High efficiency separation purification method of ginkgolide A, B, C, J and bilobalide monomer

A technology of ginkgolide and bilobalide, which is applied in medical raw materials derived from Ginkgo biloba, organic chemistry, etc., can solve the problems of difficult product quality and quantity to meet market demand, large consumption of reagents, low product yield, etc., and achieve quality Easy to control, avoid blindness, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

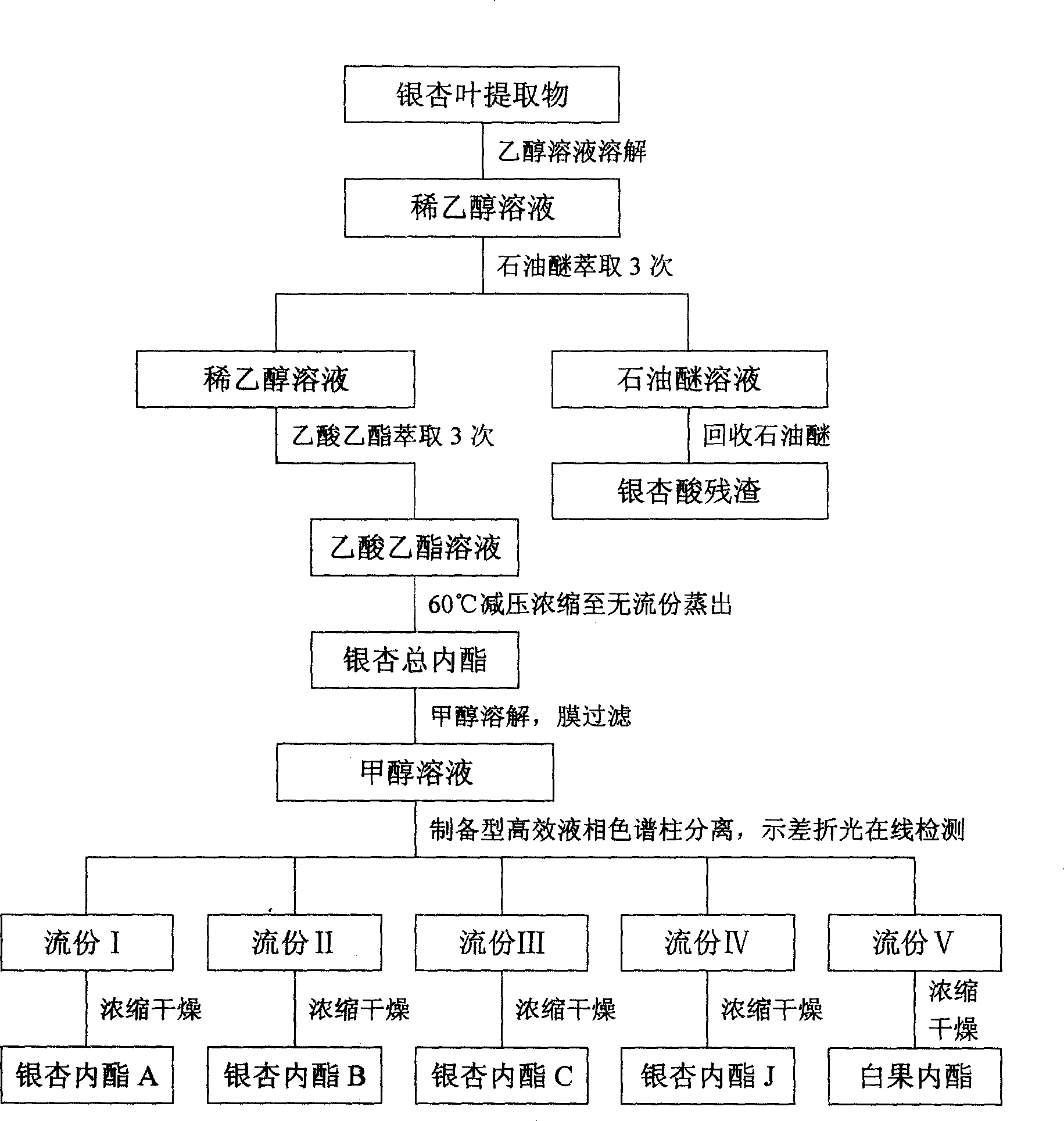

[0028] A high-efficiency separation and purification method of ginkgolides A, B, C, J and bilobalide monomer, characterized in that it is carried out according to the following process steps:

[0029] a. Ginkgo biloba extract to remove ginkgolic acid: take 1Kg of ginkgo biloba extract, add 10L ethanol solution with a concentration of 40% by volume, heat and stir at 50°C to dissolve, let stand for 2h, pour out the supernatant, and pour it into the supernatant Add 6L of petroleum ether (boiling range 60-90°C), fully shake for extraction, let stand to separate layers, and separate liquids. Do this 3 times. The petroleum ether phase recovers petroleum ether, and the residue is discarded; the water phase proceeds to step b.

[0030] b. Obtaining total ginkgo lactones: Concentrate the aqueous phase obtained in step a at 60°C under reduced pressure to recover 2L of organic reagents, add 6L of ethyl acetate to the remaining aqueous liquid, fully shake and extract, let stand to separa...

Embodiment 2

[0036] A high-efficiency separation and purification method of ginkgolides A, B, C, J and bilobalide monomer, characterized in that it is carried out according to the following process steps:

[0037] a. Ginkgo biloba extract to remove ginkgolic acid: take 500 g of ginkgo biloba extract, add 5 L of ethanol solution with a concentration of 50% by volume, heat and stir at 45°C to dissolve, let stand for 2 hours, pour out the supernatant, and pour it into the supernatant Add 3L of petroleum ether (boiling range 60-90°C), fully shake and extract, let stand to separate the layers, and separate the liquids. Do this 3 times. The petroleum ether phase recovers petroleum ether, and the residue is discarded; the water phase proceeds to step b.

[0038] b. Obtaining total ginkgo lactones: Concentrate the aqueous phase obtained in step a at 60°C under reduced pressure to recover 1.5L of organic reagents, add 2.5L of ethyl acetate to the remaining aqueous liquid, fully shake and extract, ...

Embodiment 3

[0044] A high-efficiency separation and purification method of ginkgolides A, B, C, J and bilobalide monomer, characterized in that it is carried out according to the following process steps:

[0045] a. Ginkgo biloba extract to remove ginkgolic acid: take 1500 g of ginkgo biloba extract, add 14 L of ethanol solution with a concentration of 45% by volume, heat and stir at 45 ° C to dissolve, let stand for 2 hours, pour out the supernatant, and pour it into the supernatant Add 8L of petroleum ether (boiling range 60-90°C), fully shake for extraction, let stand to separate the layers, and separate the liquids. Do this 3 times. The petroleum ether phase recovers petroleum ether, and the residue is discarded; the water phase proceeds to step b.

[0046] b. Obtaining total ginkgo lactones: Concentrate the aqueous phase obtained in step A at 60°C under reduced pressure to recover 3L of organic reagents, add 8L of ethyl acetate to the remaining aqueous liquid, fully shake and extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com