Acaricide composition containing tebufenpyrad and azocyclotin with synergistic action

A technology of pyrimidine and triazotin, which is applied in the field of compound acaricides, can solve the problems of high cost and large dosage, and achieve the effects of reducing dosage, maintaining effective control effect, and good environmental compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

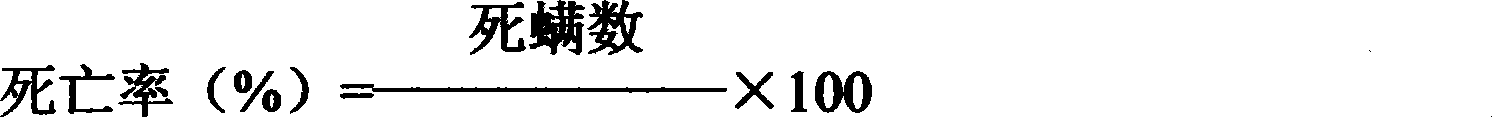

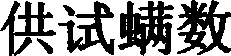

Method used

Image

Examples

Embodiment 1

[0014] Preparation of 30% tebufenpyrad·triazoltin wettable powder (effective drug ingredient 5:25):

[0015] Auxiliary selection: sodium lignosulfonate, penetrant T.

[0016] Filler selection: light calcium carbonate.

[0017] Each component is prepared according to weight percentage:

[0018] Tebuflufen: 5%; tin triazole: 25%; 14 grams of sodium monocalcium lignosulfonate, 3 grams of penetrant T, and the balance of light calcium carbonate to 100 grams.

[0019] Preparation process: Add tebufenpyrad, tin triazolate, sodium monocalcium lignosulfonate, penetrant T, and the balance of light calcium carbonate to 100 grams. The above raw materials are put into the mixing tank according to the conventional method of preparing wettable powder and mixed to form wettable powder.

Embodiment 2

[0021] The configuration of 55% tebufenpyrad·triazoltin suspoemulsion (active pharmaceutical ingredient 5:50):

[0022] Auxiliary selection: sodium lignosulfonate, OP-10; CMC; organosilicone; ethylene glycol.

[0023] Solvent of choice: water.

[0024] Each component is prepared according to weight percentage:

[0025] Tebufenpyrad: 5%; Triazol tin: 50%; Sodium lignosulfonate: 10%; OP-10: 5%; Thickener CMC: 1%; Defoamer silicone: 0.01%; Antifreeze Ethylene glycol: 8%; water: balance.

[0026] Preparation process: Put tebufenpyrad, tin triazole, sodium lignosulfonate, OP-10, thickener CMC, defoamer organic silicone, antifreeze ethylene glycol in the reaction kettle according to the above ratio, add water Mix evenly until 100%, and then introduce the mixture into a sander to grind until the material fineness is 1-5um; after grinding, mix evenly to form a suspoemulsion.

Embodiment 3

[0028] The configuration of 18% tebufenpyrad·triazoltin emulsifiable concentrate (active drug ingredient 10:8):

[0029] Auxiliary selection: calcium dodecyl basic sulfonate and phenethylphenol polyoxyethylene ether mixture

[0030] Filling accessories selection: xylene.

[0031] Tebuflufen: 10%; Triazol tin: 8%; Calcium dodecyl sulfonate and phenethylphenol polyoxyethylene ether mixture: 8%; Xylene: appropriate amount.

[0032] Put the mixture of tebufenpyrad, tin triazolium, calcium dodecyl sulfonate and phenethylphenol polyoxyethylene ether in the mixer according to the above ratio, and fill it with xylene to 100%; prepare the above raw materials as conventional EC Put it into a mixing kettle and mix at high speed to form an emulsifiable cream.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com