Non-leaching surface-active film compositions for microbial adhesion prevention

A surfactant and composition technology, applied in the field of antimicrobial film-forming compositions, can solve problems such as time reducing efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

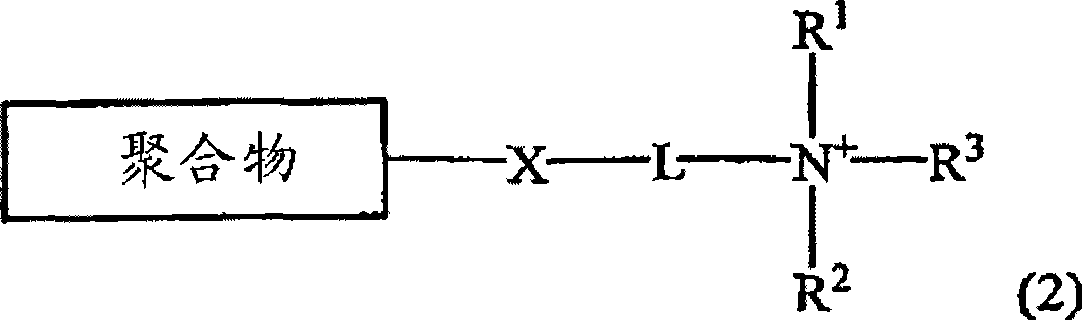

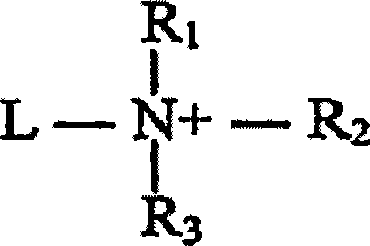

Method used

Image

Examples

preparation example Construction

[0121] Preparation of coating solution

[0122] Coating solutions comprising PU and optionally PVP were prepared according to the prior art. To these solutions were added 10% of a polyurethane prepolymer containing about 6% free isocyanate groups (determined by titration prior to addition).

[0123] The percent concentration of isocyanate present in the polyurethane prepolymer was determined using 25 ml of a 0.1N solution of dibutylamine (slightly over the expected amount) and mixed for 15 minutes. For the bromophenol blue indicator, titrate the excess with 0.1 n HCl until a pale yellow color is seen.

[0124] Preparation and use of coating solutions

[0125] The coating solution comprising free isocyanate is briefly mixed, then 5% to 15% of a 40 to 90% aqueous solution of a quaternary ammonium compound (comprising the reactive groups according to the invention) is added and mixed briefly again. The mixture was set aside for observation to first assess reactivity. The mixt...

Embodiment 1

[0135] Example 1 - Using the starting coating solution according to Example 1 of US Patent 4,642,267, a typical medical base formulation for the use of the present invention was prepared as follows:

[0136] To a mixture of 75 grams of diacetone alcohol and 25 grams of butanone were added 4 grams of polyvinylpyrrolidone (Kollidon 90, BASF Corp.) and 2 grams of linear polyurethane (Estane 5703, B.F. Goodrich Co.). To 10 g of the resulting solution were added 0.5 g of linear polyurethane polyisocyanate prepolymer (NORDOT Adhesive 34D-2, SyntheticSurfaces, Inc.) and 0.25 g of quaternary ammonium compound 3-chloro-2-hydroxypropyl- Stearoyl-dimethylammonium chloride (Quab 426). The obtained solution is applied to such a substrate as polyurethane resin and allowed to dry. The resulting coating is a highly durable coating that is smooth when wet and has antimicrobial properties by preventing bacterial colonization and does not lose efficacy in prolonged leaching. During the initial...

Embodiment 2

[0137] Example 2 - Utilizing the starting coating solution according to Example 1 of US Patent 4,467,073, a typical anti-fog base formulation for use in the present invention was prepared as follows:

[0138] Dissolve 2.5 grams of polyvinylpyrrolidone, PVP-K90, in 100 ml of a mixture of 75% diacetone alcohol and 25% cyclohexane, followed by dissolving 1.0 grams of dioctyl sodium sulfosuccinate surfactant and 5.0 grams of Tycel 7351 isocyanate Prepolymer (Hughson Chemicals, Lord Corporation). To 10 g of the resulting solution were added 0.5 g of linear polyurethane polyisocyanate prepolymer (NORDOT Adhesive 34D-2, Synthetic Surfaces, Inc.) and 0.25 g of the quaternary ammonium compound 3-chloro-2-hydroxypropyl - Cocoalkyl-dimethylammonium chloride (Quab 360). Coatings applied according to this composition and cured for 24 hours at 72°F were clear, colorless, hard and scratch resistant and did not fog up when cooled to 32°F and then stored in a beaker of boiling water. The coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com