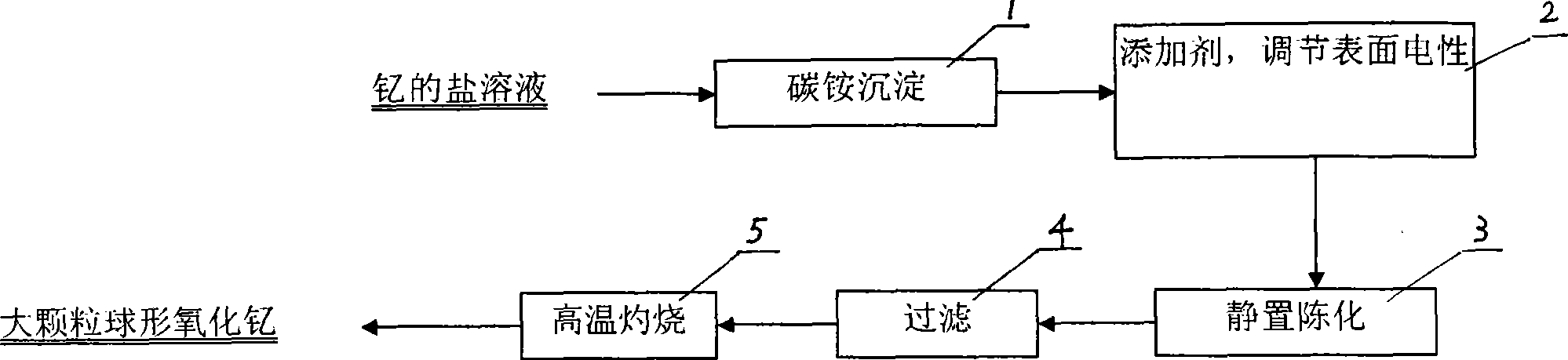

Method for preparing large granularity and large specific surface area spherical yttrium oxide

A large specific surface area, yttrium oxide technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of large specific surface area yttrium oxide, poor fluidity, large particle size, etc., to achieve easy industrial operation, Large sediment particle size and good filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

