Orientational alignment carbon nano-tube and carbon coating cobalt nano-particle complex and preparation thereof

A carbon-coated cobalt nanometer and particle composite technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of long reaction time, complex method, difficult application, etc., and achieves high work efficiency, simple operation, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

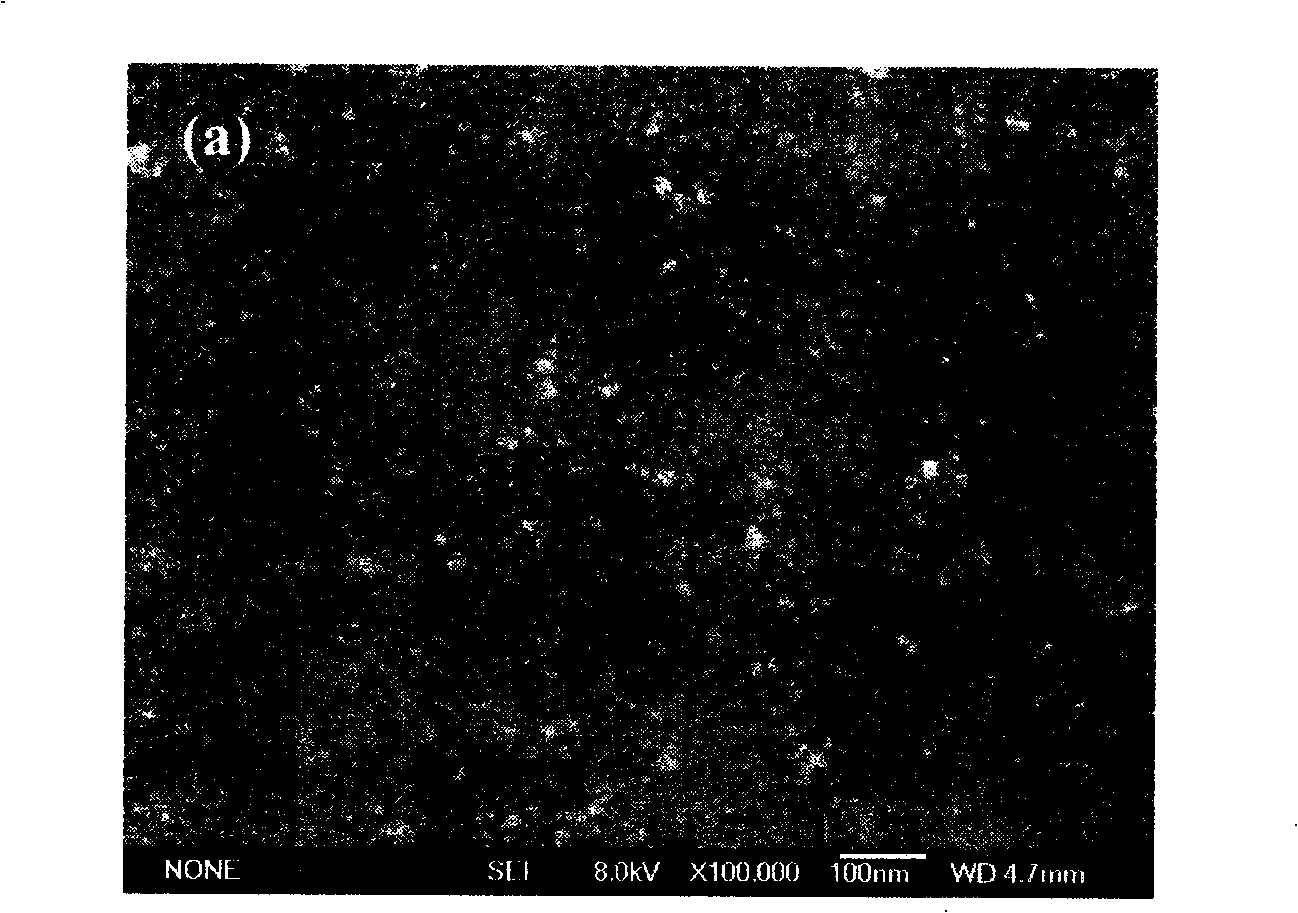

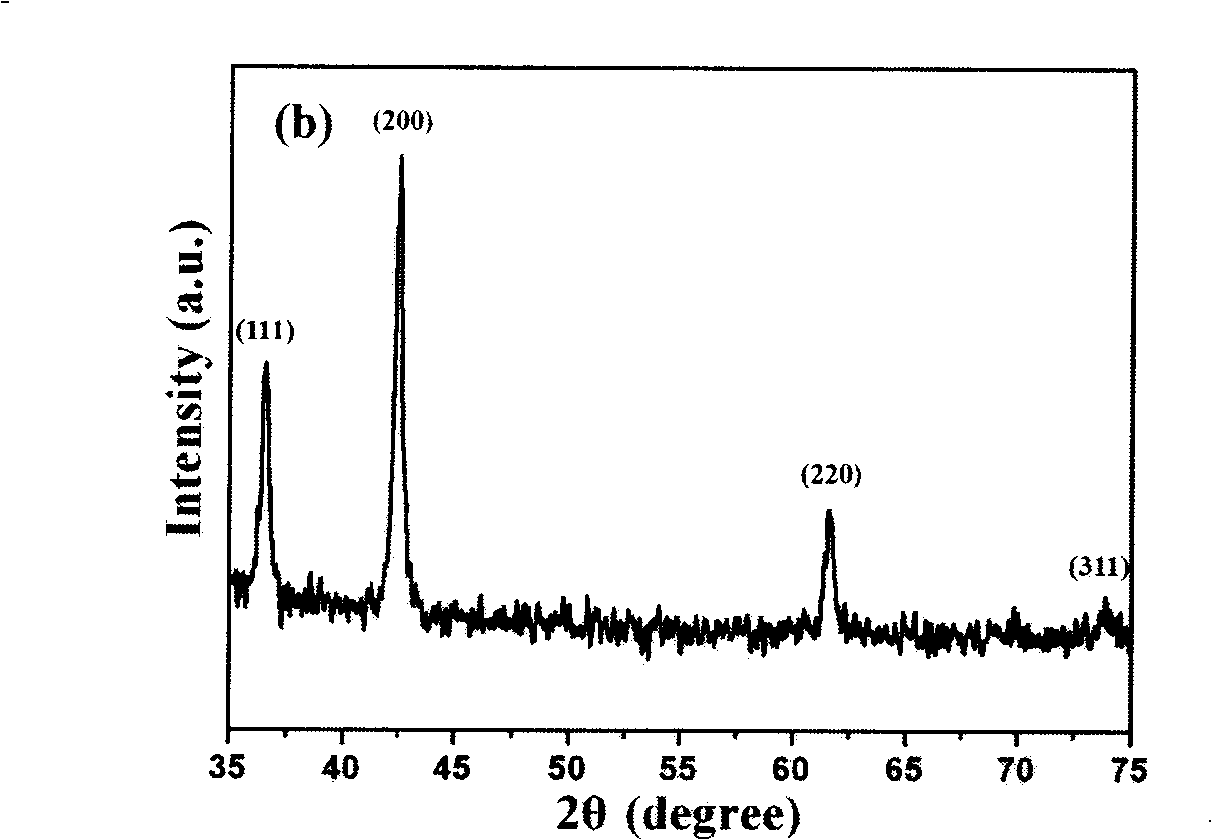

[0029] Example 1: The steps of the preparation method of this embodiment are:

[0030] (1) Using the RF magnetron sputtering method, using Co as the target source and Ar as the discharge gas, the Co film is deposited on the Si substrate. The deposition system is a DPS-III target magnet produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences. Controlled sputtering equipment, DC sputtering current is 0.1A, DC sputtering voltage is 280V, Ar gas flow is 60.2sccm, working pressure is 0.5Pa, and deposition time is 60s.

[0031] (2) Put the Co thin film obtained in step (1) into a plasma enhanced chemical vapor deposition equipment. The deposition system is a JGP300A high-vacuum single-target high-temperature coating equipment produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences, and it is evacuated to 5Pa. Access O 2 The flow rate is 2sccm, the working pressure is 20Pa, and the temperature is in...

Embodiment 2

[0034] Example 2: The preparation method steps of this embodiment are:

[0035] (1) Using the radio frequency magnetron sputtering method, using Co as the target source and Ar as the discharge gas, the Co film is deposited on the Si substrate. The deposition system is a DPS-III target magnet produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences. Controlled sputtering equipment, DC sputtering current is 0.1A, DC sputtering voltage is 280V, Ar gas flow is 60.2sccm, working pressure is 0.5Pa, and deposition time is 60s.

