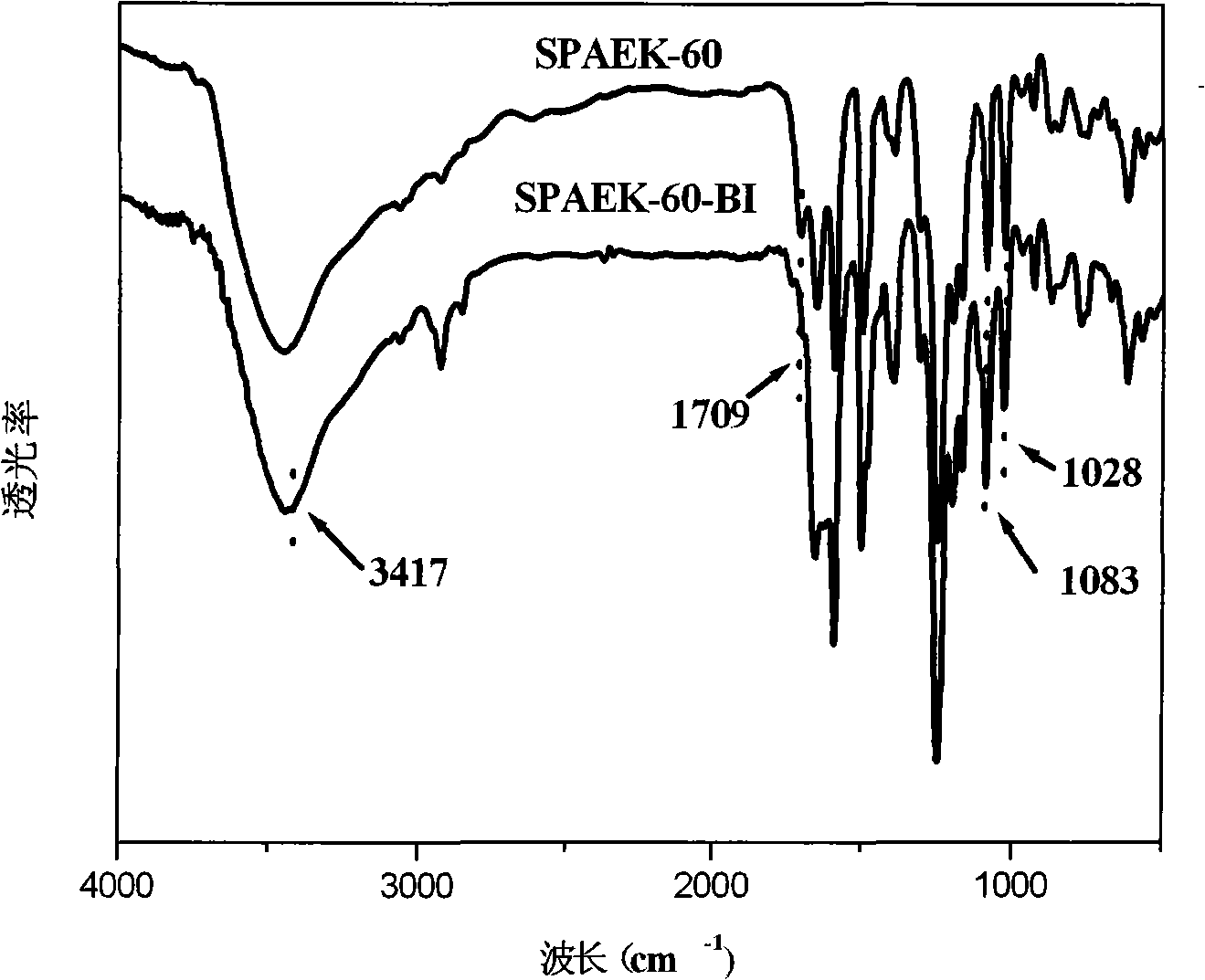

Sulfonated poly(arylene ether ketone) polymer with side chains containing benzimidazolyl in and preparation method thereof

A sulfonated polyaryletherketone and benzimidazole-based technology, which is applied in the field of sulfonated polyaryletherketone polymers and their preparation, can solve the problems of low heat energy recovery and utilization, difficult water and heat management of the system, and catalyst CO poisoning, etc. problems to achieve good proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

