Method for producing yeast single cell protein by blue algae fermentation

A single-cell protein and cyanobacteria technology, applied in the field of cyanobacteria treatment, can solve the problems of environmental pollution, high cost of burning cyanobacteria, and difficulty in cyanobacteria disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

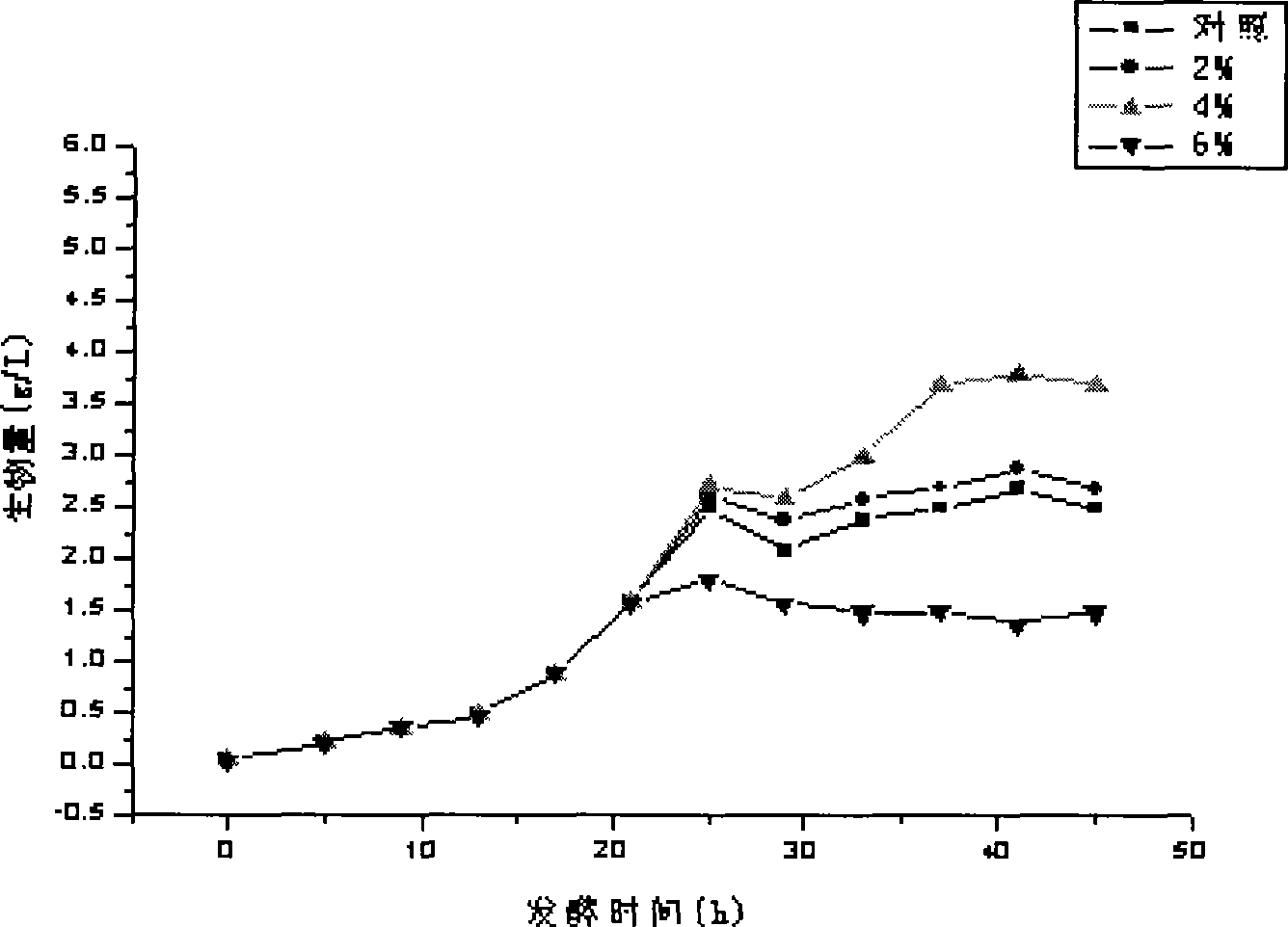

[0018] Embodiment 1: Determination of the best carbon source

[0019] The concentration of cyanobacteria salvaged from Taihu Lake is 2% (dry weight), and it is made into a culture medium after breaking the wall at high temperature. optimization. The carbon-nitrogen ratio in cyanobacteria is 5.5 / 1, and the carbon-nitrogen ratio required for yeast growth is 11.4 / 1, so 0.9% glucose can be added to 1% (dry weight) cyanobacteria medium to adjust the carbon-nitrogen ratio. The residual sugar content of 1% cyanobacteria medium was 0.26g, 0.172g after 12h fermentation, 0.075g after 16h fermentation, 0.069g after 20h fermentation, and 0.057g after 24h fermentation. Therefore, glucose can be added after 20 hours of cultivation. The amount of glucose added is 0%, 2%, 4%, and 6%. , the pH is 6, and the inoculum size is 10%. Adding 4% glucose has the highest yeast biomass, and the yeast cell mass can reach 3.8g / L when cultured for 36 hours. At this time, the residual sugar is 0.169g, an...

