Rotating micro-example auto-introducing device

An introduction device, rotary technology, applied in the field of microfluidic analysis, to achieve the effect of low consumption, reliable performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

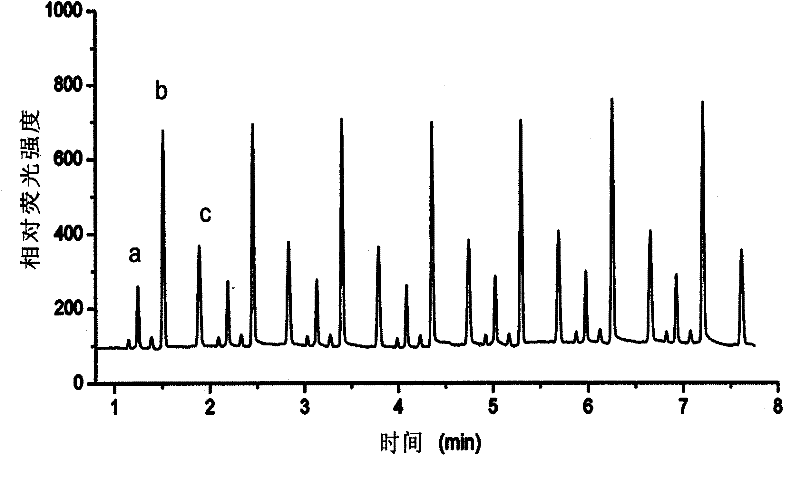

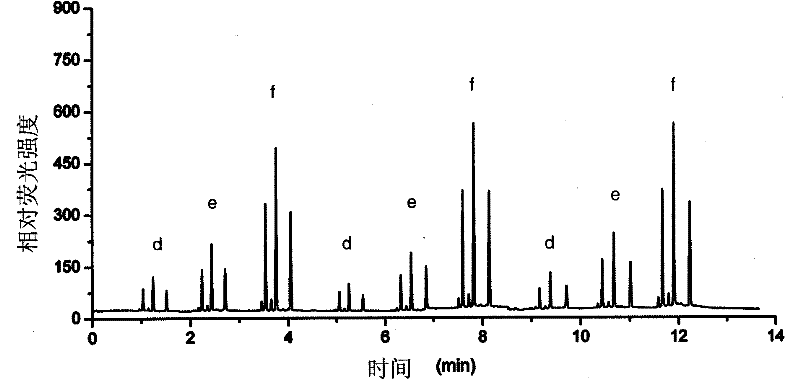

Examples

Embodiment 1

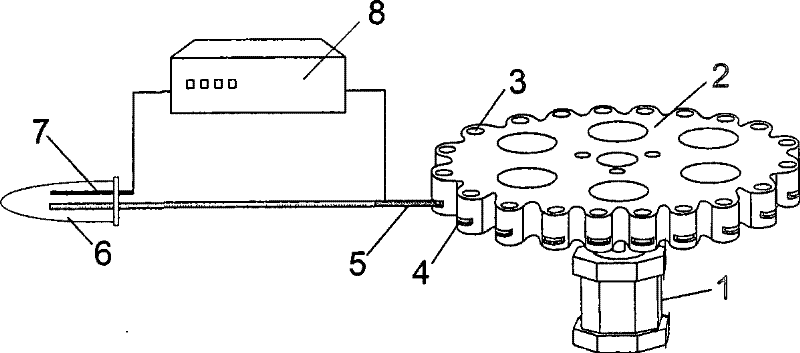

[0023] Rotary micro-sample automatic introduction device such as figure 1 As shown, the integrated sample tray 2 is gear-shaped, with a diameter of 7 cm and a thickness of 8 cm. There are 20 barrel-shaped liquid storage pools 3 evenly distributed on the edge. The inner diameter of each liquid storage pool 3 is 3.5 mm, and the depth is 7 mm. On the same horizontal plane, and each liquid storage pool 3 is evenly distributed on the integrated sample plate 2, the minimum distance between the side of the plate body and the inner wall of the liquid storage pool is 2 mm, and each liquid storage pool 3 has a same shape and the same cross-sectional area at the bottom of the outer side The pores 4 are 1.2mm in width and 2.0mm in depth. Each pore 4 connects the inside of the liquid storage tank with the outside of the integrated sample tray 2 and is on the same horizontal plane; the integrated sample tray 2 is fixed on the stepping motor 1 axis, concentric with the axis of stepper motor ...

Embodiment 2

[0032] The integrated sample tray 2 of the rotary micro-sample automatic introduction device is gear-shaped, with a diameter of 1cm and a thickness of 0.1cm. There are barrel-shaped liquid storage pools evenly distributed on the edge. The inner diameter of each liquid storage pool is 0.5mm and the depth is 2mm. , the bottom surface is on the same level, and the reservoirs are evenly distributed on the integrated sample tray, the minimum distance between the side of the tray and the inner wall of the reservoir is 2mm, and the outer bottom of each reservoir has the same shape and the same cross-sectional area pore, the pore width is 0.5mm, and the depth is 2.0mm. Each pore connects the inside of the liquid storage tank with the outside of the integrated sample plate, and is on the same horizontal plane; the integrated sample plate is fixed on the shaft of the stepping motor, and The shafts of the stepper motors are concentric.

[0033] The capillary sampling probe is a fused sil...

Embodiment 3

[0036] The integrated sample tray 2 of the rotary micro-sample automatic introduction device is gear-shaped, with a diameter of 100 cm and a thickness of 10 cm. There are 500 barrel-shaped liquid storage pools evenly distributed on the edge. The inner diameter of each liquid storage pool is 5 mm and the depth is 50 mm. The bottom surface is on the same level, and the reservoirs are evenly distributed on the integrated sample tray. The minimum distance between the side of the tray and the inner wall of the reservoir is 5mm. There is a hole with the same shape and the same cross-sectional area at the bottom of each reservoir. Pore, the width of the pore is 0.5mm, and the depth is 5mm. Each pore connects the inside of the liquid storage tank with the outside of the integrated sample plate, and is on the same horizontal plane; the integrated sample plate is fixed on the shaft of the stepping motor, and the The shaft of the motor is concentric.

[0037] The capillary sampling probe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com