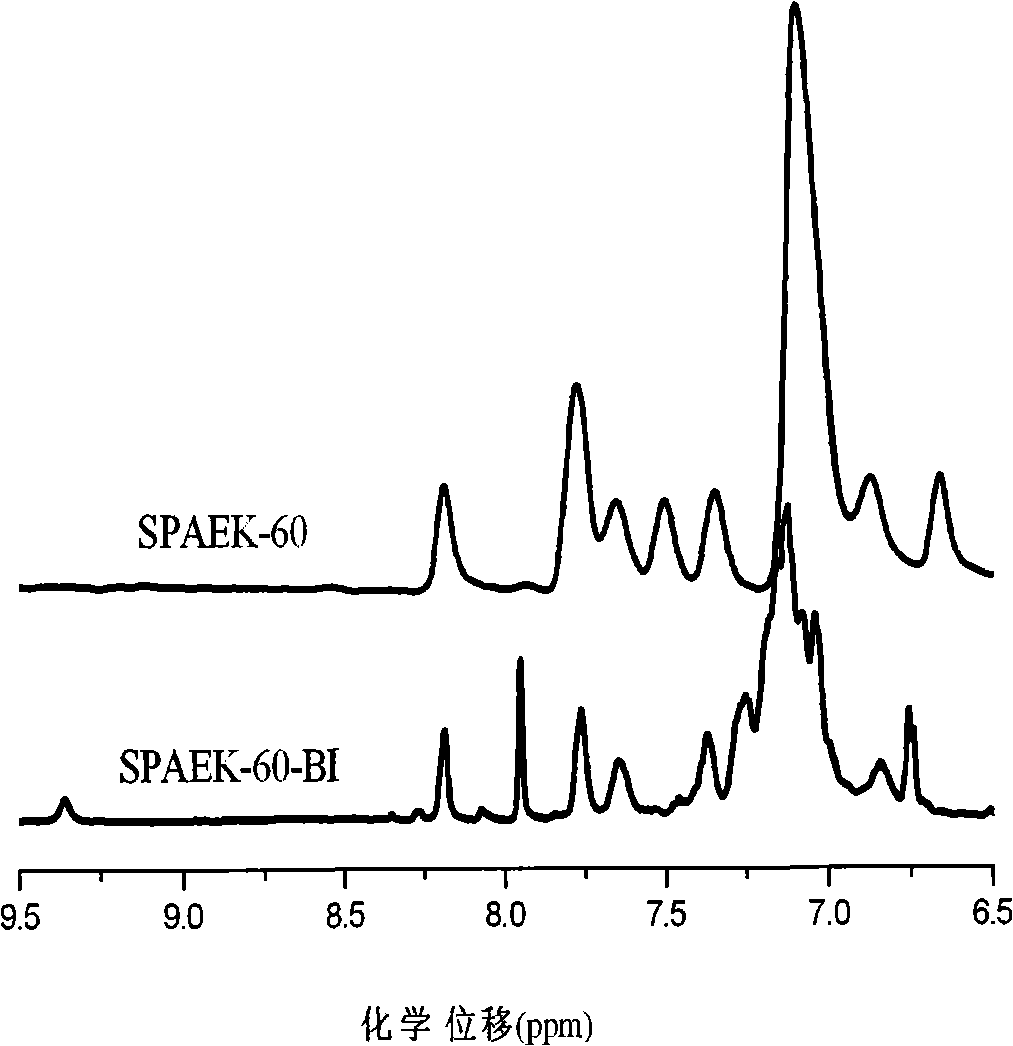

Embodiment 1

[0049] Add a mol 4,4'-difluorobenzophenone, b mol 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, (a+b) mol phenolphthalein into the In the three-necked flask of the stirrer, air guide tube, water separator and condenser tube, 1.8 (a+b) mol of potassium carbonate was used as the salt-forming agent, under a nitrogen atmosphere, dimethyl sulfoxide was used as the solvent, and toluene was used as the solvent. Water-carrying agent, the solid content of the reaction system is 25% (wt), the temperature is raised to 140°C with water for 3 hours, then the toluene is distilled off, and the temperature is raised to 180°C for 4 hours. After reaction finishes, product is poured into the mixed solution of hydrochloric acid and ethanol (V HCl / (V 乙醇 +V HCl )=30%, wherein the massfraction of hydrochloric acid is 37%, and the massfraction of ethanol is 95%), becomes white bar, is pulverized into fine particles with pulverizer, then with Buchner funnel suction filtration, solid powder is ...

Embodiment 2

[0073] Add a mol 4,4'-difluorobenzophenone, b mol 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, (a+b) mol bisphenolic acid to the container In a three-neck flask with a stirrer, an air guide tube, a water separator and a condenser tube, 1.8 (a+b) mol of potassium carbonate is used as a salt-forming agent, under a nitrogen atmosphere, dimethyl sulfoxide is used as a solvent, and toluene It is a water-carrying agent, the solid content of the reaction system is 25% (wt), and water is carried at 140°C for 3 hours, then the toluene is evaporated, and the temperature is raised to 180°C for 4 hours. After reaction finishes, product is poured into the mixed solution of hydrochloric acid and ethanol (V HCl / (V 乙醇 +V HCl )=30%, wherein the massfraction of hydrochloric acid is 37%, and the massfraction of ethanol is 95%), becomes white bar, is pulverized into fine particles with pulverizer, then with Buchner funnel suction filtration, solid powder is used Boil acetone, filter wit...

