A strain of Clostridium acetobutylicum, screening method and use thereof

A technology of Clostridium acetobutylicum and acetone butanol, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of high COD of fermentation waste mash and adverse environmental effects, and achieves low COD and solvent. The effect of high dosage and high butanol ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

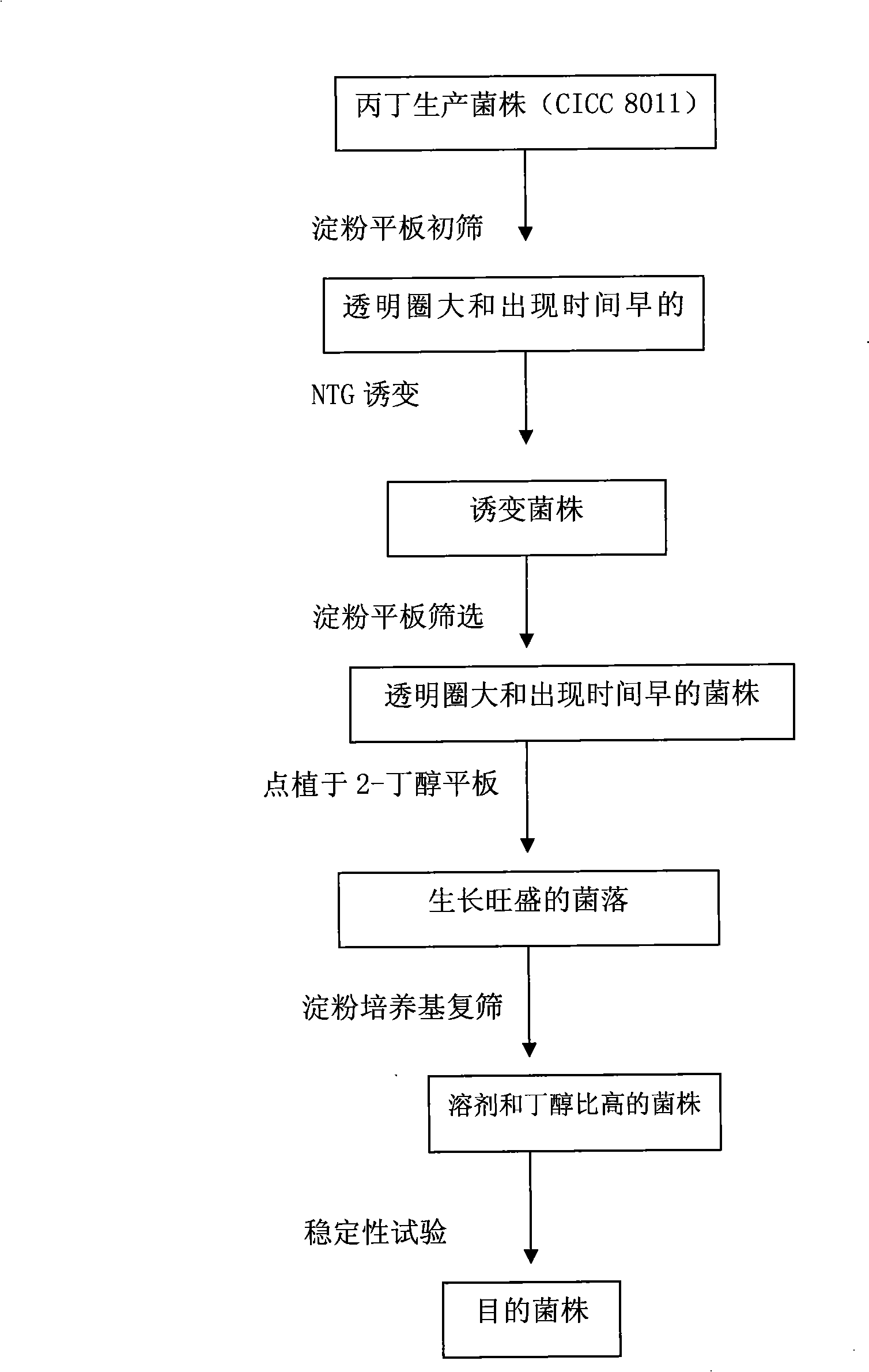

[0038] The determination of embodiment 1 preliminary screening bacterial strain

[0039] The preserved acetobutylicum (CICC 8011) was activated with medium 1 for 40-48 hours to obtain a vigorously growing and robust bacterial liquid. Take the bacterial liquid and spread it evenly on the plate of medium 2, put it upside down in a stainless steel vessel, add an appropriate amount of pyrogallic acid into the vessel, and put it in an incubator at 35-40°C for 3-5 days. After a single bacterium appears on the surface of the plate, select a single colony with a large transparent circle and an early appearance of the transparent circle and insert it into medium 3 for 24-30 hours. Then take the expanded bacterial solution and inoculate it into the newly prepared medium 4 with an inoculum amount of 5-10% for cultivation, and cultivate for 3-5 days, depending on the gas production situation and the total sugar remaining in the fermentation as the judgment index for the end of the ferment...

Embodiment 2

[0043] Example 2: NTG mutagenesis

[0044] The first-screened strains were inserted into medium 3 and cultivated for 24-30 hours. Then take the expanded bacterium liquid and inoculate it into the newly prepared medium 3 according to the inoculum amount of 5-10% and cultivate it for 24-30 hours.

[0045] Take 20ml of the above-mentioned bacterial solution that has been separated and expanded twice by single bacteria, centrifuge at 5000rpm for 10 minutes, and the centrifugation temperature is 2-4°C, pour off the supernatant, add 5ml of phosphate buffer to wash the bacteria, pour into 5ml of nitrous In a test tube of guanidine mutagen (NTG concentration 10-50ug / ml), shake with a constant temperature water bath shaker at 20rpm for 20min, then centrifuge the test tube liquid at 5000rpm for 3 minutes at a centrifugation temperature of 2-4°C, pour off the supernatant liquid and wash it with phosphoric acid. Wash three times with saline buffer.

[0046] 20ug / ml

[0047] ...

Embodiment 3

[0048] Embodiment 3: test tube re-screening

[0049] Starch plate screening

[0050] Draw the NTG-treated and washed bacterial solution according to 10 -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 , and 10-8 dilution times were evenly spread on the plate of medium 2, and placed upside down in a stainless steel vessel, and an appropriate amount of pyrogallic acid was added to the vessel, and placed in an incubator at 35-40°C for 3-5 days , observed regularly every day. After NTG mutagenesis, about 40 or so bacterial strains were obtained, and they appeared early in the transparent circle on the medium 2 plate, and the transparent circle was large.

[0051] Screening of strains with high butanol ratio:

[0052] Use a toothpick to pick out the colony with the fastest time and the largest transparent circle around the bacteria, and plant it on the medium 5 plate containing 1.0-2.5% 2-butanol. Put it in a 35-40°C incubator and culture it for 3-5 days, and observe regularly every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com