Simultaneous sequential chemical extraction of jujube flavones and jujube polysaccharide by fermentation method

A technology of fractional extraction and jujube polysaccharide, applied in the directions of fermentation, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of destroying the flavonoid structure, difficulty in separation work, interference in the extraction and purification of jujube flavonoids, etc. The effect of saving energy and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

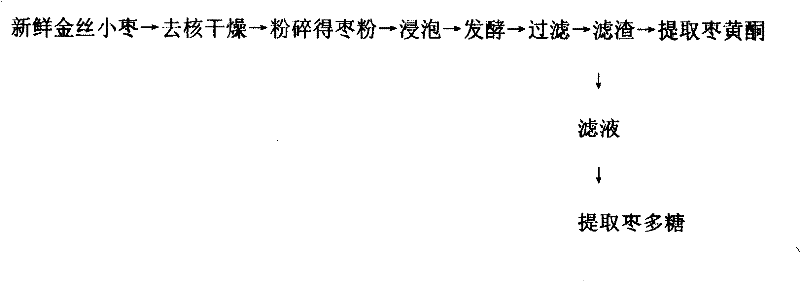

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 gets 1000 grams of jujube powder and commercially available angel yeast and processes as follows:

[0023] a. Soaking: mix jujube powder and water in a ratio of 1:15 (weight ratio), and extract at 70° C. for 4 hours;

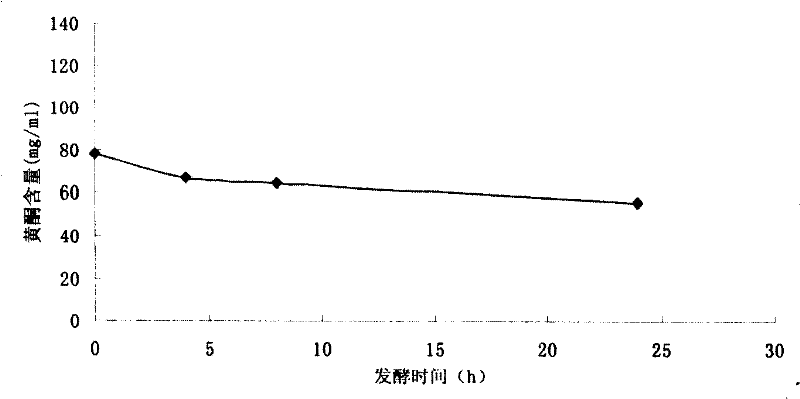

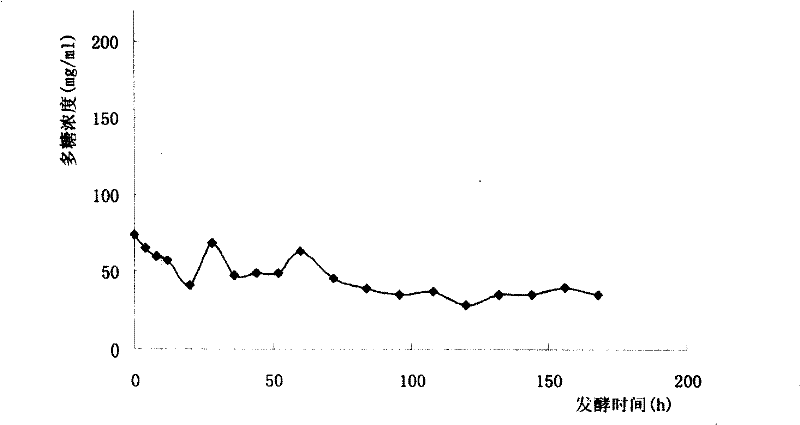

[0024] B, fermentation: add 0.5% (weight ratio) Angel yeast activated in jujube extract liquid, carry out aerobic fermentation at 35 ℃, until the residual sugar amount of reducing sugar is 3% (weight), finish fermentation;

[0025] c. Filtration: use a filter to filter the fermented liquid to obtain filtrate and filter residue;

[0026] d, preparation of jujube polysaccharide: concentrate the filtrate obtained in step c to 1 / 6 of the original volume, ultrafilter, collect the macromolecular phase, concentrate, add 2 times the volume of ethanol (volume fraction is 85%) to precipitate, filter and recover the precipitate, After freeze-drying, use the Sevage method to remove protein, that is, add Sevage reagent (chloroform:n-butanol=5:1) and poly...

Embodiment 2

[0028] Embodiment 2 Get 1000 grams of jujube powder and commercially available angel yeast and process as follows:

[0029] a. Soaking: mix jujube powder and water in a ratio of 1:20 (weight ratio), and extract at 60° C. for 3 hours;

[0030] B, fermentation: add 0.5% (weight ratio) Angel yeast activated in jujube extract, carry out aerobic fermentation at 35 DEG C, until the residual sugar amount of reducing sugar is 2% (weight), finish fermentation;

[0031] c. Filtration: use a filter to filter the fermented liquid to obtain filtrate and filter residue;

[0032] d, preparation of jujube polysaccharide: concentrate the filtrate obtained in step c to 1 / 6 of the original volume, ultrafilter, collect the macromolecular phase, concentrate, add 2 times the volume of ethanol (volume fraction is 85%) to precipitate, filter and recover the precipitate, After freeze-drying, use the Sevage method to remove protein, that is, add Sevage reagent (chloroform:n-butanol=5:1) and polysaccha...

Embodiment 3

[0034] Embodiment 3 Get 1000 grams of jujube powder and commercially available angel yeast and process as follows:

[0035] a. Soaking: mix jujube powder and water in a ratio of 1:15 (weight ratio), and extract at 80° C. for 2 hours;

[0036] B, fermentation: add 0.5% (weight ratio) Angel yeast activated in jujube extract, carry out aerobic fermentation at 35 ℃, until the residual sugar amount of reducing sugar is 2.5% (weight), finish fermentation;

[0037] c. Filtration: use a filter to filter the fermented liquid to obtain filtrate and filter residue;

[0038]d, preparation of jujube polysaccharide: concentrate the filtrate obtained in step c to 1 / 6 of the original volume, ultrafilter, collect the macromolecular phase, concentrate, add 2 times the volume of ethanol (volume fraction is 85%) to precipitate, filter and recover the precipitate, After freeze-drying, use the Sevage method to remove protein, that is, add Sevage reagent (chloroform:n-butanol=5:1) and polysaccharid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com