High pure graphitic profile and preparation technique thereof

A high-purity graphite and production process technology, applied in the field of graphite material production, can solve the problems of insufficient purity and low density of large-scale products, and achieve the effects of small friction coefficient, high density and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

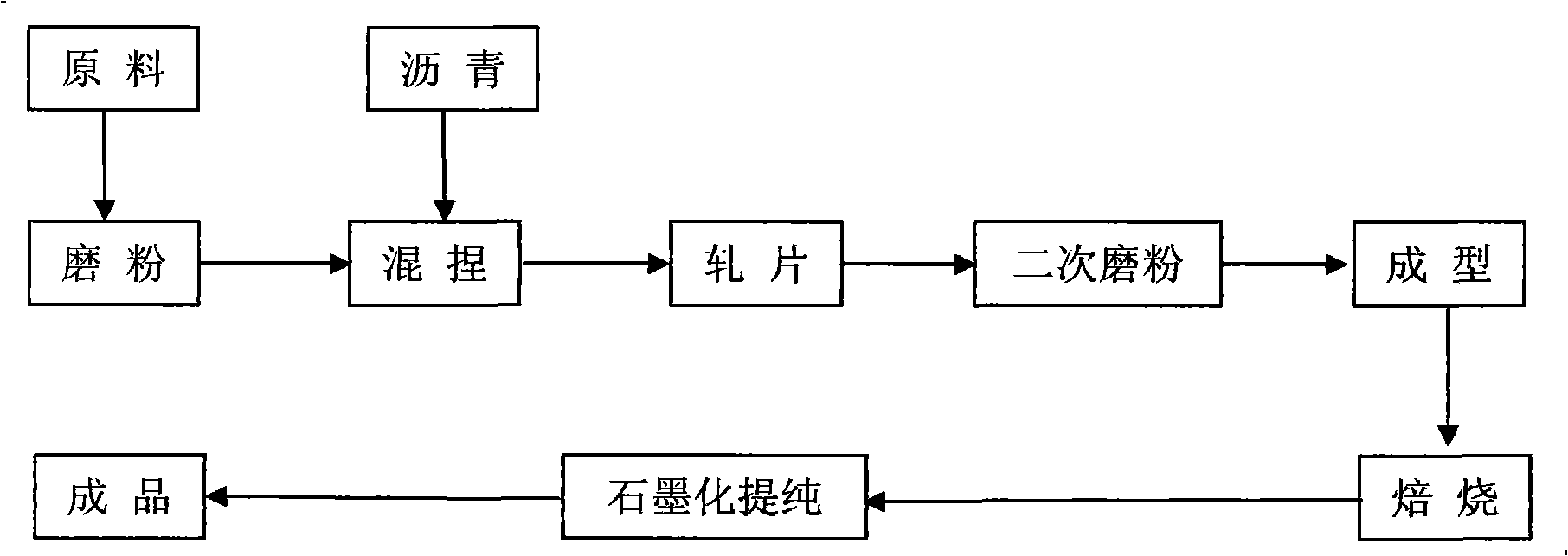

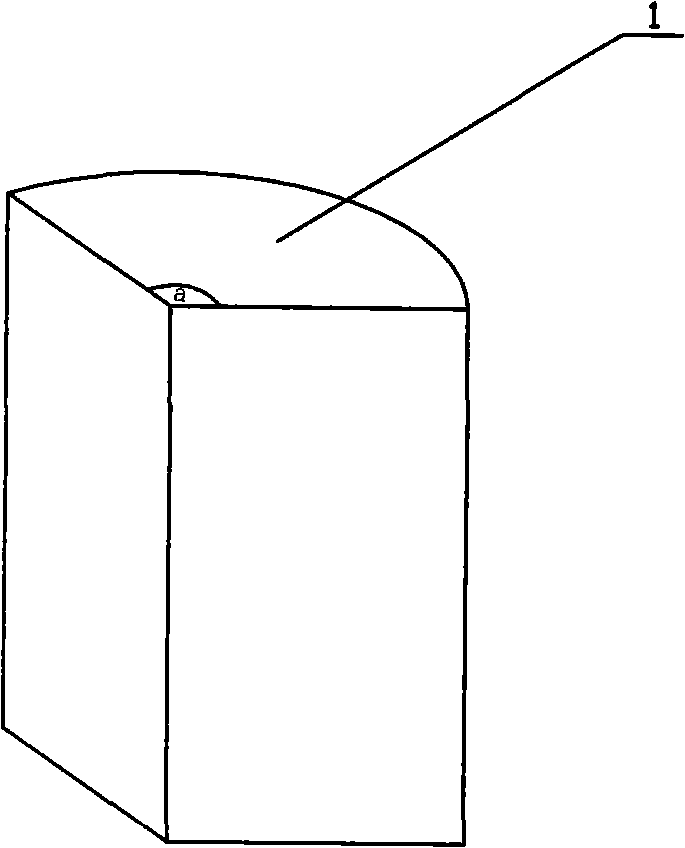

[0039] Example 1 see figure 1 , a production process of high-purity graphite profiles, comprising the following steps:

[0040] (1) Grinding Select calcined petroleum coke (true specific gravity ≥ 2.08g / cm 3 , ash, sulfur, and volatile matter are all ≤0.3%) crushed and milled, with a particle size of 300 mesh;

[0041] (2) Kneading is based on parts by weight. Take 70 parts of the above-mentioned sieved powder and dry mix it in a kneading pot for 50 minutes to reach 130°C; then add 30 parts of molten coal tar pitch (softening point 88 ±2°C), then wet mix in the pot for 70 minutes to reach 155°C;

[0042] (3) Sheet rolling After kneading, the thickness of the sheet rolling for the first time is 2mm, and the thickness of the sheet rolling for the second time is 1.5mm;

[0043] (4) Secondary milling: Carry out secondary milling to 200 orders after the rolled flakes obtained in the previous step are pulverized;

[0044] (5) Compression molding: mold the powder obtained in the ...

Embodiment 2

[0050] Example 2 see figure 1 , the production process steps of a high-purity graphite profile are as follows:

[0051] ① Grinding Select pitch coke for crushing and grinding, and its particle size is 250 mesh;

[0052] ② Kneading Take 75 parts of pitch coke powder after sieving, put it in a kneading pot and dry mix it for 45 minutes to reach 125°C; then add 25 parts of melted coal tar pitch at a temperature of 160°C, and then wet mix it in the pot for 65 minutes, reach 155°C;

[0053] ③Rolled sheet After kneading, the thickness of the first rolled sheet is 3mm, and the thickness of the second rolled sheet is 1.2mm;

[0054] ④Secondary milling The rolled sheet is milled again to 200 mesh;

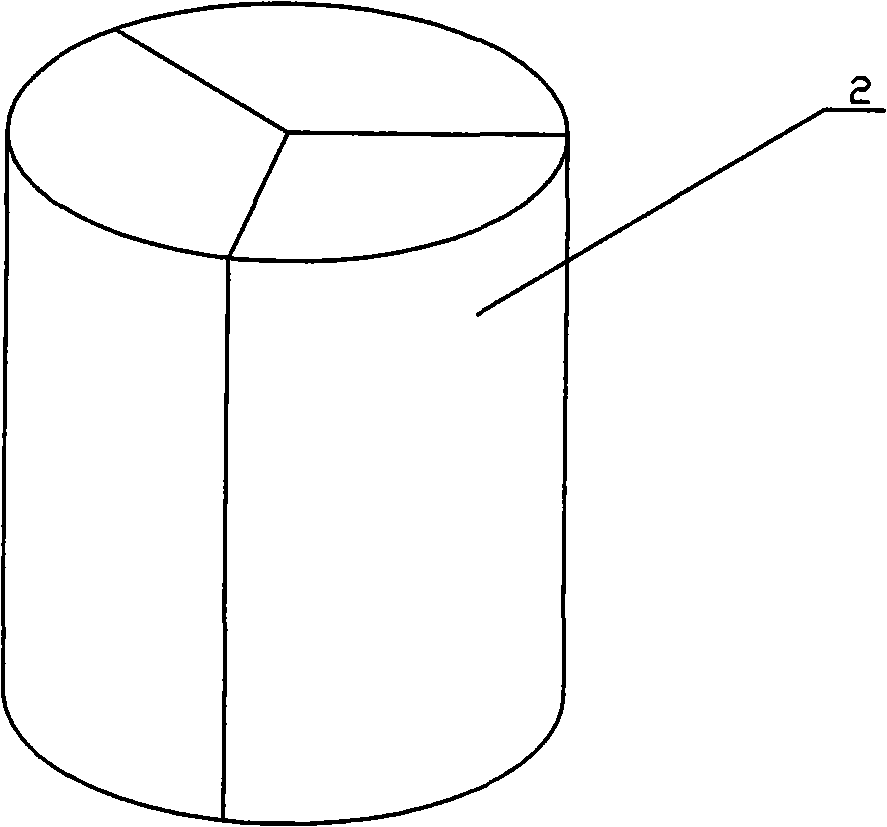

[0055] ⑤ Compression molding: Mold the secondary powder into a specific fan-shaped column;

[0056] ⑥Roasting Put the formed carbon block in a fixed pot, send it into a roasting furnace, slowly raise the temperature from room temperature to 1200°C, and roast for 400 hours;

[0057] ⑦Im...

Embodiment 3

[0062] Embodiment 3 A kind of production technology of high-purity graphite section bar is basically the same as embodiment 1, and difference is: in step (1) with the mixed raw material pulverization of calcined petroleum coke and pitch coke; In step (2) ) used binder is phenolic resin; In step (5), carbon powder is packed into fan-shaped mold, molded into a fan-shaped column with a central angle of section of 72 °; In step (8), one impregnation and two corresponding Roasting; in step (9), the fan-shaped columnar graphite after the roasting is placed in a closed graphite purification electric furnace, and the bottom of the furnace is lined with carbon black, the inner wall of the furnace is lined with pitch coke powder, and the carbon products are filled with calcined coke particles The gap between them; the inner chamber of the purification furnace is purged with nitrogen, and the temperature is raised to 2200°C within 52 hours, and the chlorine gas is passed through at a flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com