Process for producing epoxy resin//MC nylon composite material

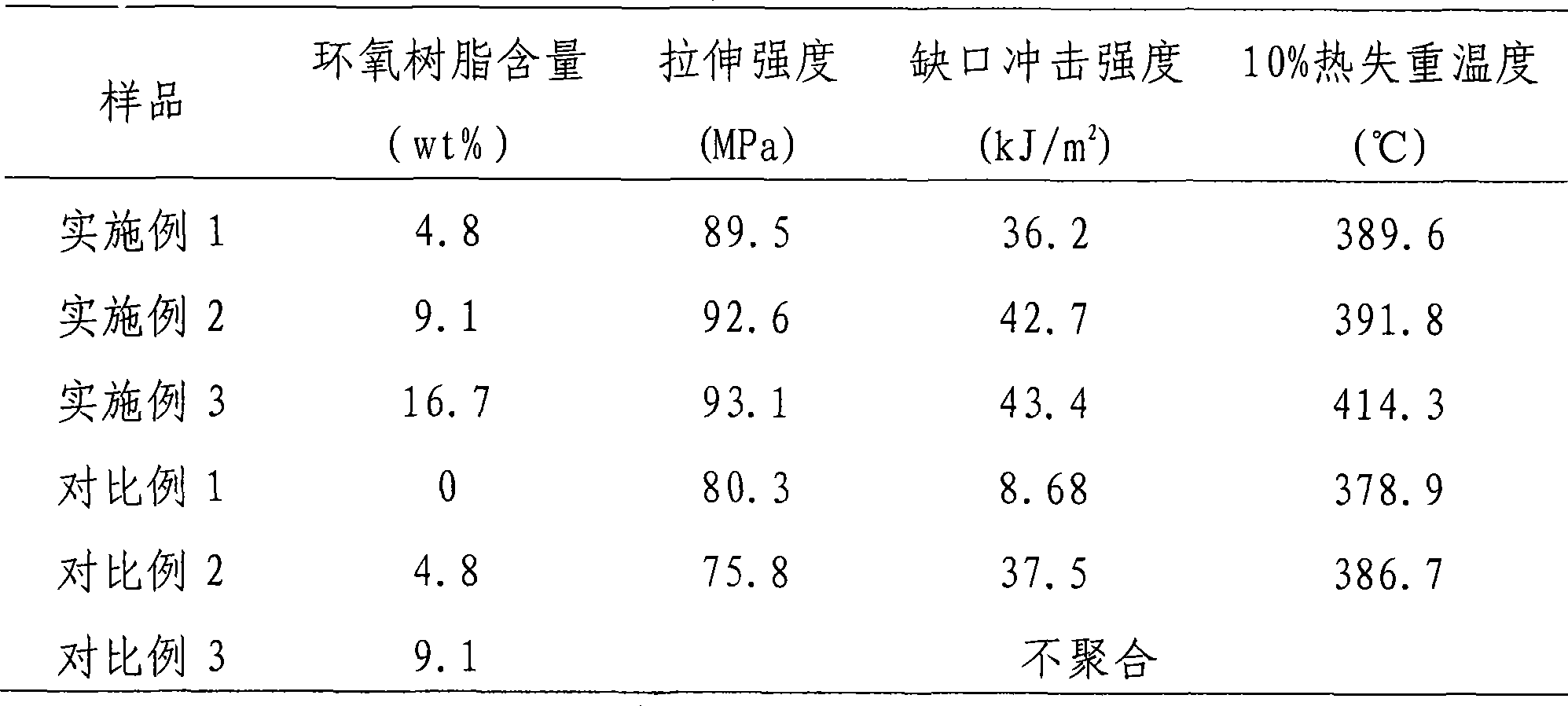

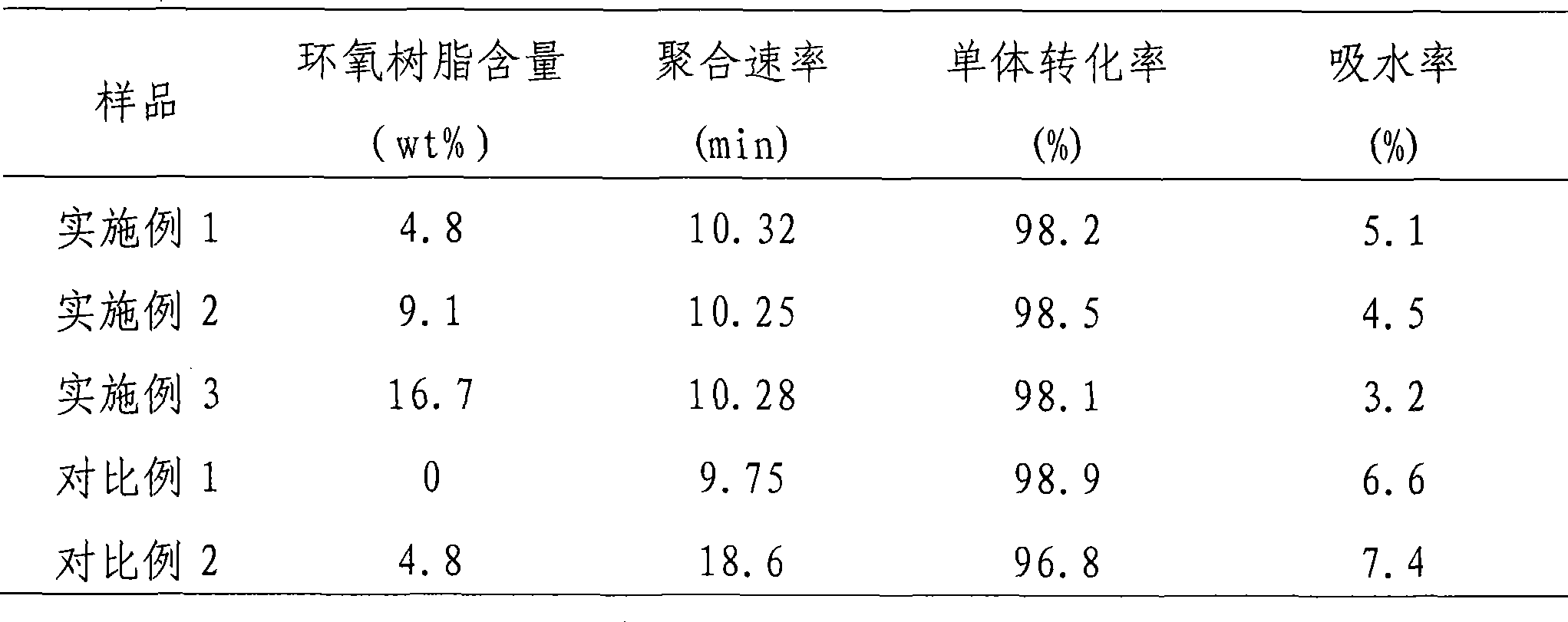

A nylon composite material and epoxy resin technology, which is applied in the field of MC nylon 6 composite material preparation, can solve the problems of increased unpolymerized caprolactam monomer content, decreased polymerization speed, prolonged gel time, etc., and achieves fast polymerization rate and impact strength. Improved, short gel time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, in reactor, add 200g caprolactam, under nitrogen protection, add 10g bisphenol A type epoxy resin, stir, then add 1g 4,4'-diaminodiphenyl sulfone (DDS), heat To 130°C, react at this temperature for 30min, then switch to the vacuum system, vacuum dehydrate at 130°C for 20min; then release the vacuum, add 0.287g sodium methoxide, react under 750mmHg vacuum degree, wait until the melt temperature rises to about 140°C , maintained for 15min; after releasing the vacuum, quickly add (activator) 0.924g of 2,4-toluene diisocyanate, mix quickly and pour into a mold preheated to 165°C, polymerize in a constant temperature drying oven at 165°C for 30min, stop Heating, cooling to room temperature naturally, and demoulding to obtain epoxy resin / MC nylon 6 composite material.

Embodiment 2

