Integrated nano inorganic wall light heat insulation facing section bar and preparation thereof

A nano-inorganic, integrated technology, applied in the field of building wall insulation materials, can solve the problems of unsafe construction, easy cracking, falling off, etc., achieve good heat insulation performance, good hydrophobic performance, and eliminate expansion and contraction deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

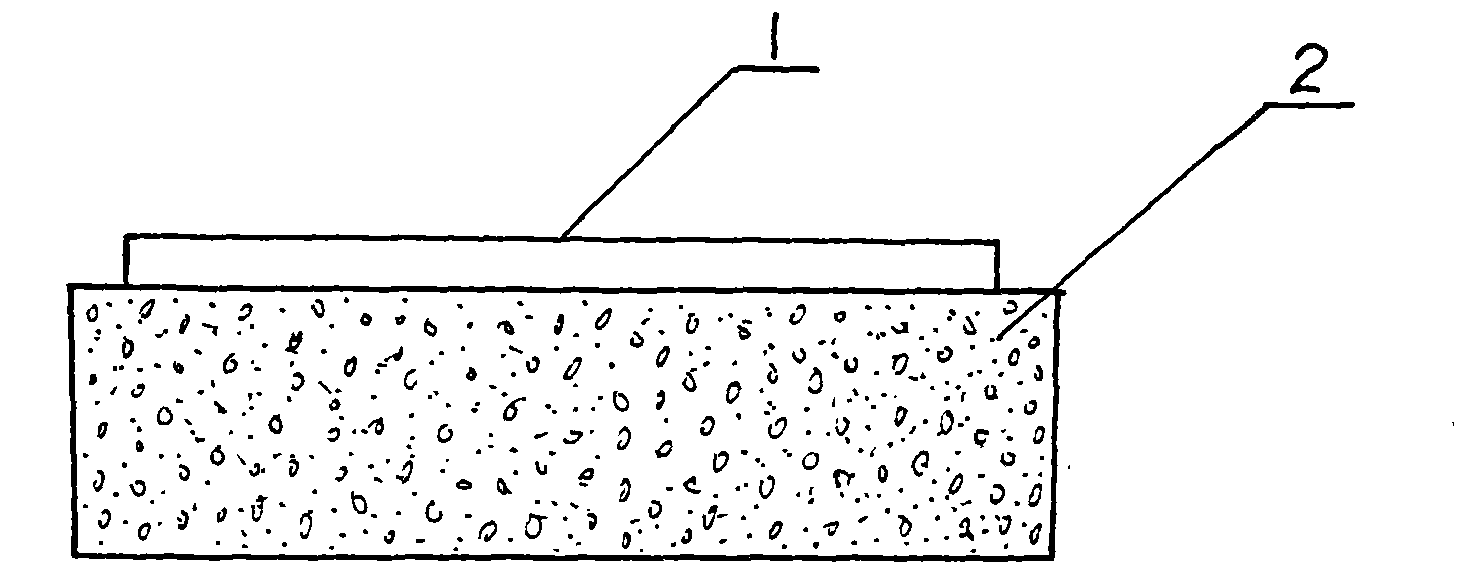

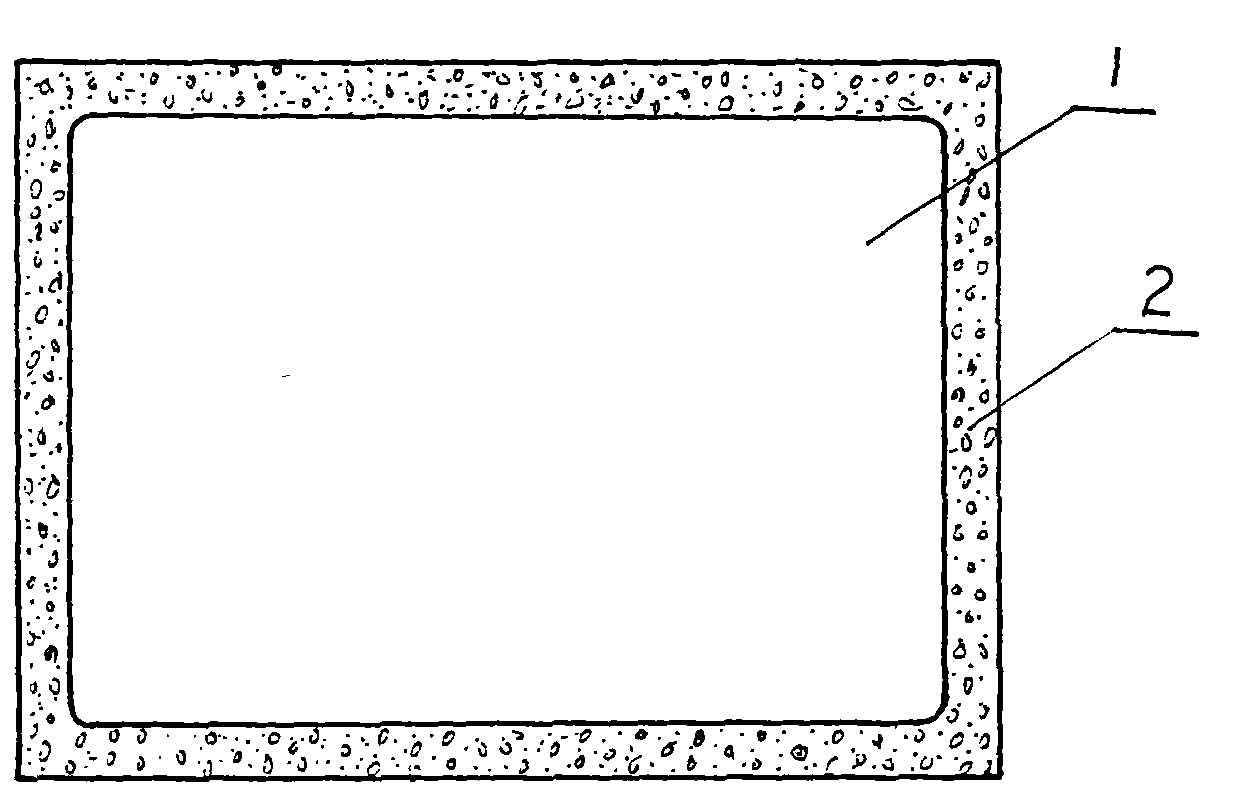

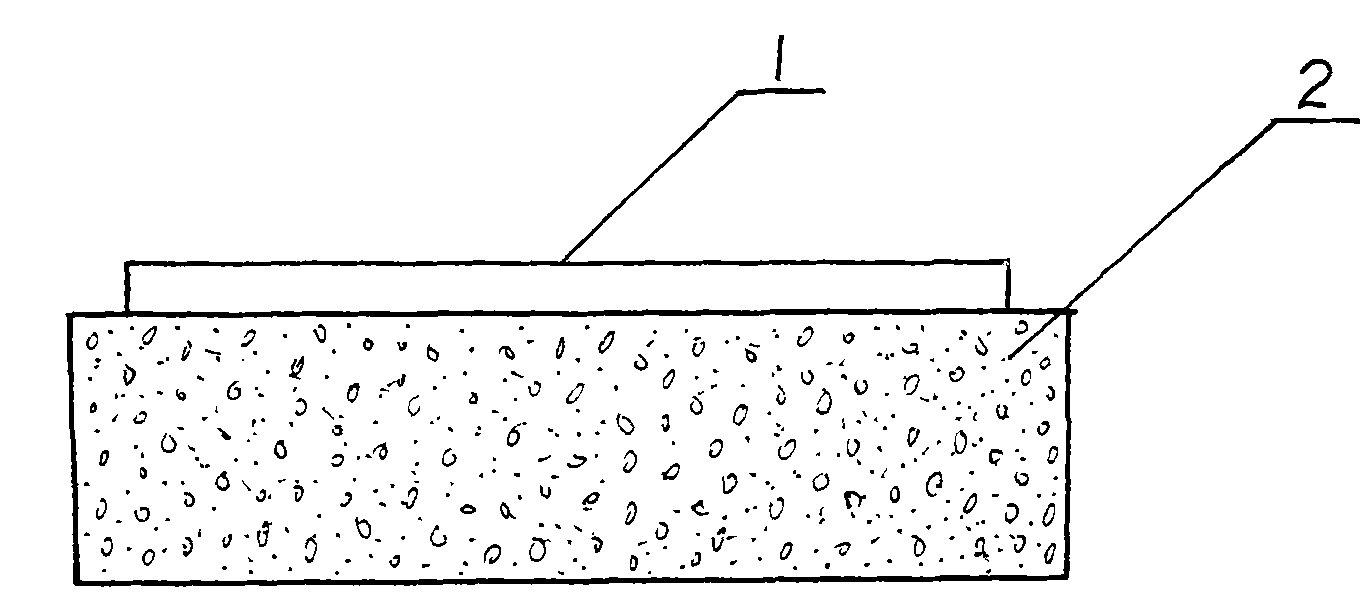

[0033] In the integrated nano-inorganic wall light heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-resisting matrix 2 can be: 50 parts of fruit shell type expanded perlite light aggregate, 8 parts of cement, oxidized 3 parts of silicon micropowder, 3 parts of wood fiber micropowder, 0.5 part of organic silicon emulsion, 1 part of cement reinforcing agent; the weight ratio of each component raw material in the facing layer 1 can be: 40 parts of quartz sand, 8 parts of calcium carbonate, 8 parts of calcium oxide, 8 parts of cement, 3 parts of silicon oxide micropowder, 0.8 part of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix 2 and the finish layer 1 can be: heat preservation matrix: finish layer=100:5 . Wherein the silicon oxide micropowder and wood fiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 50nm.

[00...

Embodiment 2

