Method for preparing phosphorus-ordered mesoporous carbon complex and fuel-cell catalyst using the complex as carrier

A fuel cell and mesoporous carbon technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of poor mesoscopic structure and achieve controllable morphology , The effect of increasing the pore size and reducing the shrinkage of the mesoscopic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

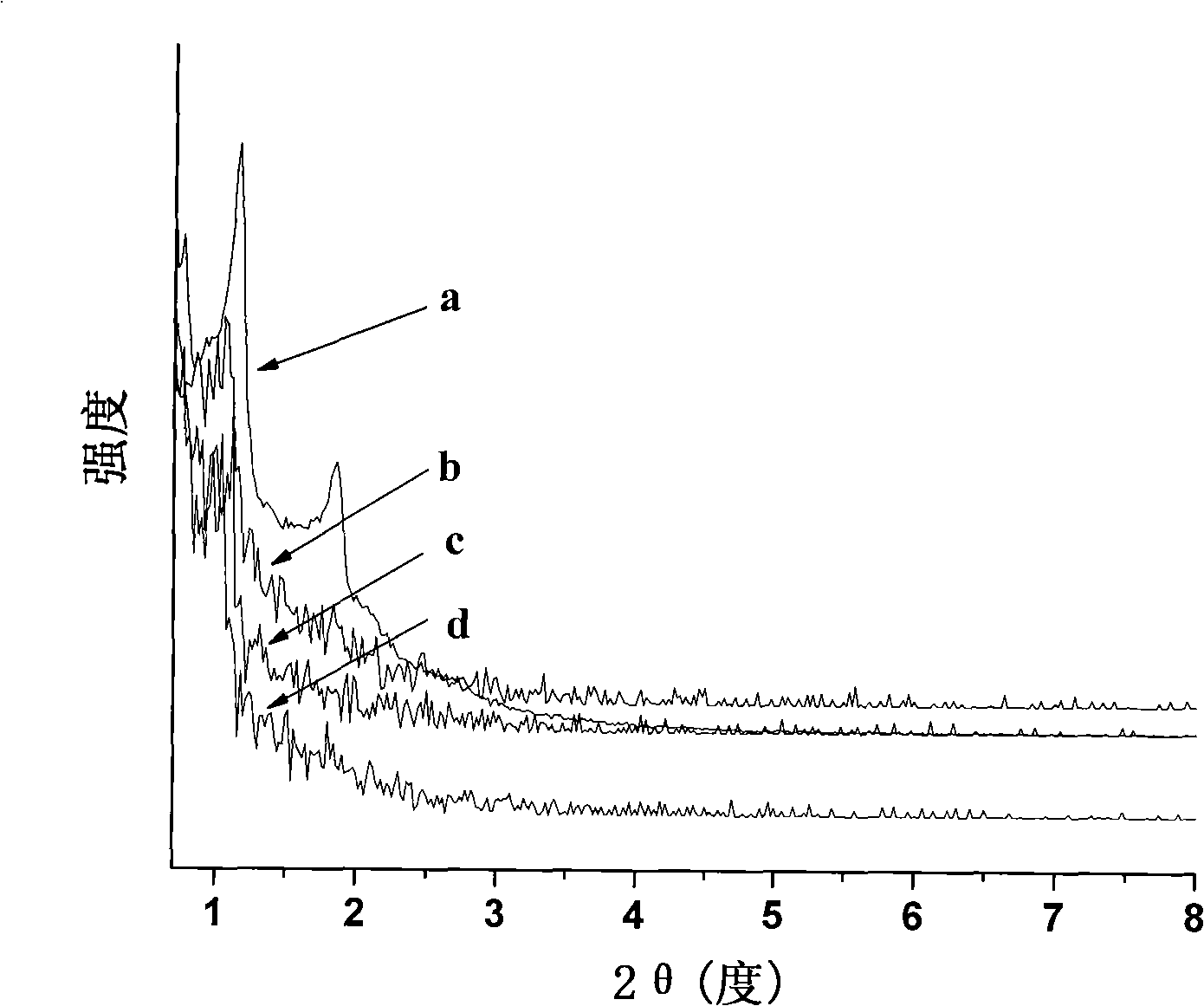

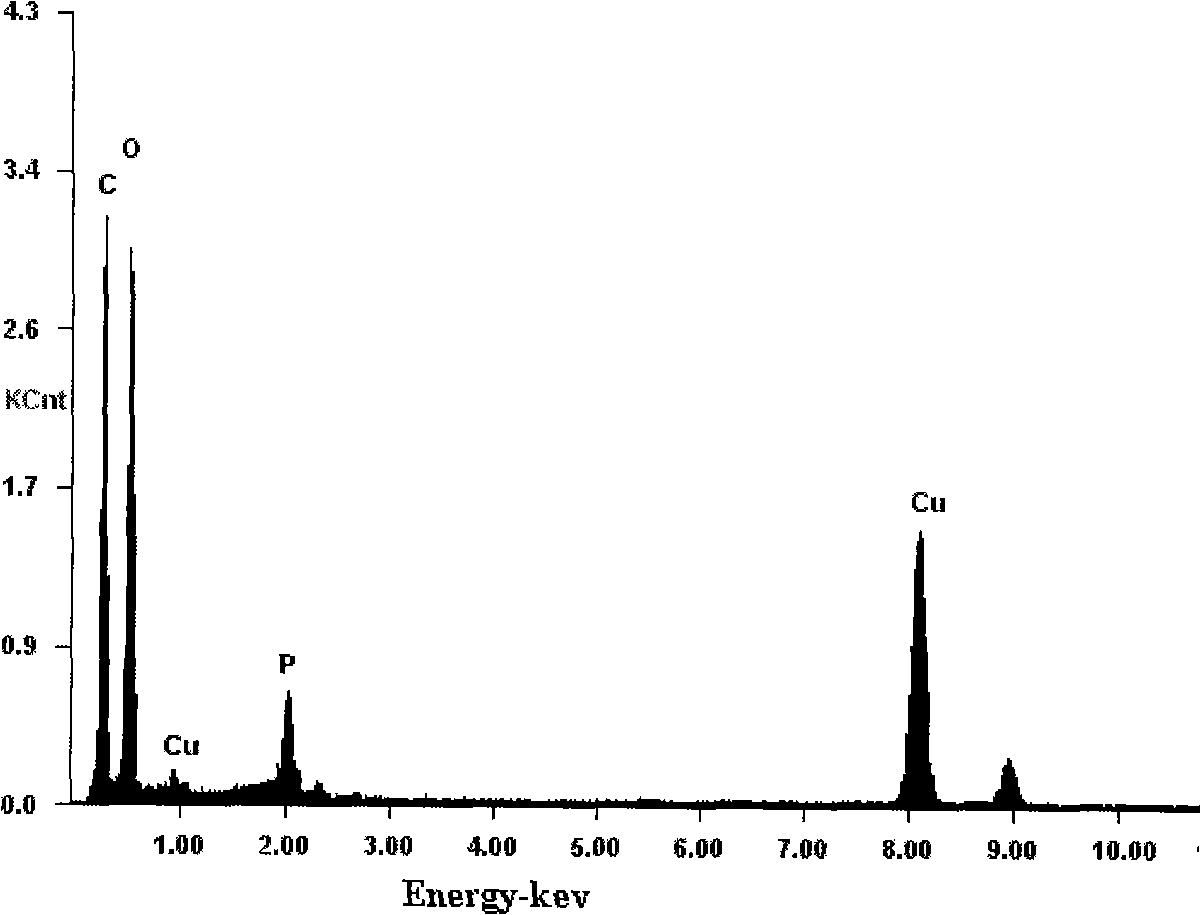

[0024] A preferred embodiment in the synthetic method of P-OMC catalyst carrier, comprises the steps: the inorganic acid containing phosphorus is H 3 PO 4 , the water-soluble resin is formaldehyde phenolic resin, and the ordered mesoporous silica is SBA-15. At room temperature, the SBA-15, H 3 PO 4 Mix with formaldehyde phenolic resin according to the mass ratio (1:0.01:0.5) and then fully stir for 1-5h to react to obtain a milky white solution; vacuum polymerize at 80-120°C for 1-4h; obtain phosphorus-containing dark brown powder in an inert atmosphere The temperature is raised from 30°C to 700°C-900°C at a temperature of 1-3°C / min, roasted for 2-5h, and carbonized at a high temperature in one step to obtain a phosphorus-ordered mesoporous carbon-silicon (P-OMCSi) composite; and then Immerse with 5-20% hydrofluoric acid solution for 10-30h, wash with water until neutral, and dry in vacuum to obtain the P-OMC composite of the present invention.

[0025]A preferred embodime...

Embodiment 1

[0028] Preparation of SBA-15: 4.0g block copolymer P123 (EO 20 PO 70 EO 70 ), 105ml of water, 20ml of hydrochloric acid (37%) and 8.5g of ethyl orthosilicate were mixed, stirred and reacted at 38°C for 2h, then hydrothermally reacted in an oven at 130°C for 24h, and finally roasted at 550°C for 5h in an air atmosphere.

Embodiment 2

[0030] Synthesis of water-soluble resin precursor solution: 8.0g phenol was heated in a 42°C water bath to become transparent, slowly added 14.16g formaldehyde and 0.34g sodium hydroxide (20%) solution, refluxed at 70°C for 60min, cooled to room temperature, and adjusted pH to neutral. Distill under reduced pressure at 45°C, cool to room temperature, and prepare 20% ethanol solution.

[0031] Preparation of catalyst support

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com