Method for preparing sintering ore of vanadium-titanium magnetite ore

A technology of vanadium-titanium magnetite and vanadium-titanium magnetite concentrate, which is applied in the field of vanadium smelting, can solve the problems of poor strength index of pure vanadium-titanium magnetite sinter, poor sinter particle size composition, restriction of blast furnace smelting strength, etc., and achieve improvement The effect of improving the quality of sinter, small burning loss, and improving the balling performance of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 vanadium-titanium magnetite pellets

[0025] The preparation of vanadium-titanium magnetite pellets adopts the method of disc pelletizing and cylinder rolling to prepare double alkalinity pellets. material.

[0026] Test raw material

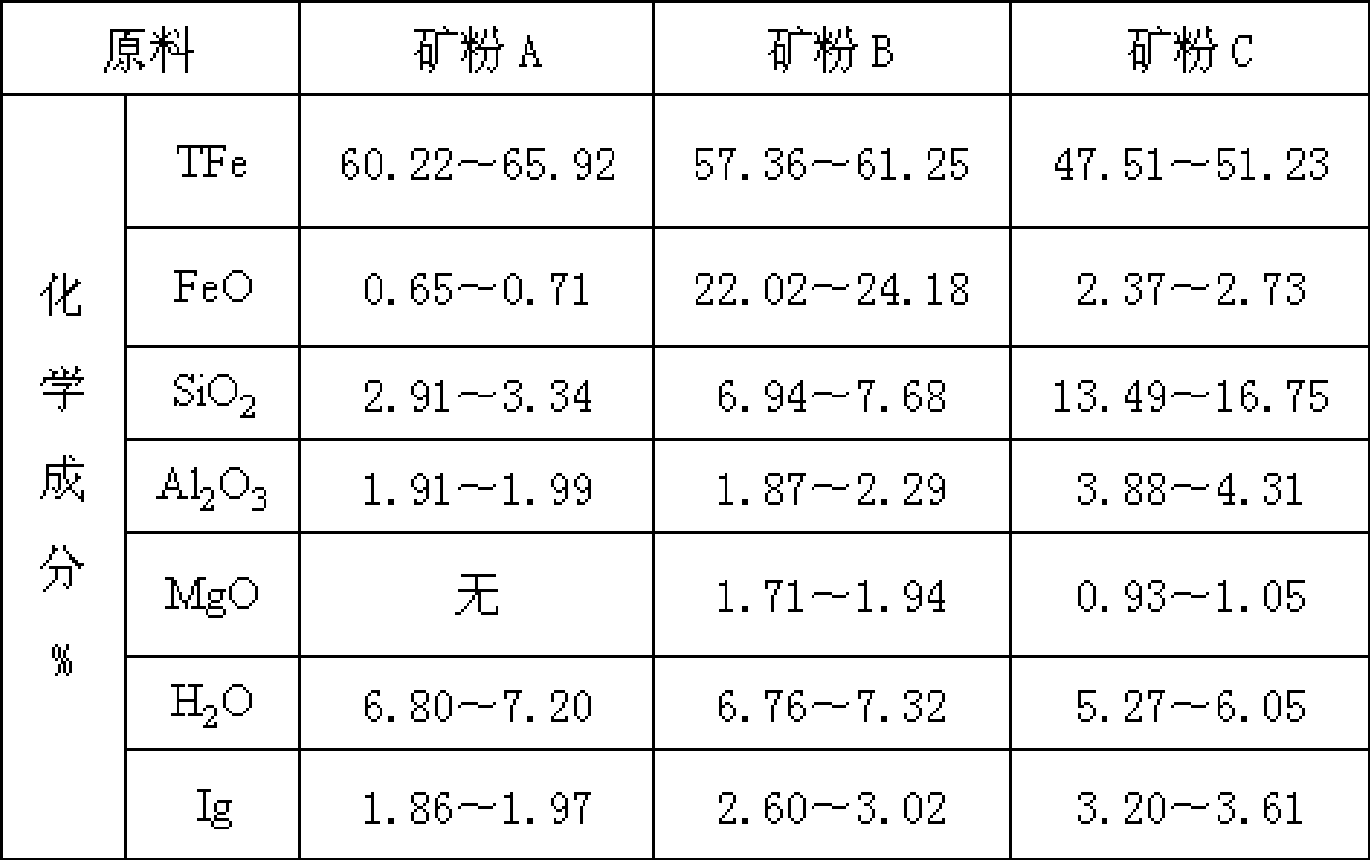

[0027] The main components of each raw material adopted in the embodiment are shown in Table 2:

[0028] Table 2 Unit: weight percentage (%)

[0029] Element Vanadium Titanium Magnetite Concentrate Mineral powder C Mineral powder A Mineral powder B limestone quicklime Scorched powder TF 54.30 50.50 63.21 59.40 0.56 0.35 0.50 CaO 0.90 0.00 0.00 3.13 52.73 86.10 1.15 SiO 2 3.25 13.00 3.10 7.52 1.81 1.60 9.80 moisture 11.8 5.6 7.00 7.00 2.30 0.00 8.00

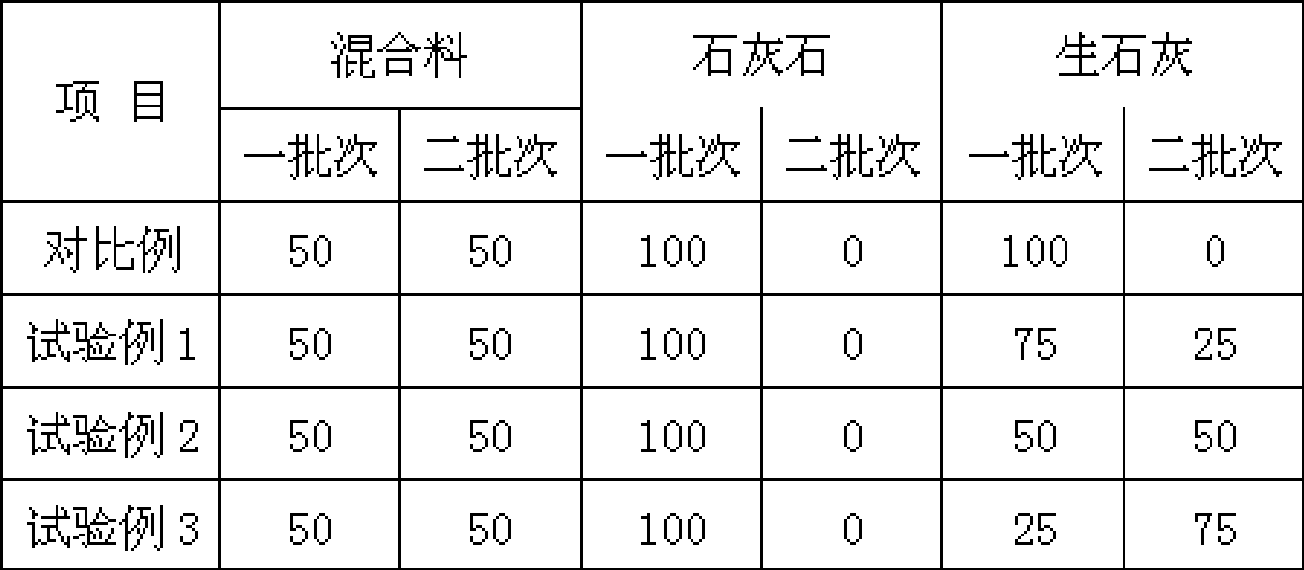

[0030] This embodiment has prepared 1 comparative example and 4 test examples, and the ratio of raw materials is all the same, as follows:

[0031] 1. 54 kg of vanadium-titanium mag...

Embodiment 2

[0040] Example 2 Preparation of sintered ore

[0041] In four sintering cups of φ250×750 mm, four kinds of pellets prepared in Example 1 were laid respectively, the particle size of the bottom material was 10-20 mm, and the thickness of the bottom material was 20 mm. The sintering conditions are: ignition time 2min, ignition negative pressure: 600mmH 2 O, sintering negative pressure: 1200mmH 2 O.