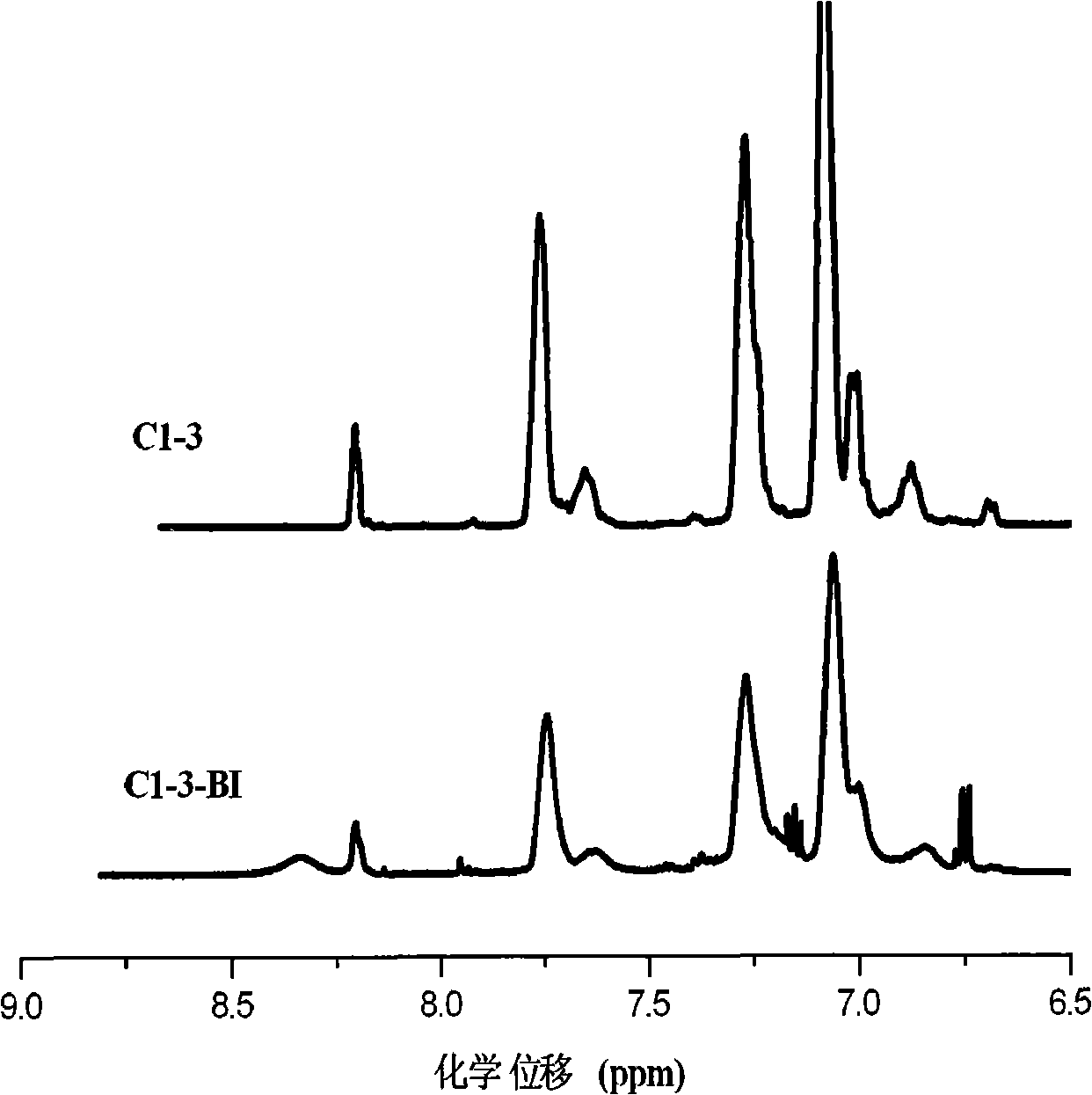

Embodiment 3

[0081] A mol 4,4'-difluorobenzophenone, b mol 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, (a+b)mol 4-(2,5 -dihydroxyphenyl) benzoic acid joins in the there-necked flask that agitator, gas guide tube, water separator and condensation pipe are equipped with, with the potassium carbonate of 1.8(a+b)mol as salt-forming agent, under nitrogen atmosphere, Using dimethyl sulfoxide as a solvent and toluene as a water-carrying agent, the solid content of the reaction system is 25% (wt), carrying water at 140°C for 3 hours, then distilling off the toluene, and raising the temperature to 180°C for 4 hours. After reaction finishes, product is poured into the mixed solution of hydrochloric acid and ethanol (V HCl / (V 乙醇 +V HCl )=30%, wherein the massfraction of hydrochloric acid is 37%, and the massfraction of ethanol is 95%), becomes white bar, is pulverized into fine particles with pulverizer, then with Buchner funnel suction filtration, solid powder is used Boil acetone, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com