Method for preparing nitrogen-containing starch syrup by peeled and degermed maize flour polyzyme method

A technology of starch syrup and corn flour, applied in the direction of fermentation, etc., can solve the problems of difficult storage, waste of oil resources, easy rancidity, etc., and achieve the effects of refining and improving, reducing the formation and quantity of foam, and favorable recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

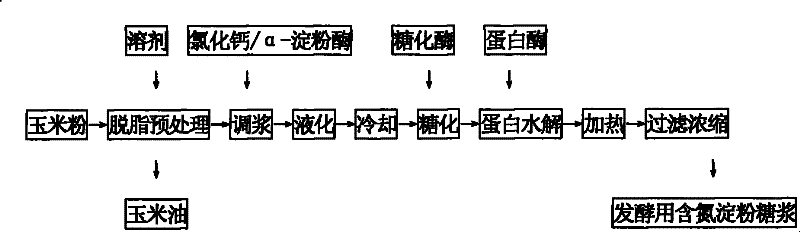

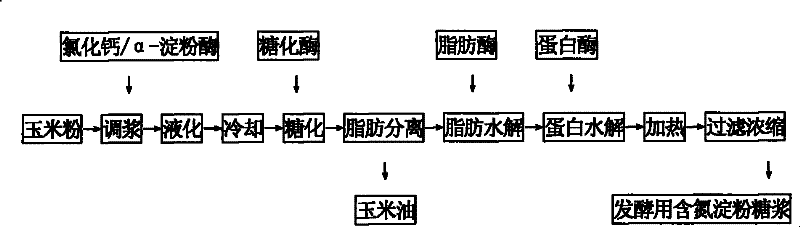

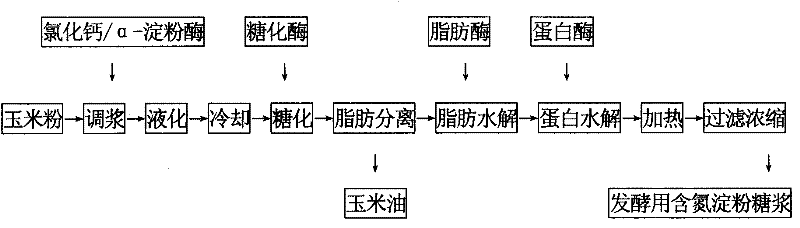

Method used

Image

Examples

Embodiment 1

[0036] (1) Slurry: Add appropriate amount of water to the slurry tank, start stirring, add corn flour, control the concentration of the dry solids of the powder slurry to 25%, add calcium chloride, and control the slurry Ca 2+ The content of Liquozyme Supra high temperature α-amylase at 0.2kg / t is added at the end, and the pH value of the powder slurry is adjusted to 5.6-5.9, and then stirred and mixed evenly.

[0037] (2) Liquefaction: continuous jet liquefaction at 108-110°C, heat preservation treatment of liquefied liquid at 98-100°C for 140 minutes.

[0038] (3) Saccharification: the temperature of the liquefied liquid is lowered to 55-60° C., the pH value is 4.1-4.3, and 0.6 kg / t Dextrozyme DX glucoamylase is added to act for 45 hours to separate the corn oil that floats. Then add 0.02kg / t lipase for hydrolysis, the total hydrolysis time is 70 hours, and the DE value of the product is 97.8.

[0039] (4) Protein conversion: After saccharification, control the temperature ...

Embodiment 2

[0042] (1) Degreasing: extract the fat in the corn flour with a cyclohexane solvent at a certain flow rate in a countercurrent manner, and when the fat content of the corn flour is reduced to less than 0.15%, remove the solvent in the corn flour by vacuum flash evaporation to obtain Raw material for cornmeal production.

[0043] (2) Slurry: Add appropriate amount of water in the slurry tank, start stirring, add corn flour, control the concentration of dry solids in the powder slurry to 45%, add calcium chloride, and control the slurry Ca 2+ The content of 45mg / kg, adjust the pH value of the powder slurry to 6.4, finally add 1.2kg / t of Termamyl 120L high temperature α-amylase, stir and mix evenly.

[0044] (3) Liquefaction: continuous jet liquefaction at 108-110°C, heat preservation treatment of liquefied liquid at 98-100°C for 60 minutes.

[0045] (4) Saccharification: Cool the liquefaction solution to 50-55°C, pH value is 5.6-5.9, add 1.5kg / t β-amylase, hydrolyze for 10 hour...

Embodiment 3

[0049] (1) Slurry: Add appropriate amount of water to the slurry tank, start stirring, add corn flour, control the concentration of dry solids in the slurry to about 35%, add calcium chloride, and control the Ca of the slurry 2+ content of 40mg / kg, adjust the pH value of the powder slurry to 6.0-6.2, and finally add 0.8kg / t of Suhong AA Plus high-temperature α-amylase, stir and mix evenly.

[0050] (2) Liquefaction: Continuous jet liquefaction at 108-110°C, heat preservation treatment of liquefied liquid at 95-98°C for 140 minutes.

[0051] (3) Saccharification: Cool the liquefied liquid to 54-58°C, pH value is 4.1-4.4, add 1.0kg / t SuhongGA II or Dextrozyme GA glucose glucoamylase for saccharification for 50 hours, separate corn oil, then add 0.01kg / t The Finizym W lysophospholipase was hydrolyzed, and hydrolyzed for 15 hours, and the DE value of the product was 98.2.

[0052] (4) Protein conversion: the material temperature is 56-50°C, the pH value is 6.5-7.0, add 0.005kg / t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com