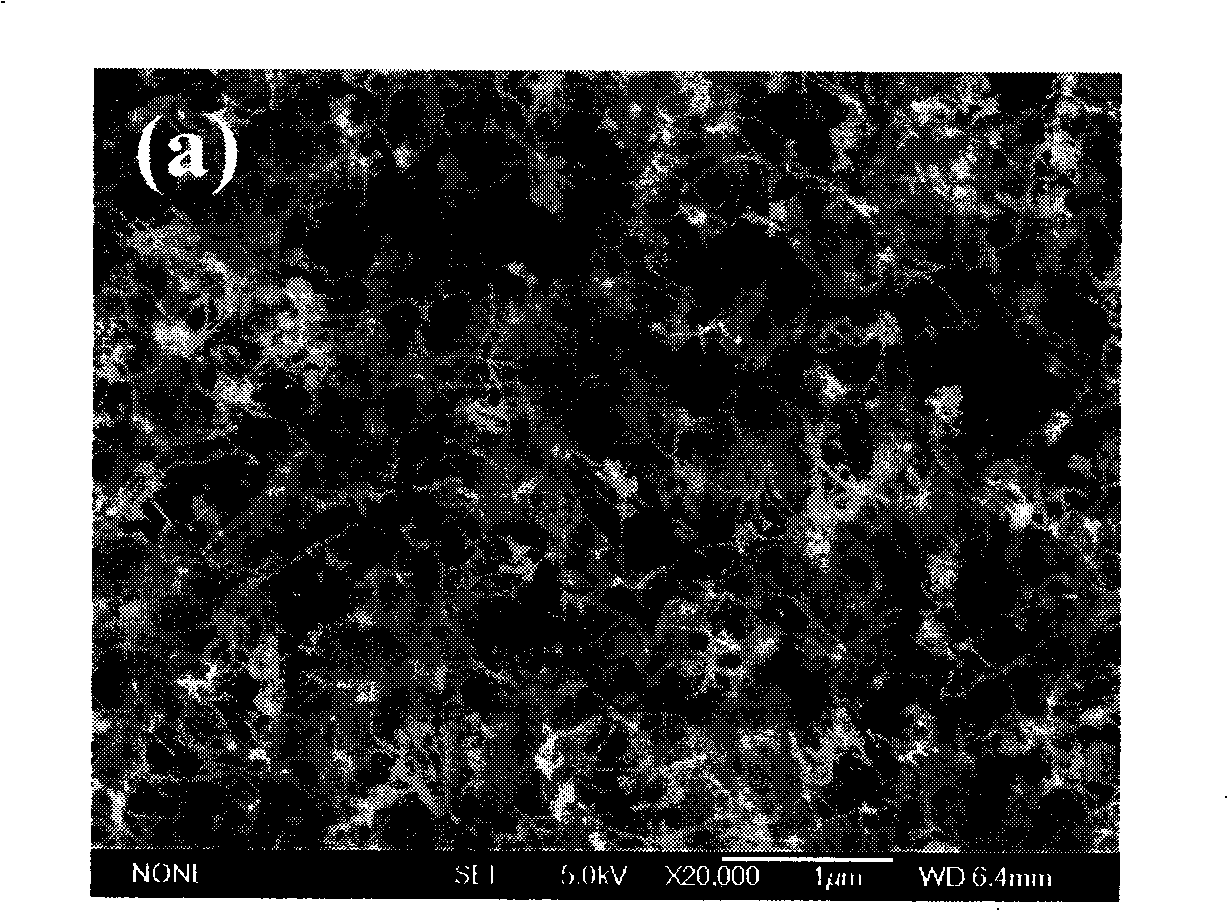

[0036] (2) Put the Co thin film obtained in step (1) into a plasma enhanced chemical vapor deposition equipment. The deposition system is a JGP300A high-vacuum single-target high-temperature coating equipment produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences, and the vacuum is evacuated to 5Pa. Access O 2 The flow rate is 2sccm, the working pressure is 20Pa, and the tempe...

Embodiment 3

[0039] Example 3: The preparation method steps of this embodiment are:

[0040] (1) Using the radio frequency magnetron sputtering method, using Co as the target source and Ar as the discharge gas, the Co film is deposited on the Si substrate. The deposition system is a DPS-III target magnet produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences. Controlled sputtering equipment, DC sputtering current is 0.1A, DC sputtering voltage is 280V, Ar gas flow is 60.2sccm, working pressure is 0.5Pa, and deposition time is 60s.

[0041] (2) Put the Co thin film obtained in step (1) into a plasma enhanced chemical vapor deposition equipment. The deposition system is a JGP300A high-vacuum single-target high-temperature coating equipment produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences, and the vacuum is evacuated to 5Pa. Access O 2 The flow rate is 2sccm, the working pressure is 20Pa, and the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com