Embodiment 2

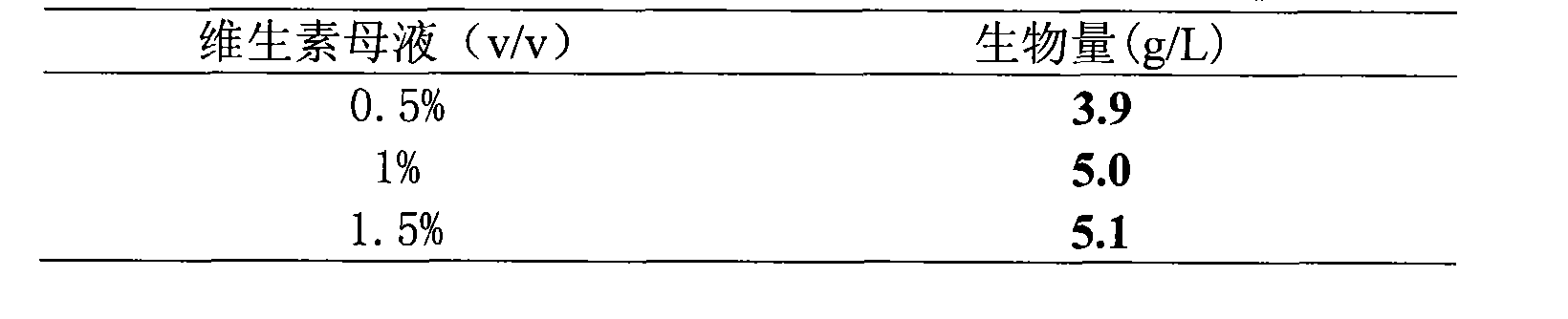

[0020] Embodiment 2: the determination of vitamins, trace elements and mineral elements in the culture medium

[0021] On the basis of carbon source optimization, vitamin mother liquor, trace element mother liquor and mineral element mother liquor were added to the medium to investigate their effects on fermentation. The results showed that the yeast yield reached the maximum after 36 hours of fermentation. The results are shown in Tables 1, 2, and 3. , it can be seen from the table that adding 1% of vitamin mother solution can significantly increase the biomass. After 36 hours of cultivation, the yeast yield reached 5g / L, but the addition of trace elements and mineral elements had no obvious effect on the yeast biomass.

[0022] Vitamin Mother Solution (g / L): Vitamin B 1 1. Nicotinic acid 0.4, pyridoxine 0.4, biotin 0.02, calcium pantothenate 2, riboflavin 0.2, inositol 1, p-aminobenzoic acid 0.2;

[0023] Table 1 Effects of different vitamin mother liquor additions on yeas...

