Method for modifying diatomite and immobilization of glucose isomerase containing cells

A technology of glucose isomerase and diatomite, which is applied in the direction of isomerase, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high production cost of fructose syrup, achieve high-efficiency preparation, good stability, The effect of high recovery rate of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Diatomaceous earth modification

[0035] Take an appropriate amount of natural diatomaceous earth and add it to 2 times the volume of 6M hydrochloric acid solution, react for 2 hours to remove some metal oxide impurities, wash with deionized water until neutral, and resuspend in H 2 SO 4 and HNO 3 mixed acid (H 2 SO 4 Concentration 72%, HNO3 Concentration 17%) (mixed acid dosage is 6mL / g diatomaceous earth), ultrasonic treatment at 40°C for 3h to increase the oxygen content on the surface of diatomite, cooled to room temperature, suction filtered and washed with deionized water until neutral. Add an equal volume of water to the oxidized diatomite to make a slurry, place it in a muffle furnace and roast at 500°C for 3 hours, then filter, dry, and sieve to obtain modified diatomite, which is stored dry for later use. The prepared modified diatomite has a particle size of 1.5-4nm and a specific surface area of 17.56m 2 / g, pore volume 0.092mL / g, pore d...

Embodiment 2

[0039] Example 2: Construction of recombinant Escherichia coli E.coli BL21(DE3) / pET-28b-TEGI and preparation and performance determination of wet cells

[0040] The specific method is as follows:

[0041] (1) Construction of recombinant bacteria: the GI gene TEGI (nucleotide sequence shown in SEQ ID NO.1) of Thermoanaerobacter ethanolicus was ligated with PGEM-T vector and introduced into E.coli JM109, TEGI / PGEM-T and plasmid pET28b(+)-Nit were double digested, ligated overnight with ligase, and the ligation product pET28b(+)-TEGI was introduced into host E.coli BL21(DE3) to obtain recombinant E. coli E. coli. coli BL21(DE3) / pET28b(+)-TEGI.

[0042] The sequence of SEQ ID NO.1 is as follows:

[0043] atggtagaatacttcaaaaacgttcctcaaatcaaatacgaaggccctaaatctaacaacccttacgctttcaaattctacaaccctgatgaaatcatcgatggcaaacctcttaaagaacatcttcgtttctctgttgcttactggcatacattcacagctaacggcacagatcctttcggcgctcctacaatgcaacgtccttgggatcatttcacagatcctatggatatcgctaaagctcgtgttgaagctgctttcgaacttttcgaaaaactt...

