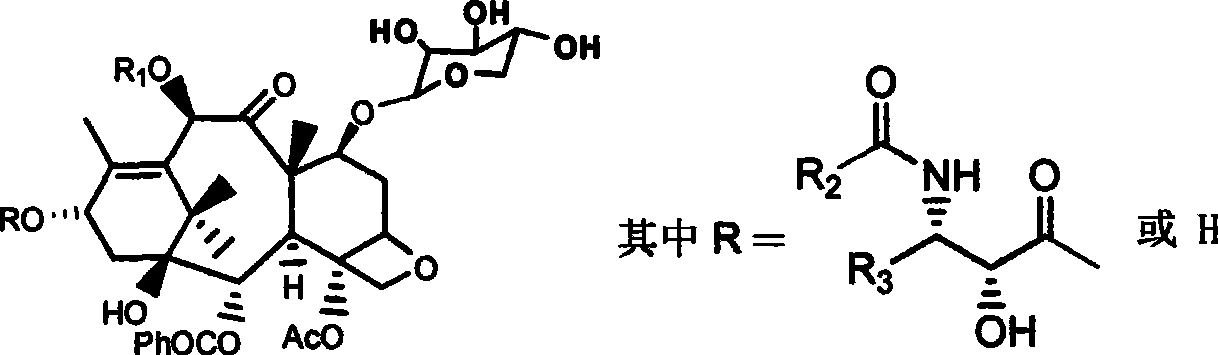

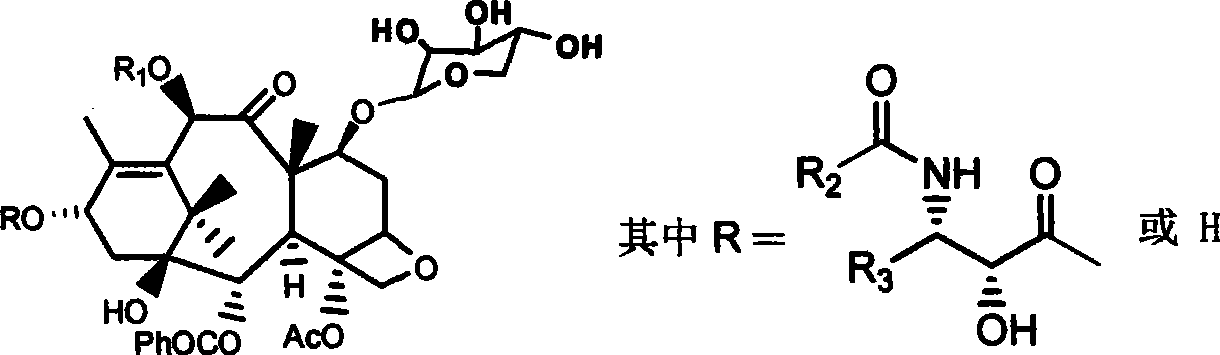

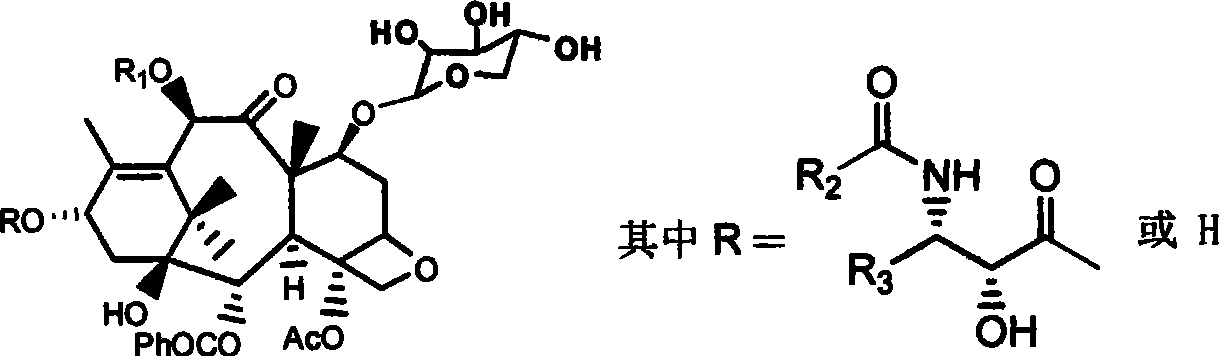

Fibrized cellulomonas cartae, hydrolase and application thereof in taxane conversion aspect

A cellulomonas and hydrolytic enzyme technology, applied in the field of biochemistry, can solve the problems of unsuitability for industrial production, reduced hydrolysis efficiency, and low microbial enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Hydrolysis of 7-xylose-paclitaxel by Cellulomonas fibrosis CCTCC No.M 207130

[0039] A medium (pH 7.0 before sterilization) containing 1% glycerol, 0.2% peptone, 0.2% yeast extract, and 0.2% dipotassium hydrogenphosphate was used as a seed medium.

[0040] Distribute 20ml of the above-mentioned seed medium into 100ml conical flasks, sterilize at 120°C for 15min, inoculate 1 inoculation loop of the agar slant culture of Cellulomonas cellulosus XZ-5 strain into it, and inoculate it at 30°C Cultured with shaking for 2 days as a seed solution.

[0041] Put 100ml of 1% starch, 0.2% yeast extract, 0.2% ammonium chloride, 0.1% NaH into a 500ml Erlenmeyer culture bottle 2 PO 4 and 0.1% Na 2 HPO 4 Medium, pH7, autoclaved at 121°C for 30min. Inoculate 1ml of seed liquid into this medium, shake the flask at 150rpm, and culture at 30°C for 5 days. Centrifuge to collect the supernatant, which is the crude enzyme solution.

Embodiment 2

[0048] Example 2: Hydrolysis of 7-xylose-10-deacetyl-paclitaxel by Cellulomonas cellulosus CCTCC No.M 207130 and purification of the product

[0049] Add 10ml of 7-xylose-10-deacetyl-paclitaxel methanol solution (concentration: 5mg / ml) to 90ml of the crude enzyme solution described in Example 1, 50rpm, react at 30°C for 20 hours, then add 20ml of ethyl acetate Extraction, total extraction 3 times, combined upper organic phase, evaporated to dryness under reduced pressure, obtains 105mg of solid matter, goes up silica gel column (20g) and carries out elution with chloroform:methanol (98:2), obtains 40mg10-deacetylpaclitaxel (yield 91%).

Embodiment 3

[0050] Example 3: Hydrolysis of Cellulomonas cellulosus CCTCC No.M 207130 mixed taxane xylosides and purification of products

[0051] Put 500ml of 1% birch xylan, 0.5% urea, 0.2% KH in a 2000ml Erlenmeyer culture bottle 2 PO 4 and 0.1% K 2 HPO 4 Medium, pH 7, autoclaved for 30 min. 10ml of the seed solution described in Example 1 was inoculated in this medium, and cultured in shake flasks at 30° C. for 2 days at 200 rpm. The supernatant was collected by centrifugation and stored at -20°C for later use. Mix 200ml containing 7-xylose-10-deacetyltaxol, 7-xylose-10-deacetylcephalomannine, 7-xylose-10-deacetyltaxol C (from natural yew extract Separated, methanol solutions (5 mg / ml) with contents of 65%, 9.9%, and 3.3%) were added to 2000 ml of the crude enzyme solution as described above, 50 rpm, and reacted at 35° C. for 8 hours. The reaction solution was extracted three times with ethyl acetate, 200ml each time, the combined organic phases were evaporated to dryness and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com