[0021] Embodiment 2, in reactor, add 200g caprolactam, under nitrogen protection, add 20g bisphenol A type epoxy resin, stir, then add 2.5g 4,4'-diaminodiphenyl sulfone (DDS), heat to 130°C, react at this temperature for 30 minutes, then switch to the vacuum system, and vacuum dehydrate at 130°C for 20 minutes; then release the vacuum, add 0.287g of sodium methoxide, and react at a vacuum of 750mmHg. When the melt temperature rises to about 140°C, Maintain for 15 minutes; after releasing the vacuum, quickly add 0.924 g of 2,4-toluene diisocyanate, mix quickly and pour into a mold preheated to 165°C, polymerize in a constant temperature drying oven at 165°C for 30 minutes, stop heating, and cool naturally to After room temperature, the mold is demolded to obtain the epoxy resin / MC nylon 6 composite material.

Embodiment 3

[0022] Embodiment 3, in the reactor, add 200g caprolactam, under nitrogen protection, add 40g bisphenol A type epoxy resin, stir and mix, then add 5g4,4'-diaminodiphenyl sulfone (DDS), heat to 130 ℃, react at this temperature for 30min, then switch to the vacuum system, and dehydrate in vacuum at 130℃ for 20min; then release the vacuum, add 0.287g sodium methoxide, and react at a vacuum of 750mmHg, wait until the melt temperature rises to about 140℃, maintain 15min; after releasing the vacuum, quickly add 0.924g of 2,4-toluene diisocyanate, mix quickly and pour into a mold preheated to 165°C, polymerize in a constant temperature drying oven at 165°C for 30min, stop heating, and naturally cool to room temperature After that, demould to get the epoxy resin / MC nylon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com