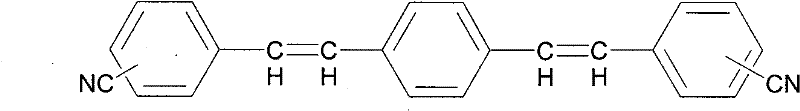

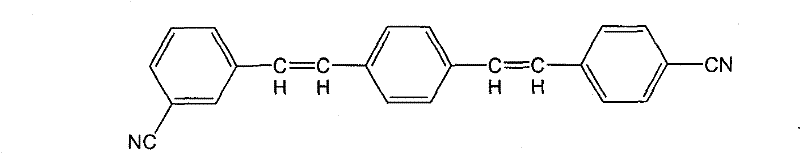

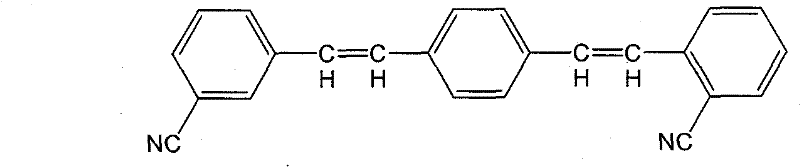

Method for preparing dicyano-1,4phenylethenes asymmetric fluorescent whitener

A technology of fluorescent whitening agent and stilbene, which is used as an auxiliary agent in the fiber industry and in the field of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of cyanobenzyl phosphate

[0036] Under normal pressure, add 54.8g of triethyl phosphite into a 250mL four-neck bottle with a condensing device, stir mechanically, raise the temperature to about 120°C, dissolve 50g of m-cyanobenzyl chloride in 100mL of benzene and place it under constant pressure The liquid funnel was added dropwise to the reactor within 1 hour, and the benzene was continuously distilled out at the same time. After the feeding was completed, the temperature was raised to 150°C and kept for 3 hours. The reaction liquid was detected by gas chromatography, and the reaction was basically complete. The ester is 73.1g, the yield is 95.1%, and the effective content is above 98%.

[0037] When the raw material is o-cyanobenzyl chloride, the above method is used to prepare o-cyanobenzyl phosphate; when the raw material is p-cyanobenzyl chloride, the above method is used to obtain p-cyanobenzyl phosphate.

Embodiment 2

[0038] Embodiment 2: the preparation of fluorescent whitening agent ER (m / p)

[0039] Add 13.4g of terephthalaldehyde and 80mL of DMF into a 250mL three-neck flask, and add dropwise the methanol solution of 25.3g of p-cyanobenzyl phosphate and 19.3g of sodium methoxide in a constant pressure dropping funnel within 1 hour (mass percentage content 28%-30%), the temperature is controlled between 10~15 ℃, after dripping, keep warm at 20 ℃~30 ℃ for 2 hours; then add 25.3g m-cyanobenzyl phosphate and 3.3g hard Calcium fatty acid, add 19.3g of sodium methoxide solution dropwise within 1 hour (the content is the same as above), the temperature is controlled between 20°C and 30°C, and the temperature is kept at 45°C to 50°C for 2 hours after dropping. The reaction solution was beaten with 20mL of methanol, filtered under reduced pressure, washed with 20mL of methanol and 20mL of water in turn, and then dried to obtain 30.3g of yellow solid, with a yield of 91.2%, an effective content o...

Embodiment 3

[0040] Embodiment 3: the preparation of fluorescent whitening agent ER (o / p)

[0041] Add 13.4g of terephthalaldehyde and 80mL of DMF into a 250mL three-neck flask, add dropwise the methanol solution of 25.3g of o-cyanobenzyl phosphate and 19.3g of sodium methoxide in a constant pressure dropping funnel within 1 hour (content 28%-30%), the temperature is controlled between 10-15°C, and after the dripping is completed, it is kept at 20°C-30°C for 2 hours; then add 25.3g of p-cyanobenzyl phosphate and 3.3g of calcium stearate 19.3g of sodium methoxide solution (content, the same as above) was added dropwise within 1 hour, the temperature was controlled between 20°C and 30°C, and the temperature was kept at 45°C to 50°C for 2 hours after dropping. The reaction solution was beaten with 20mL of methanol, filtered under reduced pressure, washed with 20mL of methanol and 20mL of water in turn, and then dried to obtain 29.7g of a light yellow solid with a melting point of 182-184°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com