[0042] After the sinter is burnt, it is poured out, cooled naturally, dropped twice from a height of 2 meters, and sieved. The yield of +10mm particle size is calculated, and 7.5kg of 10-40mm particle size is taken for 1 / 2ISO drum, and finally used 6.3mm and 0.5mm standard sieves are screened, the +6.3mm particle size content is used to measure the drum index, and the -0.5mm particle size content is used to measure the anti-wear index.

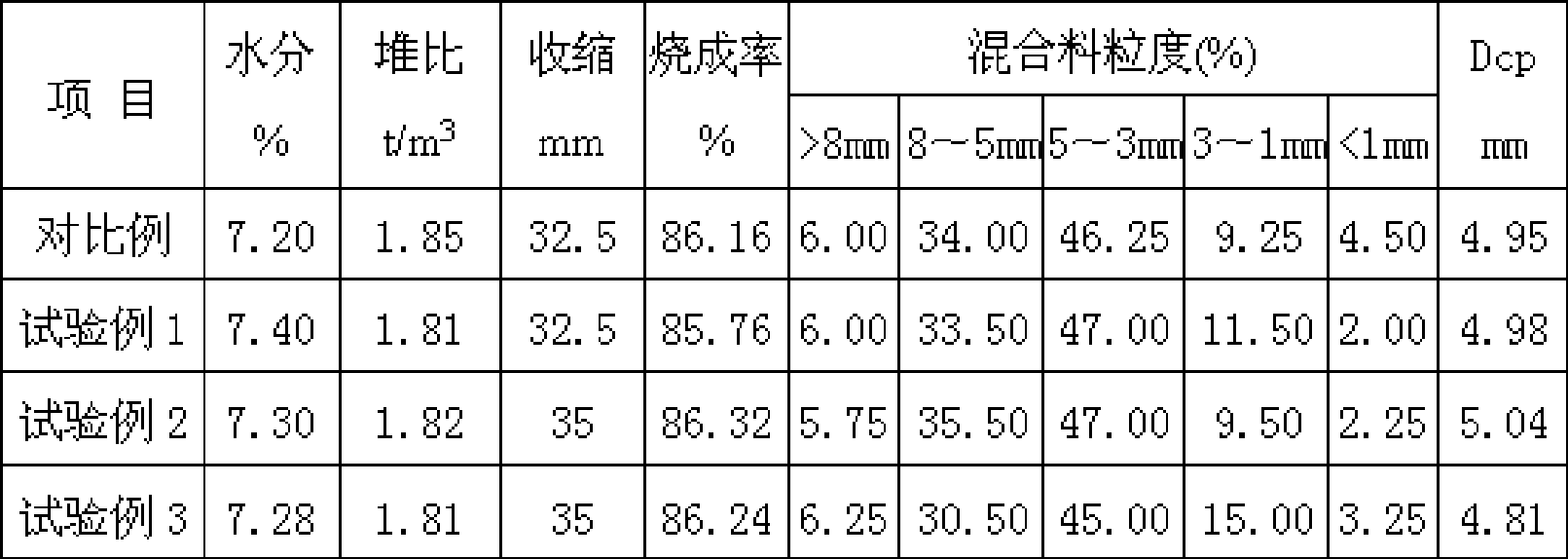

[0043] The particle size composition, bulk specific gravity, moisture and other data of the sintered ore of the comparative example and each tes...

Embodiment 3

[0058] Example 3 Sinter lithofacies results and analysis

[0059] The lithofacies composition of Test Example 2 and comparative sinter prepared in Example 1 were detected, and the main phases and content comparison of sinter are shown in Table 7:

[0060] Table 7 Unit: %

[0061] lithofacies comparative example Test example 2 Titanium hematite 30~31 32~35 Titanium Magnetite 23~27 20~22 ferrite phase 27~30 30~32 perovskite 1.3~1.6 0.8~1.0 Titanium Garnet not seen not seen pyrrhotite not seen not seen Free CaO 0.4~0.7 0.4~0.6 glass phase 1~1.5 1.5~2 Total amount of silicate phase 10.5~15 10~12.7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com