[0037] In the integrated nano-inorganic wall light-weight heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-insulation matrix 2 can be: 60 parts of fruit shell type expanded perlite light aggregate, 12 parts of cement, oxidized 4 parts of silicon micropowder, 4 parts of wood fiber micropowder, 0.7 part of organic silicon emulsion, 2 parts of cement reinforcing agent; 12 parts of calcium oxide, 12 parts of cement, 4 parts of silica micropowder, 1.0 part of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix and the finish layer can be: heat preservation matrix: finish layer=100:10. Wherein the silicon oxide micropowder and wood fiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 100nm.

[0038] The preparation method of this thermal insulation facing profile is basically the same as that of Example 1, the only difference...

Embodiment 3

[0040] In the integrated nano-inorganic wall light heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-resisting matrix 2 can be: 70 parts of fruit shell type expanded perlite light aggregate, 15 parts of cement, oxidized 5 parts of silicon micropowder, 5 parts of wood fiber micropowder, 0.8 part of organic silicon emulsion, 3 parts of cement reinforcing agent; 15 parts of calcium oxide, 15 parts of cement, 5 parts of silicon oxide micropowder, 1.2 parts of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix 2 and the finish layer 1 can be: heat preservation matrix: finish layer=100:20 . Wherein the silicon oxide micropowder and lignofiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 1000nm.

[0041] The preparation method of this thermal insulation facing profile is basically the same as in Example 1, the only differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com