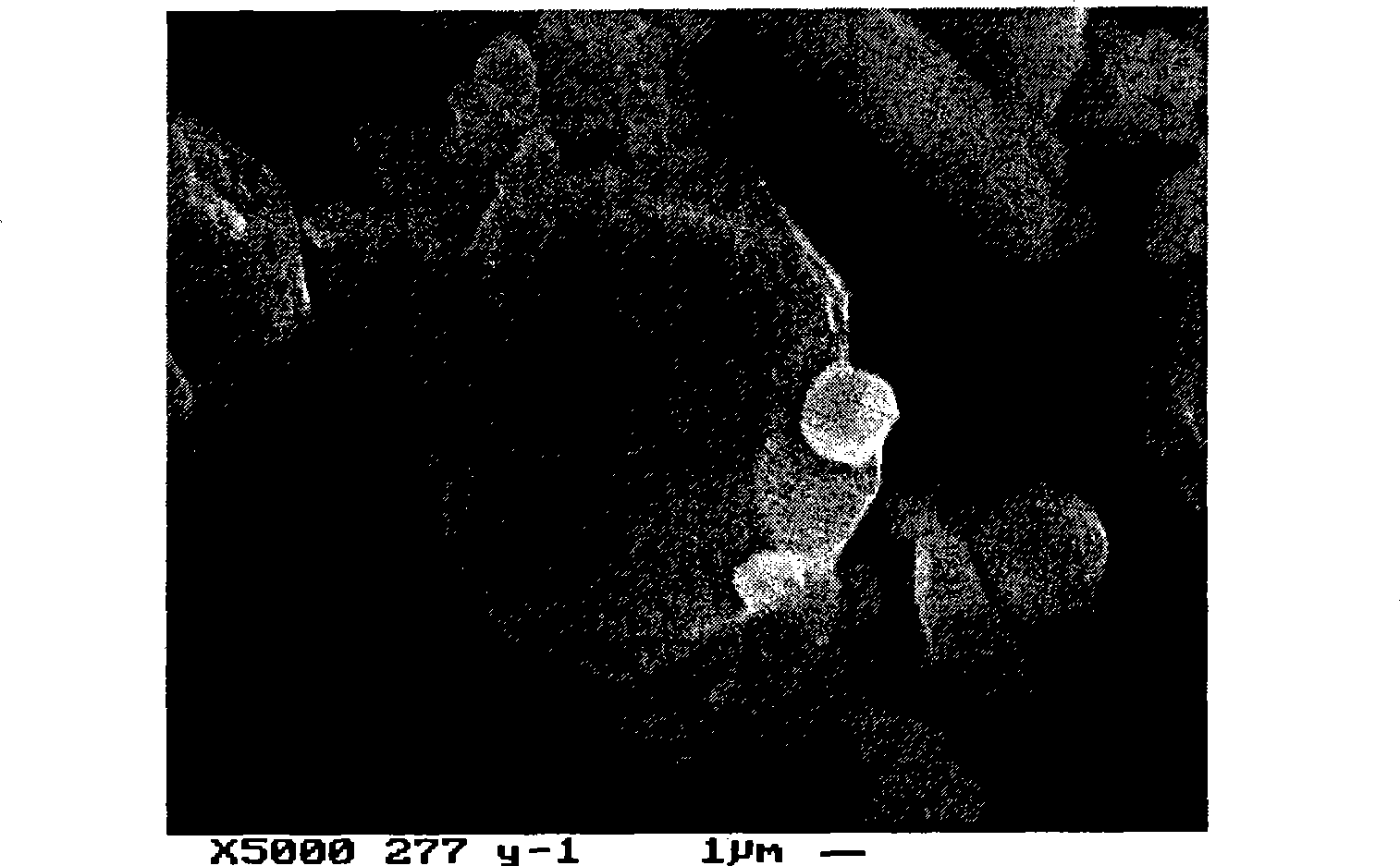

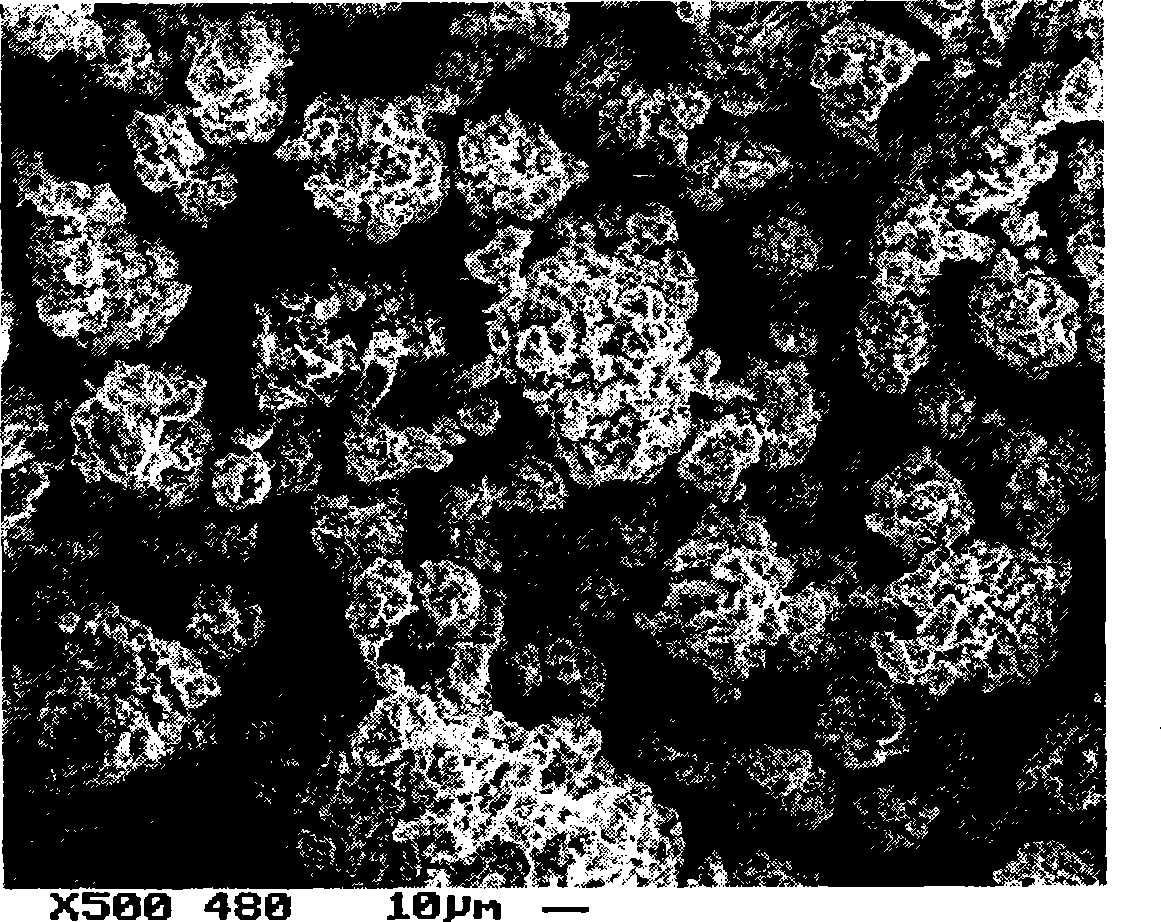

Embodiment 1

[0034] 50 L of yttrium nitrate solution with a concentration of 0.5 mol / L and a pH of 4 was added under stirring to an ammonium bicarbonate solution with a concentration of 0.5 mol / L, so that the amount of ammonium bicarbonate was 3.2 times the number of moles of yttrium. During the addition of ammonium bicarbonate, a white precipitate is formed. After the addition of ammonium bicarbonate is completed, add ammonium nitrate solid at a slurry concentration of 0.3mol / L, continue stirring, and stop stirring at 38°C for 36 hours. The slurry Filter and wash to obtain the precursor powder, measure the Zeta potential of the precursor, and calcinate at 720°C to obtain a large-particle spherical yttrium oxide product. The particle size and specific surface area of the product are measured, and the results are shown in Table 1.

Embodiment 2

[0036]50 L of yttrium nitrate solution with a concentration of 2.0 mol / L and a pH of 4 was added to an ammonium bicarbonate solution with a concentration of 2.0 mol / L under stirring, so that the amount of ammonium bicarbonate was 3.2 times the number of moles of yttrium. During the addition of ammonium bicarbonate, a white precipitate is formed. After the addition of ammonium bicarbonate is completed, add ammonium nitrate solid at a slurry concentration of 0.05mol / L, continue to stir, stop stirring, and stand at 38°C for 36 hours. The slurry Filter and wash to obtain the precursor powder, measure the Zeta potential of the precursor, and calcinate at 720°C to obtain a large-particle spherical yttrium oxide product. The particle size specific surface area of the product is measured, and the results are shown in Table 1.

Embodiment 3

[0038] 50 L of yttrium nitrate solution with a concentration of 1.0 mol / L and a pH of 4 was added to an ammonium bicarbonate solution with a concentration of 1.0 mol / L under stirring, so that the amount of ammonium bicarbonate was 3.2 times the number of moles of yttrium. During the addition of ammonium bicarbonate, a white precipitate is formed. After the addition of ammonium bicarbonate is completed, add ammonium nitrate solid at a slurry concentration of 0.10mol / L, continue stirring, stop stirring, and stand at 38°C for 36 hours. The slurry Filter and wash to obtain the precursor powder, measure the Zeta potential of the precursor, and calcinate at 720°C to obtain a large-particle spherical yttrium oxide product. The particle size specific surface area of the product is measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com