Semiconductor device and method of manufacturing the same

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as the increase of current path resistance, and achieve the effect of avoiding resistance increase and easy depth control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

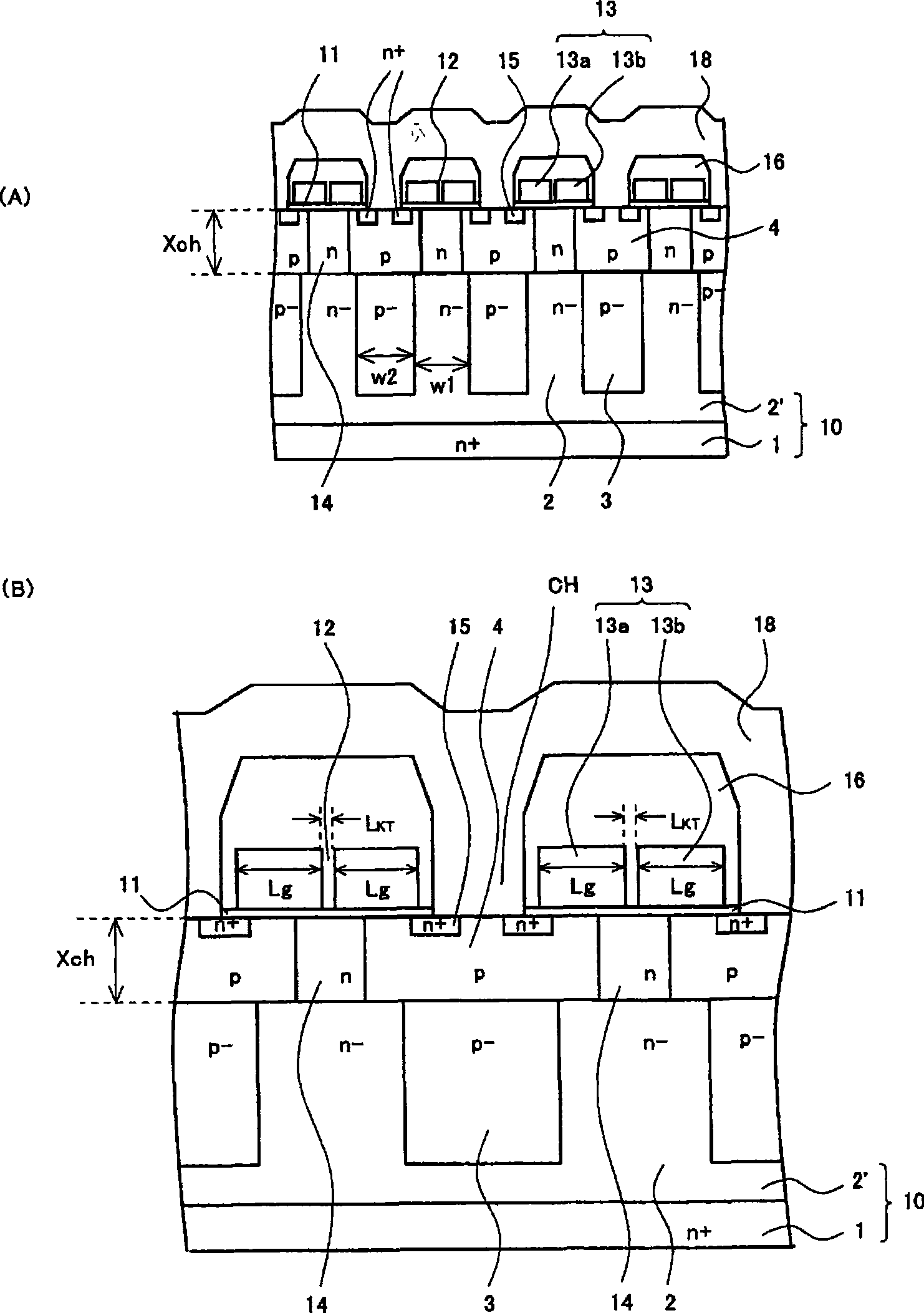

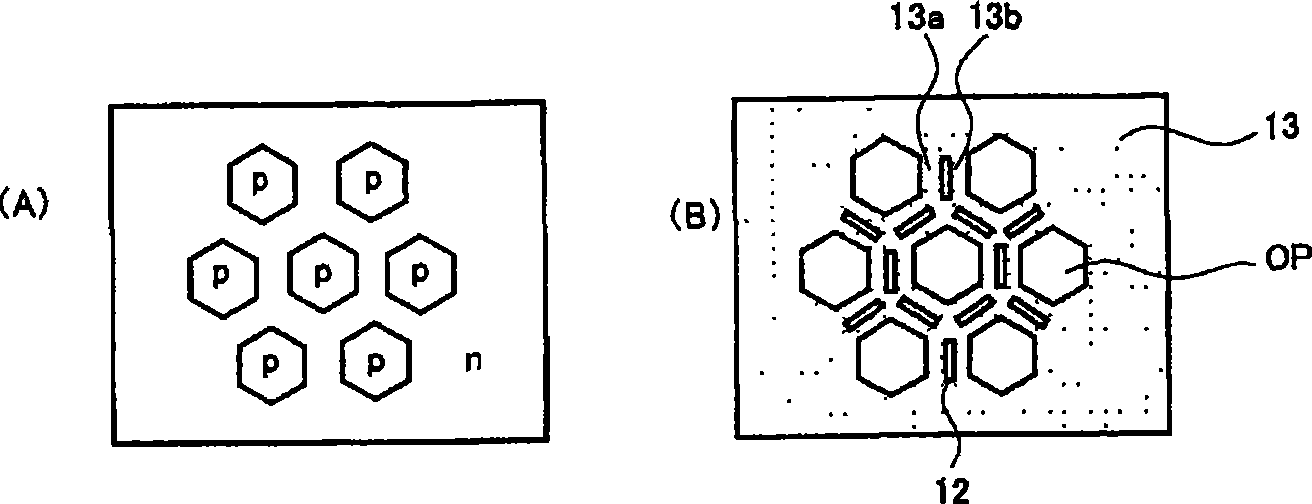

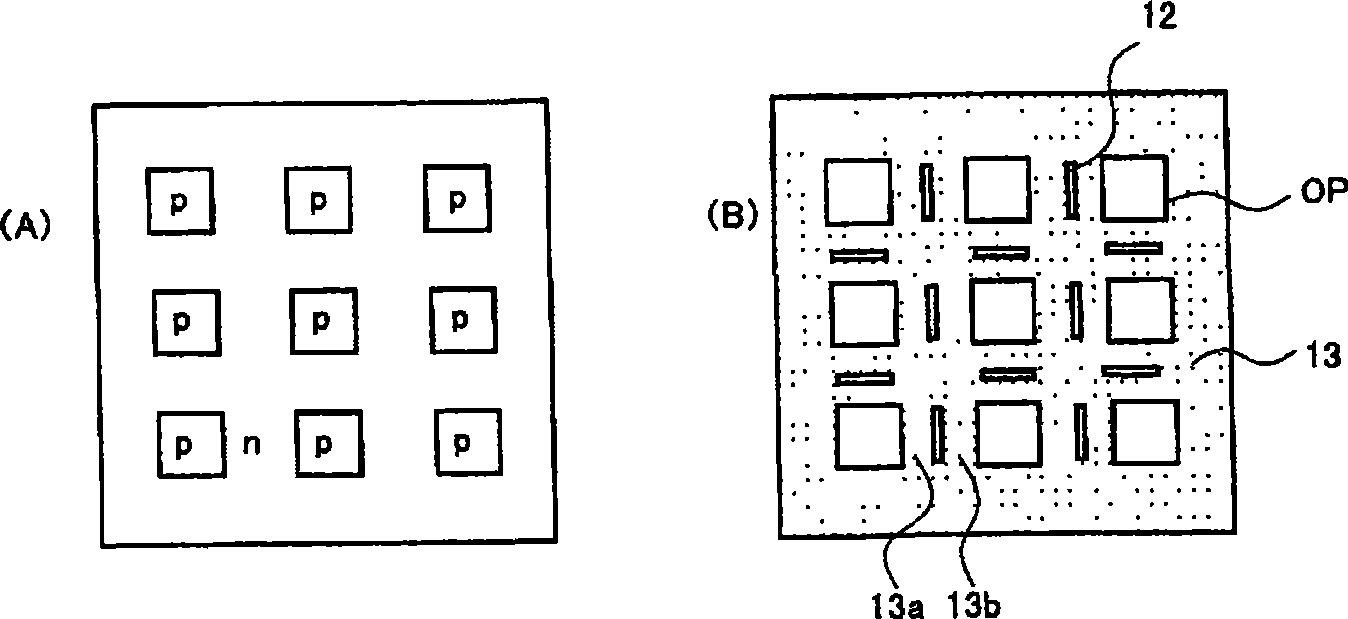

[0055] Refer below Figure 1 to Figure 12 , the embodiment of the present invention will be described by taking an n-channel MOSFET as an example.

[0056] figure 1 It is a sectional view showing the structure of the MOSFET of this embodiment. figure 1 (A) is a sectional view showing a plurality of MOSFET cells, figure 1 (B) is figure 1 (A) Partial enlarged cross-sectional view.

[0057] The MOSFET has: a semiconductor substrate 1, a semiconductor region 2 of a conductivity type, a semiconductor region 3 of a reverse conductivity type, a channel region 4, an impurity region 14 of a conductivity type, a gate electrode 13, a gate insulating film 11, an interlayer insulating film 16, and source region 15 .

[0058] The substrate 10 has a super junction structure, and a plurality of columnar n-type semiconductor regions 2 and p-type semiconductor regions 3 are alternately arranged on the n+ type silicon semiconductor substrate 1 .

[0059] Here, the so-called super junct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com