Modified starch slurry used for heat-sensitive chaine low temperature starching and preparation method thereof

A modified starch, heat-sensitive technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of decreased adhesion performance, temperature sensitivity of slurry, poor flow, etc., to achieve good fluidity and thermal stability, resistance The effect of strong gel and high adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The raw corn starch was subjected to acidolysis and viscosity reduction treatment. The raw corn starch is mixed with water to form a starch suspension with a concentration of 40%, heated to 50° C. under stirring, and dilute hydrochloric acid is added and stirred to react to the required starch viscosity. After the reaction, neutralize to pH 7 with dilute NaOH solution, wash, filter and dry to obtain acid-thinned starch.

[0020] Make starch suspension with the starch and water after acidolysis and viscosity reduction in the ratio of 1:1.5, adjust the pH of the system to 10 with NaOH solution with a concentration of 3%, and then add dropwise at 24°C and pH 9-10 For vinyl acetate with 5% starch mass, the dropping speed is controlled within 0.5 h, and the reaction is continued for 1 h after the dropping is completed, and then adjusted to pH 7 with dilute hydrochloric acid. Acetate starch is obtained after suction filtration, washing, drying and crushing.

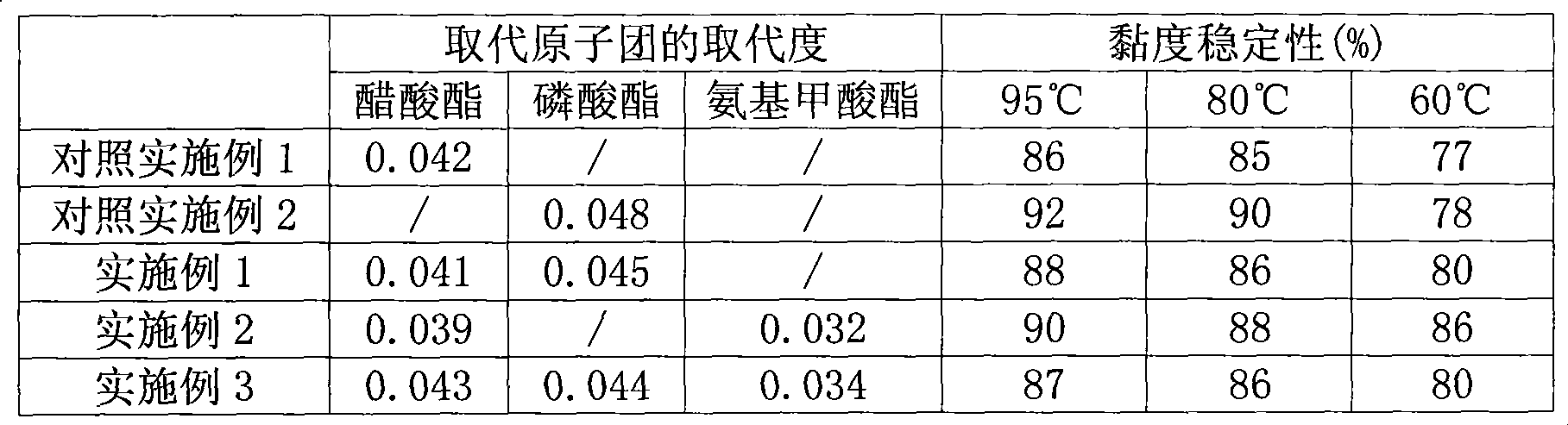

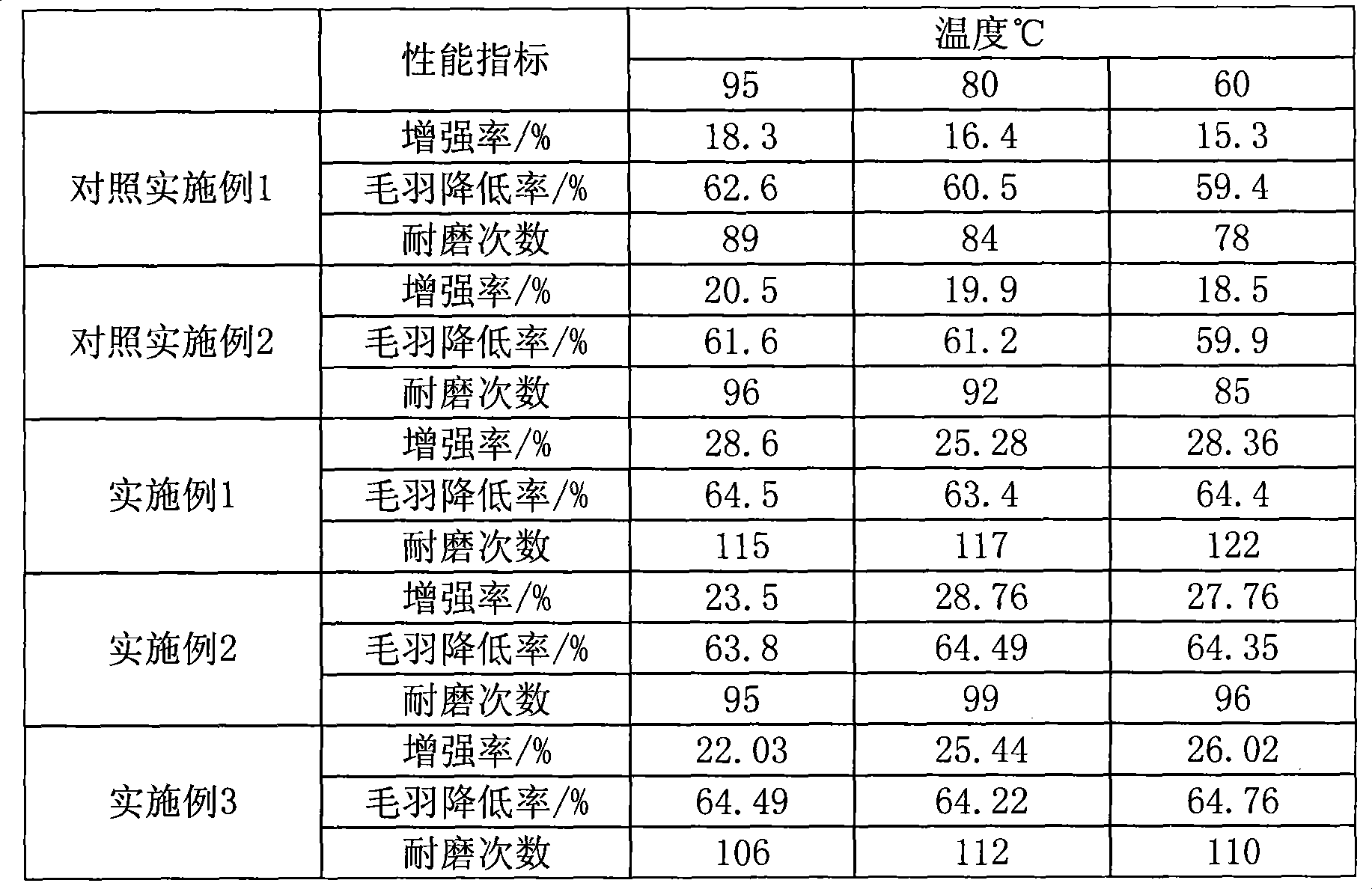

[0021] Dissolv...

Embodiment 2