Embodiment 3

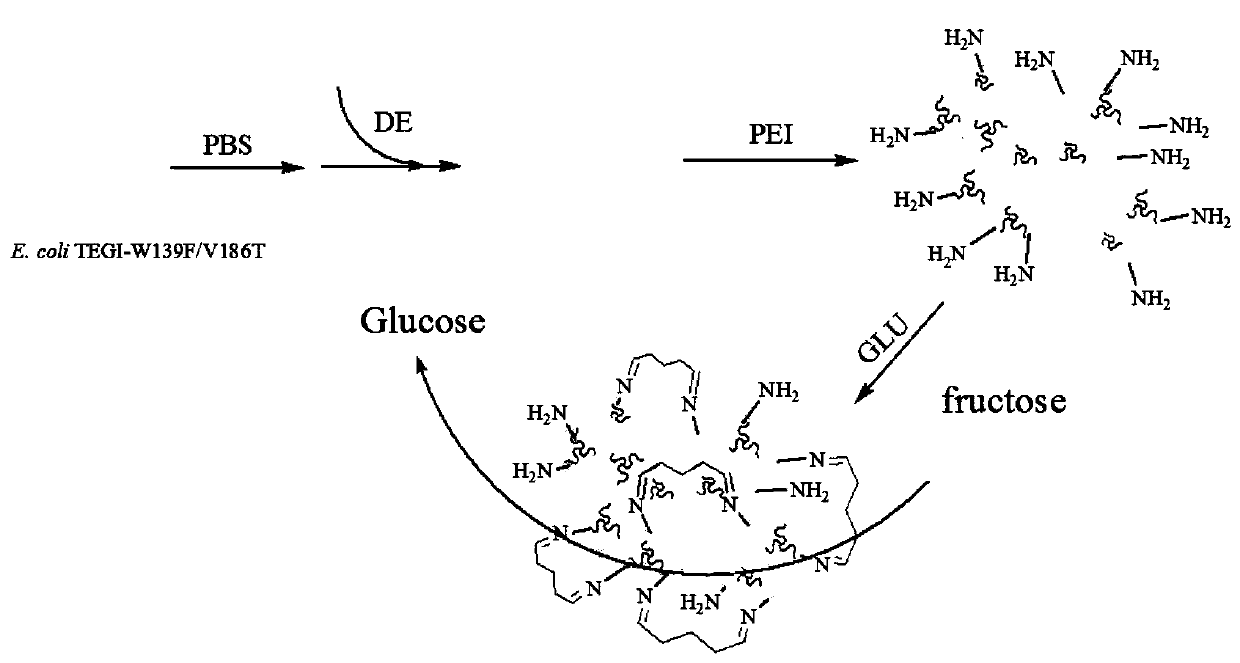

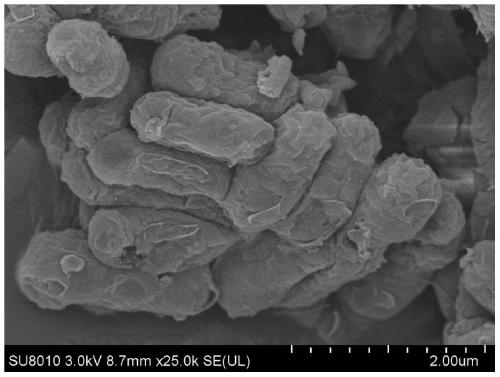

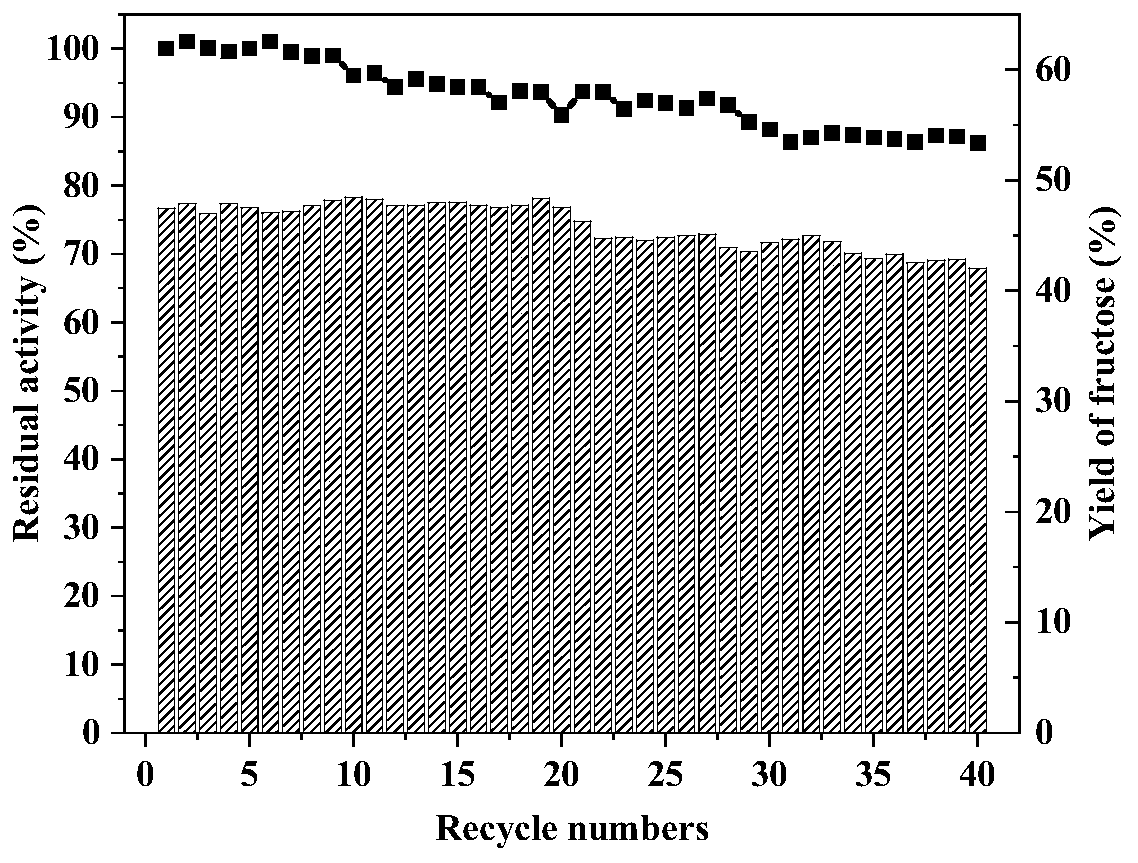

[0048] Example 3: Enzyme immobilization

[0049] Prepare Na at pH 6.5 with distilled water 2 HPO 4 / NaH 2 PO 4 Buffer (50mM), take by weighing the glucose isomerase genetically engineered bacterium wet cell that 1g embodiment 1 method prepares and join the Na of 20mL pH6.5 2 HPO 4 / NaH 2 PO 4 Buffer (50mM), stirred thoroughly to obtain 20mL bacterial suspension. Accurately weigh 0.2g of natural diatomite and modified diatomite and add them to 20mL of bacterial suspension for mixing. At room temperature (25°C) and 650rpm, stir and adsorb in a water bath for 30min; then add 1mL of 5% polyethylene Aqueous imine solution (added by 5% of the total volume of the system), at room temperature, under the condition of 650rpm, stirred and cross-linked in a water bath for 1h, then added 1mL mass concentration of 10% glutaraldehyde aqueous solution (added by 0.5% of the total volume of the system), in At room temperature, under the condition of 650rpm, stir and crosslink in a water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com