Catalyst for selective oxidation of sulfureted hydrogen into elemental sulfur and reaction process thereof

A catalyst, hydrogen sulfide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, sulfur preparation/purification, etc., can solve the problems of reducing sulfur yield, complex structure and high cost , to achieve the effect of high conversion rate and good low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Wash industrial metatitanic acid with deionized water to ensure that (SO 4 ) -2 ≤0.1%, dried at 120°C for 4 hours, crushed to 180 mesh. Get above-mentioned 160g of metatitanic acid and 40g of industrial activated alumina powder and 4g of turnip powder and mix evenly. Weigh 24.3g (NH 4 ) 3 Fe(·C 6 h 5 o 7 ) 2 and 5.4g Cr 2 (C 2 o 4 ) 3 4H 2 O, dissolved in distilled water, with HNO 3 After adjusting the pH value of the solution to 4-5, add it to the above powder and stir, knead, extrude into a Φ4.0mm columnar shape, dry naturally at room temperature for 8 hours, dry at 120°C for 2 hours and roast at 450°C for 4 hours. The catalyst sample A was obtained. Its chemical composition is: TiO 2 81.2% (m / m), containing iron, 8.1% chromium oxide, the measured specific surface area of the sample is 128m 2 / g, crushing strength 134N / cm, activity results are shown in Table 1.

Embodiment 2

[0037] The catalyst prepared in Example 1 is broken into 20 mesh-10 mesh particle size, and 10ml of sample is packed into a stainless steel reactor with an internal diameter of Φ18mm, and a layer of quartz sand with a thickness of 4cm is placed on it to ensure that the reactor is evenly mixed and reacted. The inlet gas contains H 2 S1% (V), O 2 0.8% (V), H 2 O10% (V), the rest is N 2 . The activity of the catalysts was evaluated using a small laboratory setup.