[0024] The acetate starch obtained in Example 1 was made into a starch suspension with water at a ratio of 1:1.5, and 8% urea and 2% ammonium chloride were added to the starch mass, stirred at room temperature for 1 hour and then filtered, then in Pre-dry at 50°C until the water content is 10%, then react at 110°C for 2 hours, wash the product thoroughly, filter, and dry to obtain acetate-carbamate modified starch slurry.

[0025] The degree of substitution of the acetate group in the product is DS a =0.039, the degree of substitution of the carbamate group is DS n = 0.032. See Table 1, Table 2 and Table 3 for the viscosity and stability of hot paste, the adhesion performance to viscose and wool fiber, and the sizing performance to wool warp yarn.

Embodiment 3

[0027] Mix the acetic acid-modified starch obtained in Example 1 with water at a ratio of 1:1.5 to form a starch suspension, add 5% sodium dihydrogen phosphate, 5% disodium hydrogen phosphate and 8% urea to the starch quality, and stir at room temperature Suction filtration after 1h, pre-dry the starch filter cake at 50°C until the water content is 10%, grind it and react it at 150°C for 2h, then wash the product fully, filter, and dry to obtain acetate-phosphorylation - Urethanized multiple esterified modified starch size.

[0028] The degree of substitution of the acetate atom group in the product is DSa =0.043, the substitution degree of phosphate ester atomic group is DS p =0.044, the degree of substitution of the carbamate group is DS n = 0.034. See Table 1 and Table 2 for the viscosity and stability of the hot paste, and the adhesion properties to viscose and wool fibers, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com