Laser scribing dust collector and operation method thereof

A technology of dust removal device and laser engraving, which is used in fine work devices, work accessories, stone processing equipment, etc., can solve the problems of low dust removal efficiency, aging wiring, noise pollution, etc., and achieve high dust removal efficiency, accelerated aging, and consumption. Can less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

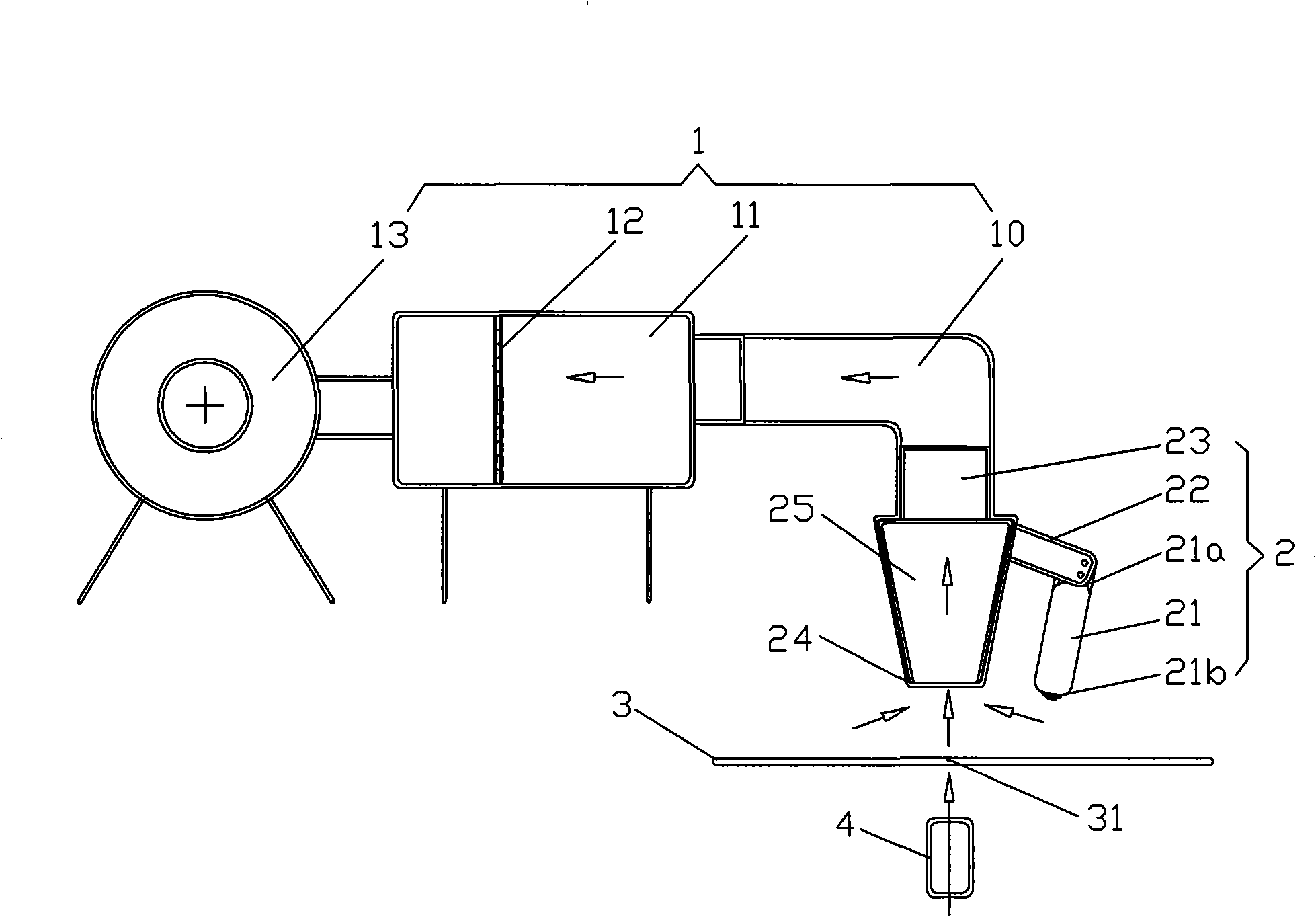

[0019] Such as figure 1 As shown, the laser engraved dedusting device of the present invention is applied to dedusting when the laser generator 4 is scribed to the amorphous silicon solar panel 3. The device 1 communicates with the exhaust device 2, and the exhaust device 2 includes an exhaust box 25 and a static elimination bar 21 connected to the outside thereof, and the exhaust box 2 has an air inlet 24 of the exhaust box and an air outlet 23 of the exhaust box. The air outlet 23 of the exhaust box is in communication with the dust collection device 1, and the air inlet 24 of the exhaust box is covered directly above the reticle track 31 of the amorphous silicon solar panel 3; the air inlet 24 of the exhaust box covers and is The dust can be effectively absorbed above the track of the marking line, and the exhaust system provided by the low-power dust removal device can effectively absorb the dust, reducing energy consumption and noise.

[0020] Preferably, the upper end 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com