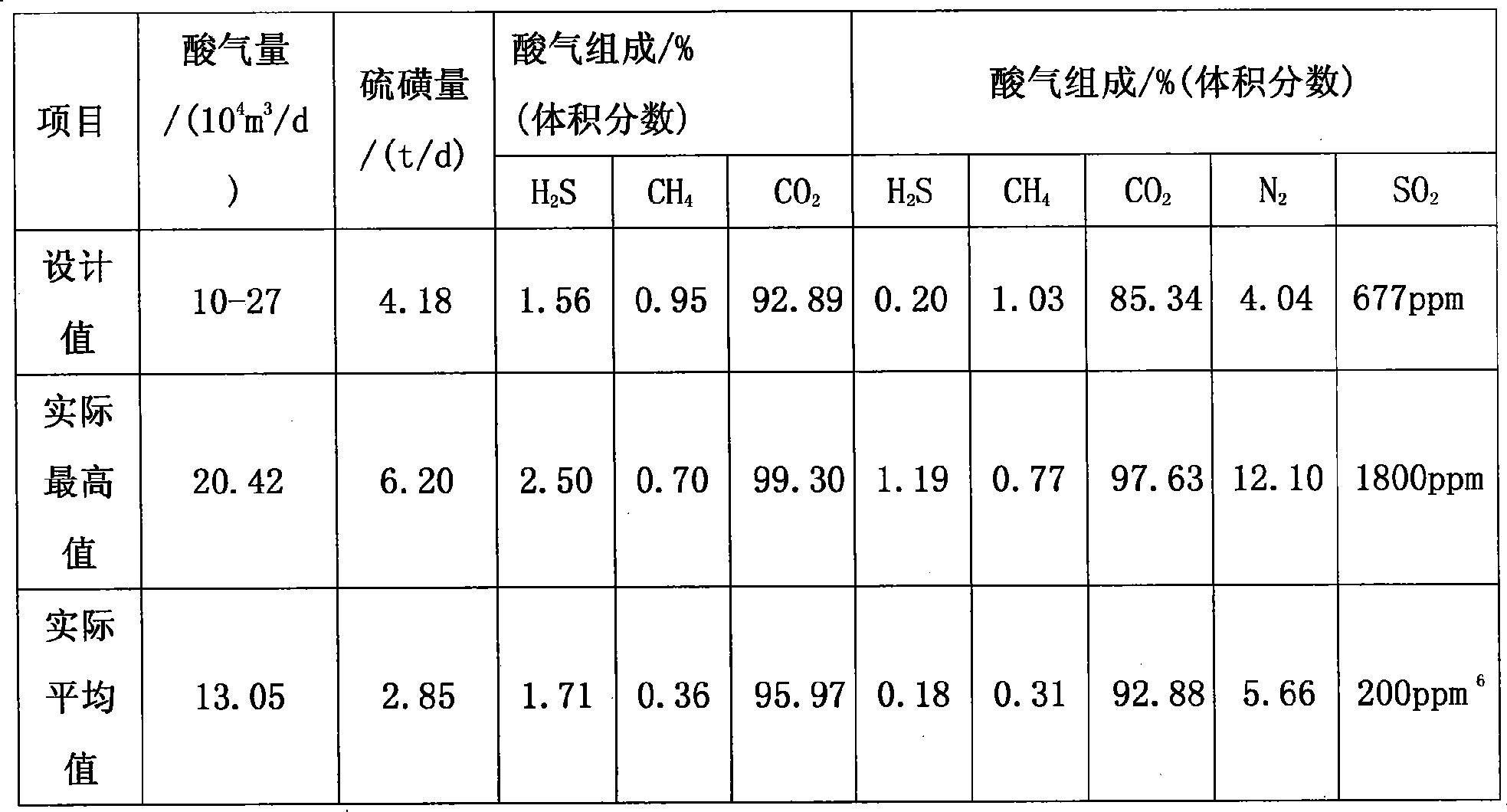

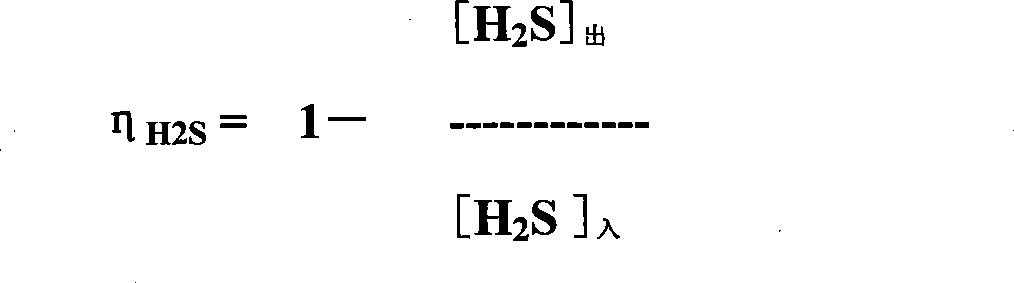

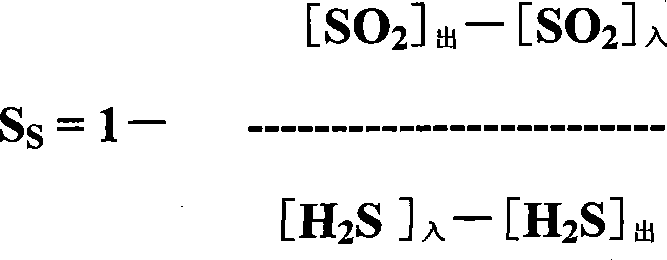

[0038] All tests are carried out under typical conditions of 180, 200, 220, 240°C and 2000h-1 high space velocity. Gas volume composition H 2 S: 1.0%, CO 2 :98,O 2 :0.8%. h 2 S conversion rate η H2s %, selectivity S s % and sulfur yield S% are calculated as follows:

[0039]

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com