Catalyst for exhaust gas purification and exhaust gas purification catalyst member

A technology of exhaust purification and catalyst, which is applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of not saving precious metals and unfavorable costs, and achieve low cost, saving precious metals, High temperature durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

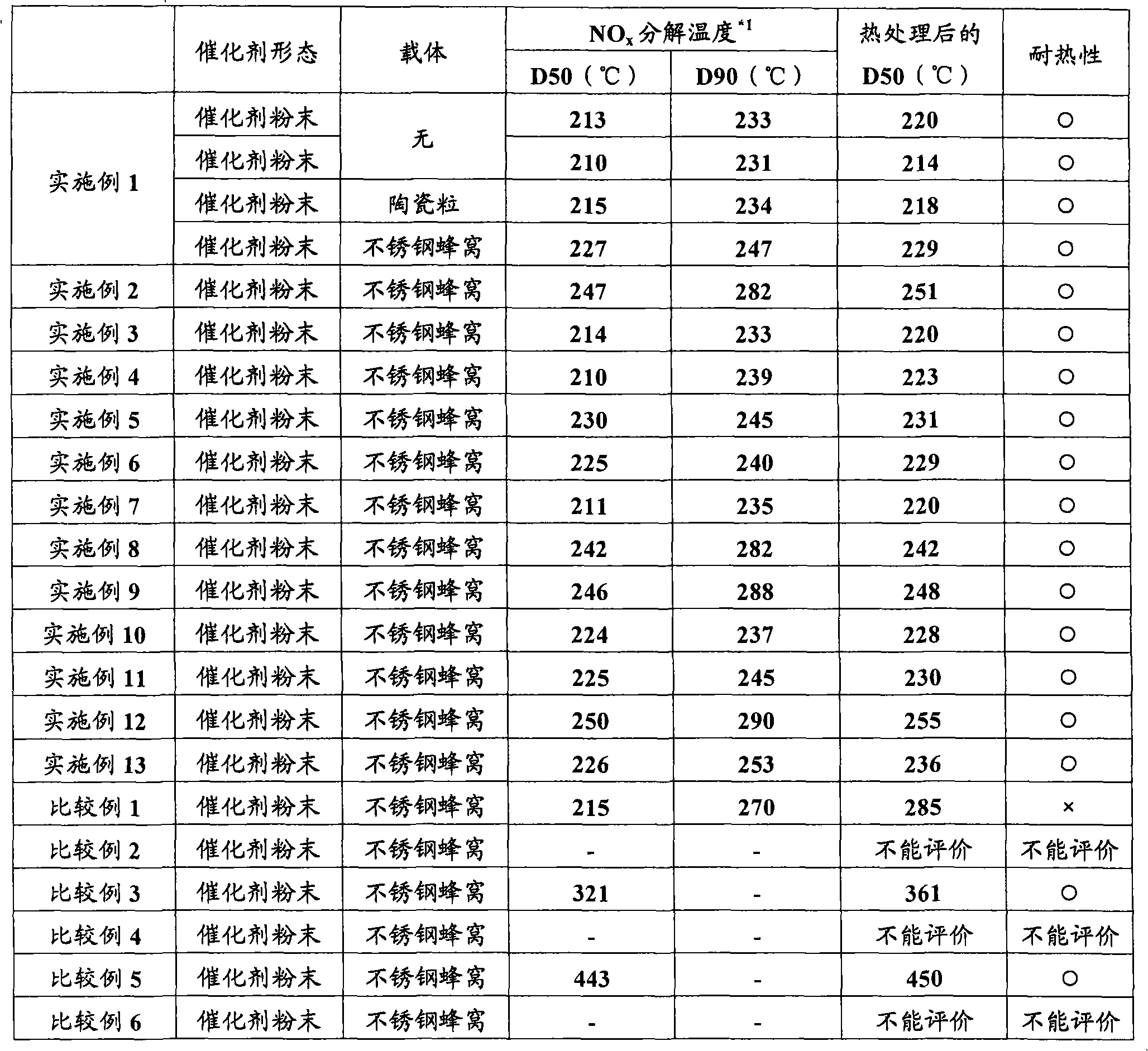

Embodiment 1

[0074] Manufactured with B 0.2 Sr 0.8 co 0.9 Nb 0.1 o 3-δ The composition of the perovskite-type oxide-supported Pd catalyst and the catalyst member using the catalyst were evaluated for catalytic performance.

[0075] Ba 0.2 Sr 0.8 co 0.9 Nb 0.1 o 3-δ Manufactured by the following method.

[0076] Granular BaCO is used as raw materials for Ba, Sr, Co and Nb 3 , SrCO 3 、Co 3 o 4 and Nb 2 o 5 . The raw materials were weighed so that the molar ratio was Ba:Sr:Co:Nb=0.2:0.8:0.9:0.1, added to isopropanol (dispersion medium), and wet-mixed while pulverizing with a ball mill to obtain a slurry. The solids were separated from the slurry using a suction filter and dried at about 120° C. for 1 hour. Next, the obtained dry solid was crushed, put into a polygon or container made of Mgo ceramics, and fired at 1050° C. in the air for 5 hours using an electric furnace to obtain a porous block-shaped fired product. After crushing the burnt product, use an automatic mortar t...

Embodiment 2

[0086] Manufactured with Ba 0.7 Sr 0.3 Fe 0.9 Nb 0.1 o 3-δ The perovskite-type oxide of the composition supported catalyst powder of 0.6 mass % of Pd and 0.1 mass % of Ag, and the catalyst powder was used to manufacture a catalyst member, and the catalytic performance was evaluated.

[0087] Ba 0.7 Sr 0.3 Fe 0.9 Nb 0.1 o 3-δ It was produced by the same method as in Example 1. Here, Fe is used as the Fe-containing raw material 3 o 4 , using powder X-ray diffractometry to analyze the crystal structure of the obtained oxides, only a clear diffraction pattern showing the cubic perovskite type was obtained.

[0088] Next, in the same manner as in Example 1, the above-mentioned Ba 0.7 Sr 0.3 Fe 0.9 Nb 0.1 o 3-δ Pd and Ag were supported to prepare Ba with a Pd loading rate of 0.6 mass % and an Ag loading rate of 0.1 mass %. 0.7 Sr 0.3 Fe 0.9 Nb 0.1 o 3-δ catalyst. Here, as an Ag-containing reagent, commercially available silver nitrate was used as an aqueous sol...

Embodiment 3

[0092] Manufactured with Ba 0.4 Sr 0.6 co 0.9 Nb 0.1 o 3-δ A catalyst in which 0.2% by mass of Pt, 0.6% by mass of Pd, and 0.2% by mass of Rh were supported on a perovskite-type oxide of the composition was used to manufacture a catalyst member, and the catalytic performance was evaluated.

[0093] Ba 0.4 Sr 0.6 co 0.9 Nb 0.1 o 3-δ , adopt the same method as Example 1 to manufacture. Analysis of the crystal structure of the resulting oxide by powder X-ray diffraction revealed only a clear diffraction pattern showing a cubic perovskite type.

[0094] Then, using the same method as in Example 1, the above Ba 0.4 Sr 0.6 co 0.9 Nb 0.1 o 3-δ , loaded Pt, Pd and Rh, obtained Pt loading rate 0.2 mass %, Pd loading rate 0.6 mass %, Rh loading rate 0.2 mass % loaded Pt-Pt-Rh Ba 0.4 Sr 0.6 co 0.9 Nb 0.1 o 3-δ catalyst powder. Here, a commercially available chloroplatinic acid aqueous solution was used as the Pt-containing reagent. In addition, as the Rh-containing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com