Insecticidal composition containing thiacloprid and butene-fipronil

A technology of butene fipronil and an insecticidal composition, which is applied in the field of pesticides, can solve problems such as environmental pollution, and achieve the effects of less environmental pollution, convenient storage, transportation and use, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: 10% thiacloprid·butene fipronil water dispersible granules

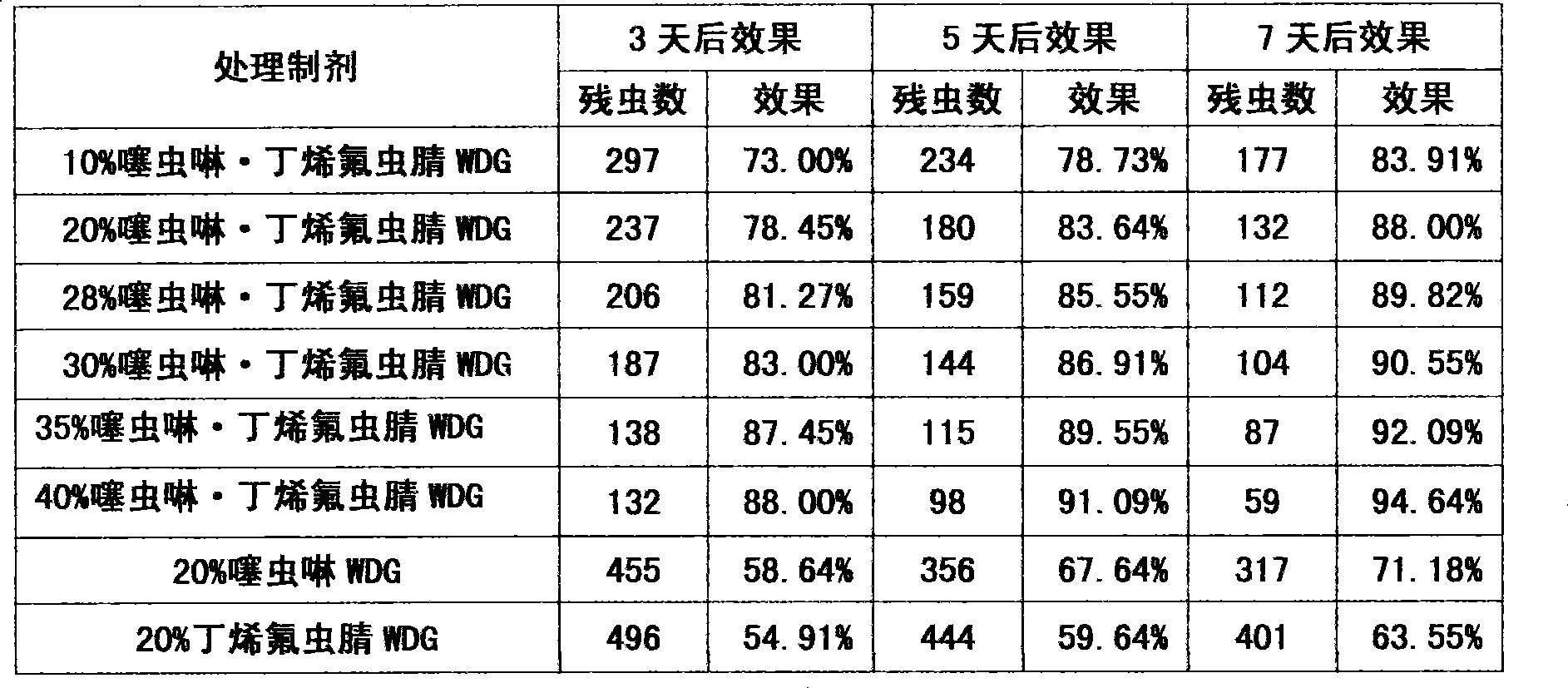

[0024] Prepare 10% thiacloprid·butene fipronil water dispersible granules according to the following proportions, spray evenly at 1500 times to control rice planthoppers, and compare the control effects on 3 days, 5 days and 7 days after application.

[0025] Weigh 5g of thiacloprid technical material, 5g of butylene fipronil, 1g of saponin powder, 5g of sodium lignosulfonate, 5g of ammonium sulfate, and 20g of light calcium carbonate, and mix them according to the general method. Mix the parent powder with 2g of polyvinylpyrrolidone evenly, then supplement it with kaolin to 100g, then granulate, dry and sieve to obtain 10% thiacloprid-butene-fipronil water dispersion Granules. After testing, the active ingredient content is 10%, the suspension rate is ≥75%, the moisture content is ≤2.5%, the pH is 7.1, the particle size range (225-800um) is ≥98%, the dispersibility is ≥85%, the wetting time is ≤90...

Embodiment 2

[0026] Example 2: 20% thiacloprid·butene fipronil water dispersible granules

[0027] Prepare 20% thiacloprid·butene fipronil water dispersible granules according to the following proportions, spray evenly at 1500 times to control rice planthoppers, and compare the control effects on 3 days, 5 days and 7 days after spraying.

[0028] Weigh 5 g of thiacloprid technical material, 15 g of butylene fipronil, 3 g of pull-off powder, 5 g of carboxymethyl cellulose, 2 g of ammonium bicarbonate, and 25 g of white carbon black, mix them according to the general method, stir evenly, and Mix the parent powder with 3g of polyethylene glycol evenly, then supplement it with soluble starch to 100g, then granulate, dry and sieve to obtain 20% thiacloprid-butene-fipronil Water-dispersible granules. After testing, the active ingredient content is 20%, the suspension rate is ≥75%, the water content is ≤2.5%, the pH is 7.1, the particle size range (225-800um) is ≥98%, the dispersibility is ≥85%,...

Embodiment 3

[0029] Example 3: 28% thiacloprid·butene fipronil water dispersible granules

[0030] Prepare 28% thiacloprid·butene fipronil water dispersible granules according to the following proportions, spray evenly at 1500 times to control rice planthoppers, and compare the control effects on 3 days, 5 days and 7 days after spraying.

[0031] The original drug thiacloprid 8g, butene fipronil 20g, sodium lauryl sulfate 5g, pull open powder 1g, ammonium sulfate 4g, polyethylene glycol 1g, kaolin 61g, fully stirred and mixed, ground and granulated to prepare 28% thiacloprid·butene fipronil water dispersible granules. After testing, the active ingredient content is 28%, the suspension rate is ≥75%, the water content is ≤2.5%, the pH is 7.1, the particle size range (225-800um) is ≥98%, the dispersibility is ≥85%, the wetting time is ≤90s, and the wet sieve test ( Through 75μm sieve) ≥ 98, long-lasting foaming (after 1min) ≤ 12ml, qualified for accelerated thermal storage stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com