Embodiment 3

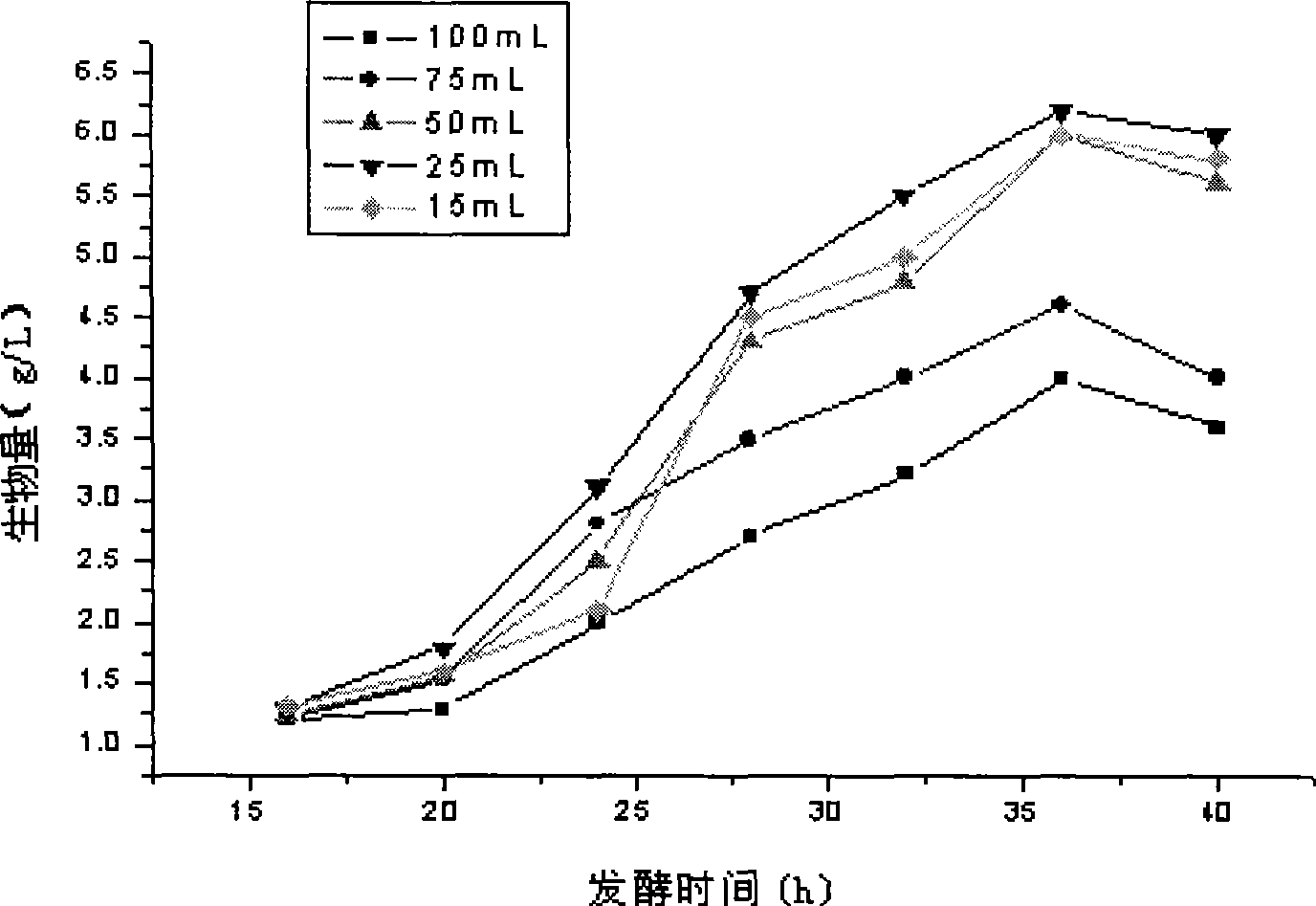

[0029] Embodiment 3: Determination of optimal culture conditions

[0030] On the basis of medium optimization, the effects of fermentation temperature, initial pH value of medium and inoculation amount on fermentation results were investigated, and the results are shown in Tables 4, 5, and 6. It can be seen from the table that the optimum temperature for fermentation is 28°C, the initial pH value of the optimum medium is 6, and the optimum inoculum size is 15%.

[0031] Table 4 Effect of temperature on yeast biomass

[0032]

[0033] Table 5 Effect of pH value on yeast biomass

[0034]

[0035] Table 6 Effects of different inoculum sizes on yeast biomass

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com