology of p-carboxybenzaldehyde and hydrogenation process, which is applied in the direction of physical/chemical process catalysts, organic compound preparation, carboxylate preparation, etc. It can solve the problems of poor high-temperature activity of catalysts, lower compressive strength, etc., and achieve conversion rate High, prevent aggregation, improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

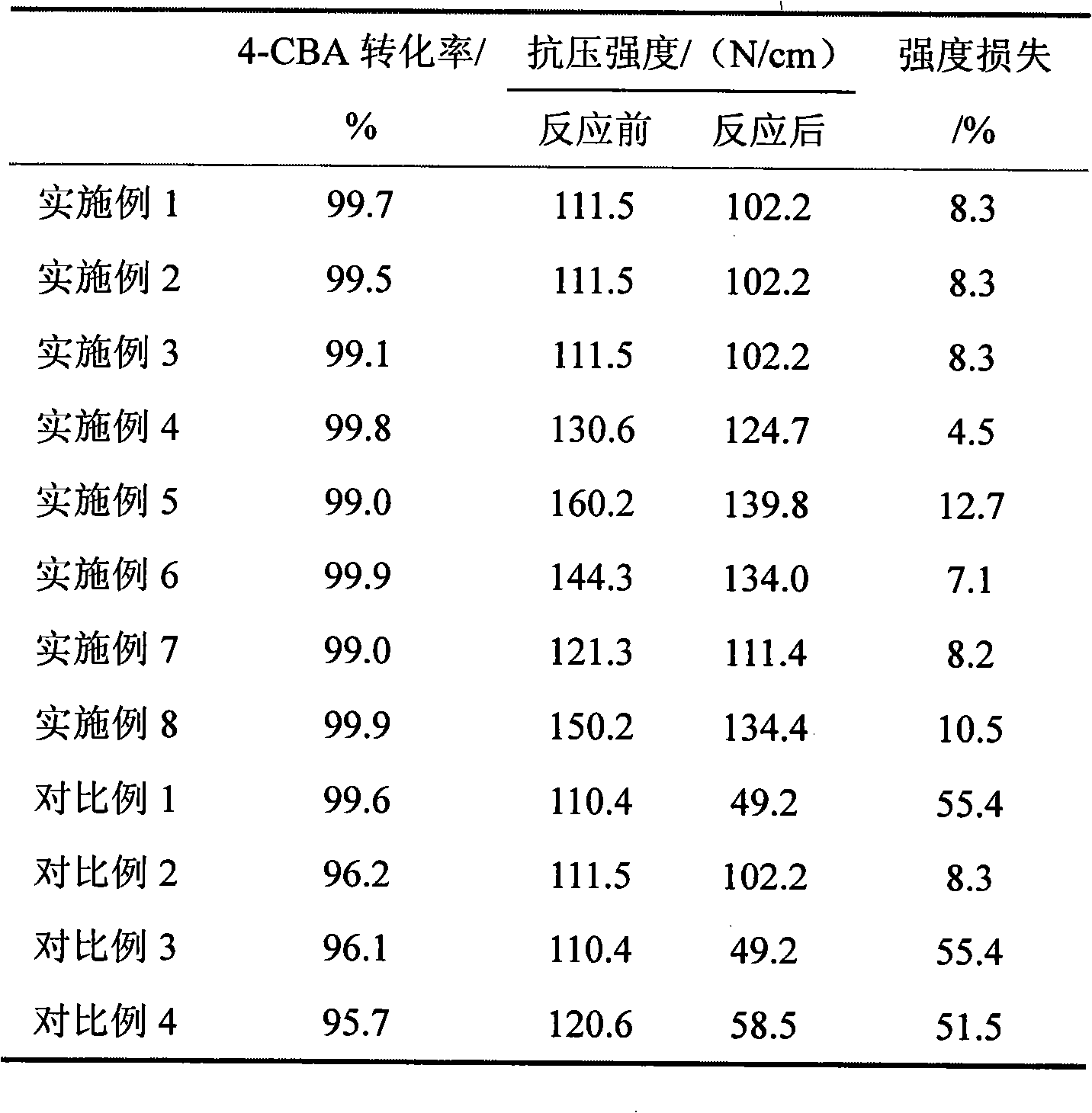

Examples

Embodiment 1

[0032] (1) Add 1 part of ground alkali-free glass fiber to 20 parts of TiO 2 In the powder, mix on a high-speed pulverizer for 30 minutes. Add 1 part of binder methyl cellulose to 10 parts of deionized water at 85°C. After the methyl cellulose swells, cool to room temperature, then add 0.3 parts of peptizing agent nitric acid, and stir evenly to form a gel. Add the resulting gel to the above-mentioned E-glass fiber and TiO 2 In the powder, after kneading on the kneader for 1h, extrude with extruder (extrusion diameter 1.5mm), cut into strips of 5-6mm, and then dry at 100°C for 10h, at 2.5°C / min The heating rate was raised to 700 °C and kept at a constant temperature for 5 hours to prepare ground alkali-free glass fiber doped TiO 2 molding carrier.

[0033] (2) According to the volume ratio of titanium-containing precursor tetrabutyl titanate and absolute ethanol as 1:1, tetrabutyl titanate was added into absolute ethanol, and stirred for 30 minutes to obtain a uniform and t...

Embodiment 2

[0038] According to the volume fraction ratio of the titanium-containing precursor isopropyl titanate and absolute ethanol as 1:3, the isopropyl titanate was added into the absolute ethanol, and stirred for 30 minutes to obtain a uniform and transparent solution. Other steps are the same as in Example 1, making 0.5%Pd / TiO of the present invention 2 catalyst.

Embodiment 3

[0040] According to the volume fraction ratio of the titanium-containing precursor ethyl titanate and absolute ethanol as 1:5, the ethyl titanate was added into the absolute ethanol and stirred for 30 minutes to obtain a uniform and transparent solution. Other steps are the same as in Example 1, making 0.5%Pd / TiO of the present invention 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com