Method for preparing nano zinc oxide using shell powder as carrier

A technology of nano-zinc oxide and shell powder, which is applied in the field of nano-materials, can solve the problems of reducing the catalytic activity of ZnO, poor adhesion of titanium dioxide, and limiting wide application, etc., and achieves the effect of small air resistance, strong binding force and improved adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

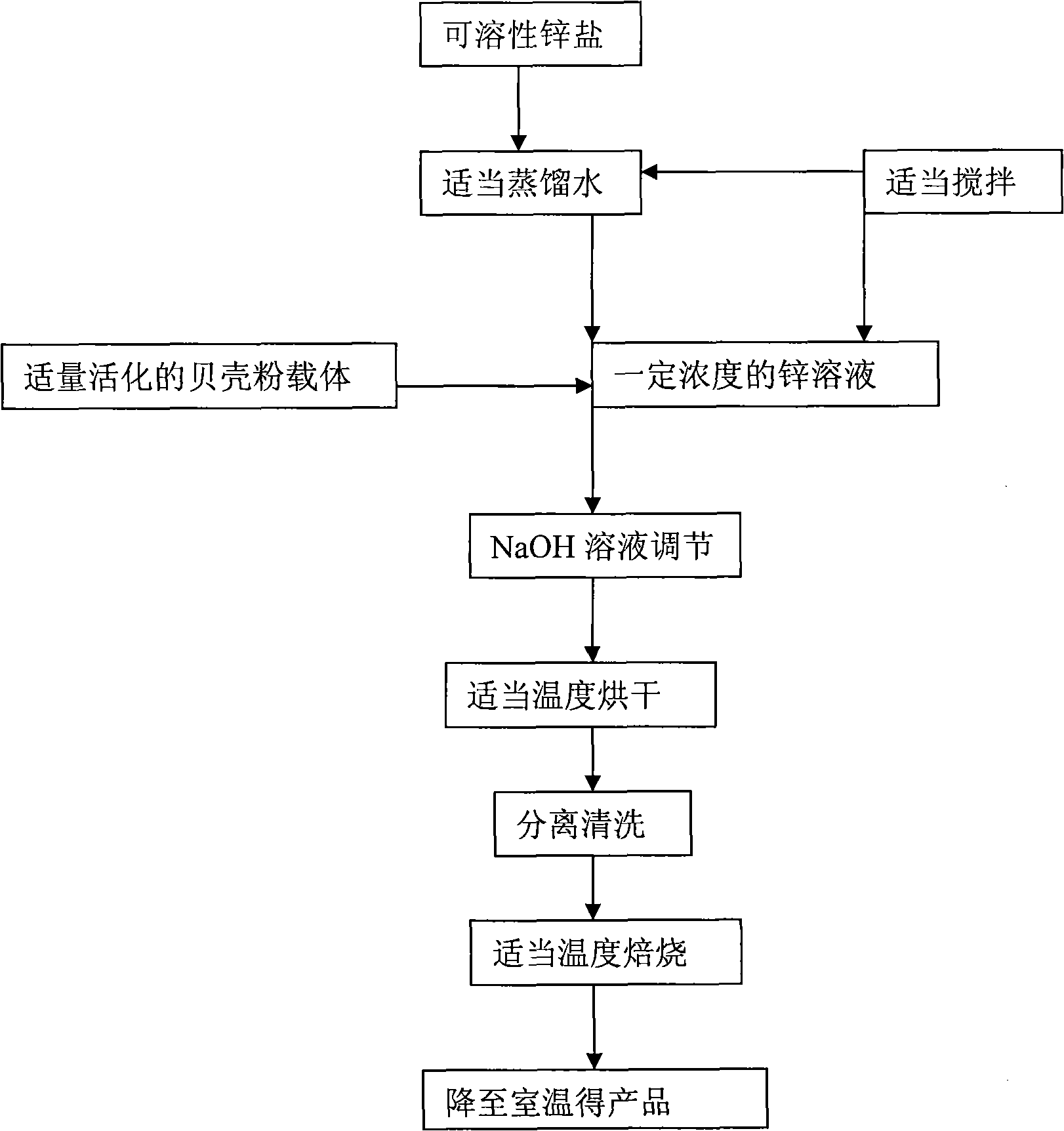

Method used

Image

Examples

Embodiment 1

[0025] At room temperature, add 2g of zinc acetate to 100ml of distilled water, stir for 15min, take 10g of activated oyster shell powder carrier and soak in the solution, adjust the NaOH solution to pH=8, stir for 1h, let stand for 10h, pour off the clear liquid, Dry at 110°C, rinse with distilled water repeatedly to remove weakly bonded ZnO, dry at 70°C, and then bake at 400°C in a horse heart furnace, control the heating rate of 2K / min, after heating to 250°C, keep the temperature constant, Then the temperature is raised to 400° C., and the temperature is kept constant to obtain nano-ZnO immobilized by oyster shell powder, and finally the temperature is lowered to room temperature for use. Multiple impregnations can be performed to increase the loading capacity.

Embodiment 2

[0027] At room temperature, add 3 g of zinc phenolsulfonate to 100 ml of distilled water, stir for 20 min, take 10 g of activated oyster shell powder carrier and soak in the solution, adjust the NaOH solution to pH = 10, stir for 1 h, let stand for 10 h, pour off the clear water solution, dried at 100°C, rinsed repeatedly with distilled water to remove weakly bonded ZnO, dried at 70°C, and then roasted at 450°C in a horse-sand furnace, controlling the heating rate of 1K / min, and after heating to 250°C, Keep the temperature constant, then raise the temperature to 450°C, and then keep the temperature constant to obtain nano-ZnO immobilized by oyster shell powder, and finally cool down to room temperature for use. Multiple impregnations can be performed to increase the loading capacity.

Embodiment 3

[0029] At room temperature, add 3 g of zinc nitrate to 100 ml of distilled water, stir for 10 min, take 15 g of activated oyster shell powder carrier and soak in the solution, adjust the NaOH solution to pH=9, stir for 1 h, let it stand for 20 h, pour off the clear liquid, Dry at 120°C, wash with distilled water repeatedly to remove the weakly bonded ZnO, dry at 70°C, and then bake at 480°C in a horse heart furnace, control the heating rate of 5K / min, after heating to 250°C, keep the temperature constant, Then the temperature is raised to 480° C., and the temperature is kept constant to obtain nano-ZnO immobilized by oyster shell powder, and finally the temperature is lowered to room temperature for use. Multiple impregnations can be performed to increase the loading capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com