Production method and strain of gamma-aminobutyric acid (GABA)

A technology of aminobutyric acid and production method, applied in the field of genetic engineering, can solve the problems of complex GABA process and high production cost, and achieve the effect of simplifying production steps and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Acquisition of the glutamic acid decarboxylase gene gadB1

[0019] A γ-aminobutyric acid-producing lactic acid bacterium was screened out from the series of lactic acid bacteria in our laboratory by paper chromatography. Through microscopic examination and 16SrDNA identification, it was confirmed that the homology with the 16SrDNA of various Lactobacillus brevis published in GenBank was 99%, thus confirming that the bacterial strain is Lactobacillus brevis. The bacterial strain has been preserved in China Type Culture Collection Center on December 27, 2010, address: Wuhan, China, Wuhan University, preservation number: CCTCC NO: M 2010367, taxonomic name: Lactobacillus brevis Lb85 ( Lactobacillus brevis Lb85).

[0020] Primers were designed based on the glutamic acid decarboxylase gene LVIS_1847 of Lactobacillus brevis ATCC 367, which has been published in the full genome sequence, and the genome of the screened GABA-producing Lactobacillus brevis was used a...

Embodiment 2

[0025] Example 2: Construction of recombinant Corynebacterium glutamicum pDXW8-gadB1 / ATCC13032:

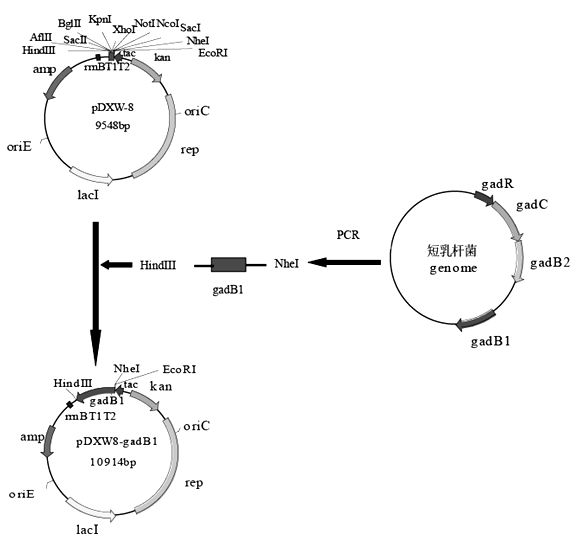

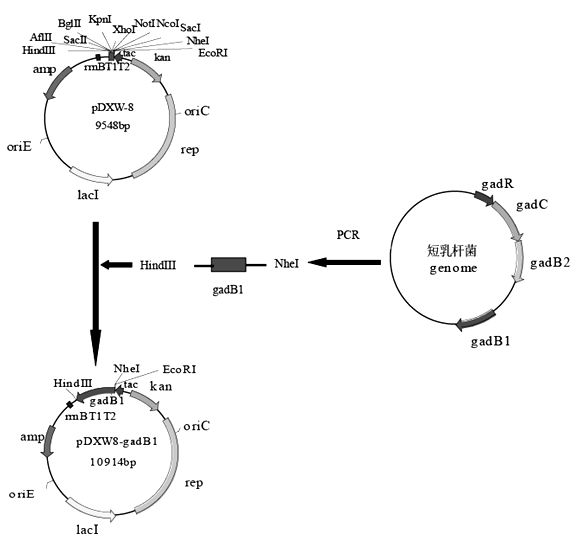

[0026] ① Digest gadB1 and pDXW-8 with the same two restriction endonucleases NheI and HindIII to recover 1.43kb and 9.48kb fragments respectively, and then connect the two fragments with T4 DNA ligase, and Transformed into Escherichia coli JM109 to complete the construction of the pDXW8-gadB1 recombinant plasmid ( figure 1 );

[0027] ② The recombinant plasmid pDXW8-gadB1 was introduced into Corynebacterium glutamicum ATCC13032 by electroporation to obtain recombinant Corynebacterium glutamicum pDXW8-gadB1 / ATCC13032.

[0028] Competent preparation of Corynebacterium glutamicum ATCC13032. Cultivate a single colony of Corynebacterium glutamicum ATCC13032 in liquid LBG medium (10g / L peptone, 5g / L yeast powder, 10g / L NaCl, 5g / L glucose) at 30°C overnight, and then transfer to Inoculated in 30mL competent medium (10g / L peptone, 5g / L yeast powder, 10g / L NaCl, 25g / L glycine, 0.1% Twe...

Embodiment 3

[0029] Embodiment three: recombinant Corynebacterium glutamicum fermentation produces GABA

[0030] Medium: seed medium (glucose 2.5%, urea 0.6%, corn steep liquor 3.0%, K 2 HPO 4 ·3H 2 O 0.15%, MgSO 4 ·7H 2 O 0.05%, pH 7.0~7.5); fermentation medium (glucose 16%, urea 0.4%, corn steep liquor 0.3%, K 2 HPO 4 ·3H 2 O 0.2%, MgSO 4 ·7H 2 O 0.08%, MnSO 4 2mg / L, FeSO 4 2mg / L, pH 7.0~7.5)

[0031] Culture conditions: After the recombinant Corynebacterium glutamicum was shaken in the seed medium for 12 hours at 30°C, it was transferred to the fermentation medium with a 10% inoculum size for fermentation, and 1 mM IPTG was added for induction at 12 hours of fermentation, and in the subsequent Within 24 hours, the pH value of the culture medium was controlled in a neutral range by intermittently adding urea, and then the fermentation was continued until 60 hours, and the content of γ-aminobutyric acid in the fermentation broth was determined.

[0032] The content of gamma-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com