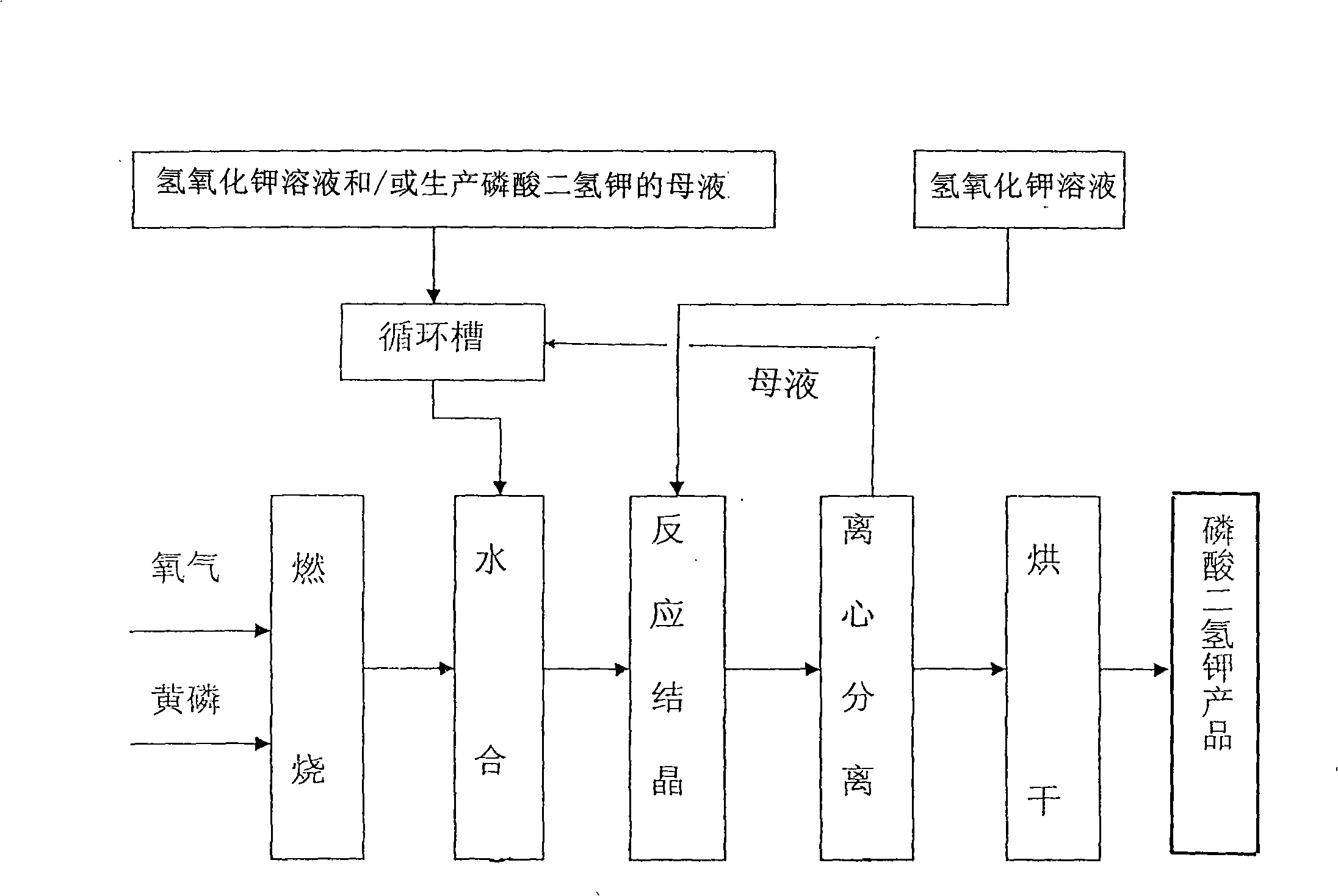

Production process of potassium dihydrogen phosphate

A technology of potassium dihydrogen phosphate and its production method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high energy consumption, achieve the effects of saving resources, reducing production costs, and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 1500kg of potassium hydroxide solution (KOH: 30%) in the circulation tank, and send it into the hydration tower with a circulation pump to spray and absorb the phosphorus pentoxide gas generated by the combustion of yellow phosphorus. The flow of yellow phosphorus is controlled at 150kg per hour. The medium vacuum degree is controlled at 66.64×10 3 pa, adjust the flow of cooling water, the temperature in the hydration tower is controlled at 85°C, after 3 hours of circulating absorption, the density of the mixture of phosphoric acid and potassium dihydrogen phosphate in the circulating tank reaches 1.62×10 3 kg / m 3 , send this mixture into reaction crystallizer with circulation pump again, add potassium hydroxide solution 1220kg (KOH: 30%) again, and control adding speed, make temperature keep on 80 ℃, record density 1.45×10 3 kg / m 3 , PH value 4.5, after cooling, crystallization, centrifugal separation, the mother liquor returns to the circulation tank to be used ...

Embodiment 2

[0027] The mother liquor centrifugally separated in the embodiment one is returned to the circulation tank, sent into the hydration tower with a circulation pump to spray and absorb the phosphorus pentoxide gas generated by the combustion of yellow phosphorus, the flow of yellow phosphorus is controlled at 120kg per hour, and the vacuum degree in the hydration tower controlled at 66.64×10 3 pa, adjust the flow of cooling water, the temperature in the hydration tower is controlled at 95°C, after 2.0 hours of circulating absorption, the density of the mixture of phosphoric acid and potassium dihydrogen phosphate in the circulating tank reaches 1.68×10 3 kg / m 3 , send this mixture into reaction crystallizer with circulation pump again, add potassium hydroxide solution 1420kg (KOH: 30%) again, and control adding speed, make temperature keep on 85 ℃, record density 1.48×10 3 kg / m 3 , PH value 4.6, after cooling, crystallization, centrifugation, the mother liquor returns to the ci...

Embodiment 3

[0031] The centrifuged mother liquor in Example 2 is returned to the circulation tank, and then 900 kg of potassium hydroxide solution (KOH: 30%) is added, and the phosphorus pentoxide gas generated by spraying and absorbing the yellow phosphorus combustion in the hydration tower is sent to the yellow phosphorus with a circulation pump. The flow rate is controlled at 150kg per hour, and the vacuum degree in the hydration tower is controlled at 84.0×10 3 pa, adjust the flow of cooling water, the temperature in the hydration tower is controlled at 90°C, after 2.5 hours of circulating absorption, the density of the mixture of phosphoric acid and potassium dihydrogen phosphate in the circulating tank reaches 1.66×10 3 kg / m 3 , send this mixture into reaction crystallizer with circulation pump again, add potassium hydroxide solution 1330kg (KOH: 30%) again, and control adding speed, make temperature keep on 80 ℃, record density 1.48 * 10 3 kg / m 3 , PH value 4.6, after cooling and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com