Absorption type refrigerator employing film distillation technology

An absorption refrigeration and membrane distillation technology, which is applied in the direction of refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems that cannot be adjusted artificially, the temperature drops, and the temperature should not be too low, so as to reduce the consumption of cooling water, The effect of reducing the temperature of the heat source and expanding the range of deflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

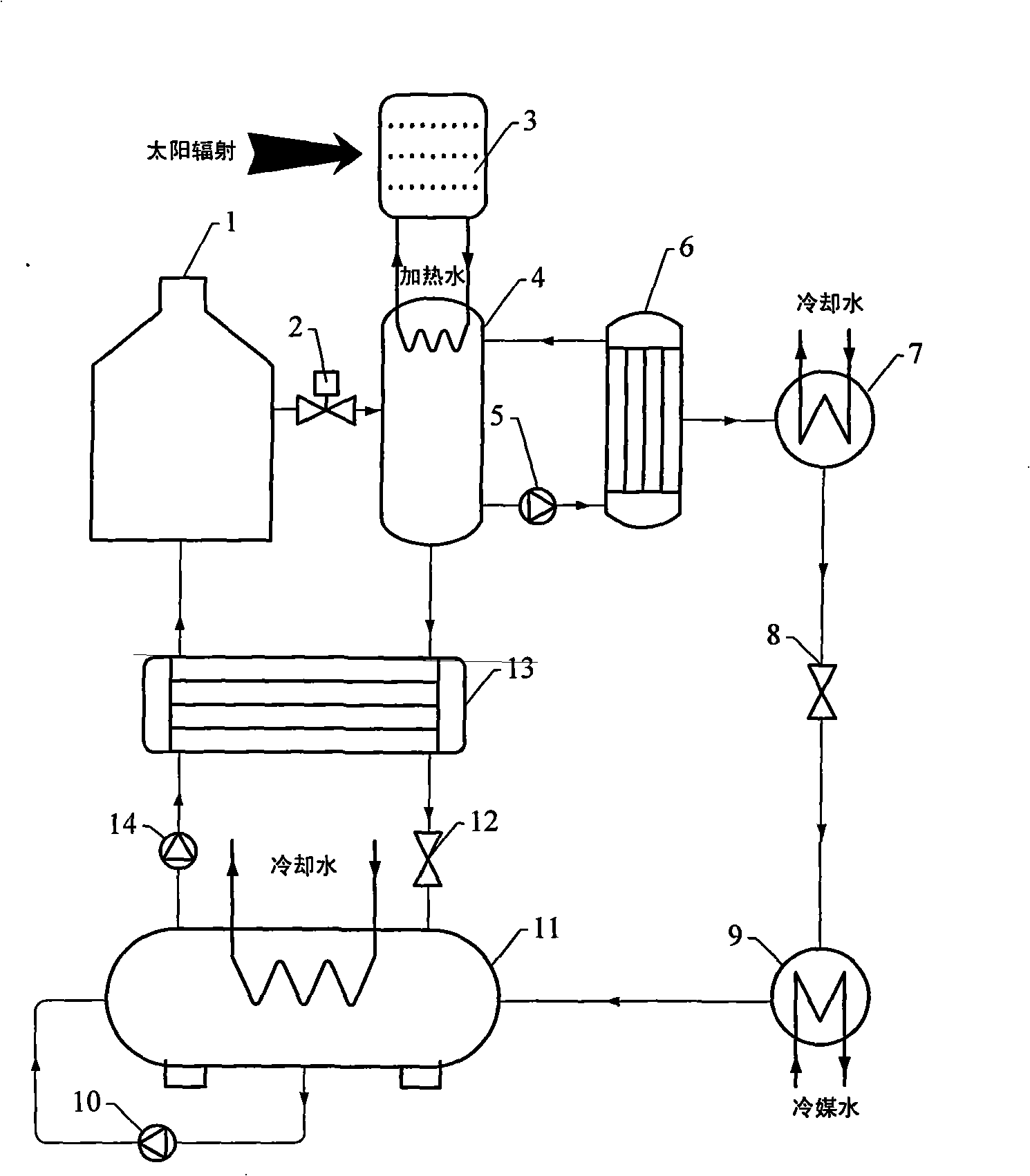

[0037] see figure 1 It is an absorption refrigeration device using membrane distillation technology, the liquid outlet of the lean liquid reservoir 1 is connected to the liquid inlet of the solution heater 4 through a pipeline, and a solenoid valve 2 is also installed on the pipeline between them . The solution heater 4 is connected to a heat collector 3 through a water pipe to form a circulation loop, and the heat collector 3 is a solar vacuum tube heat collector. The solution heater 4 is connected to the tube side of the membrane distillation generator 6 through a pipeline and a circulation pump 5 to form a circulation loop, and the vertical shell side outlet 21 of the membrane distillation generator 6 is connected in series with a condenser 7, A throttling valve 8 and an evaporator 9, the steam outlet of the evaporator 9 is connected to the steam inlet of the absorber 11, and the liquid inlet of the absorber 11 is connected to the membrane distillation solution heat exchan...

Embodiment 2

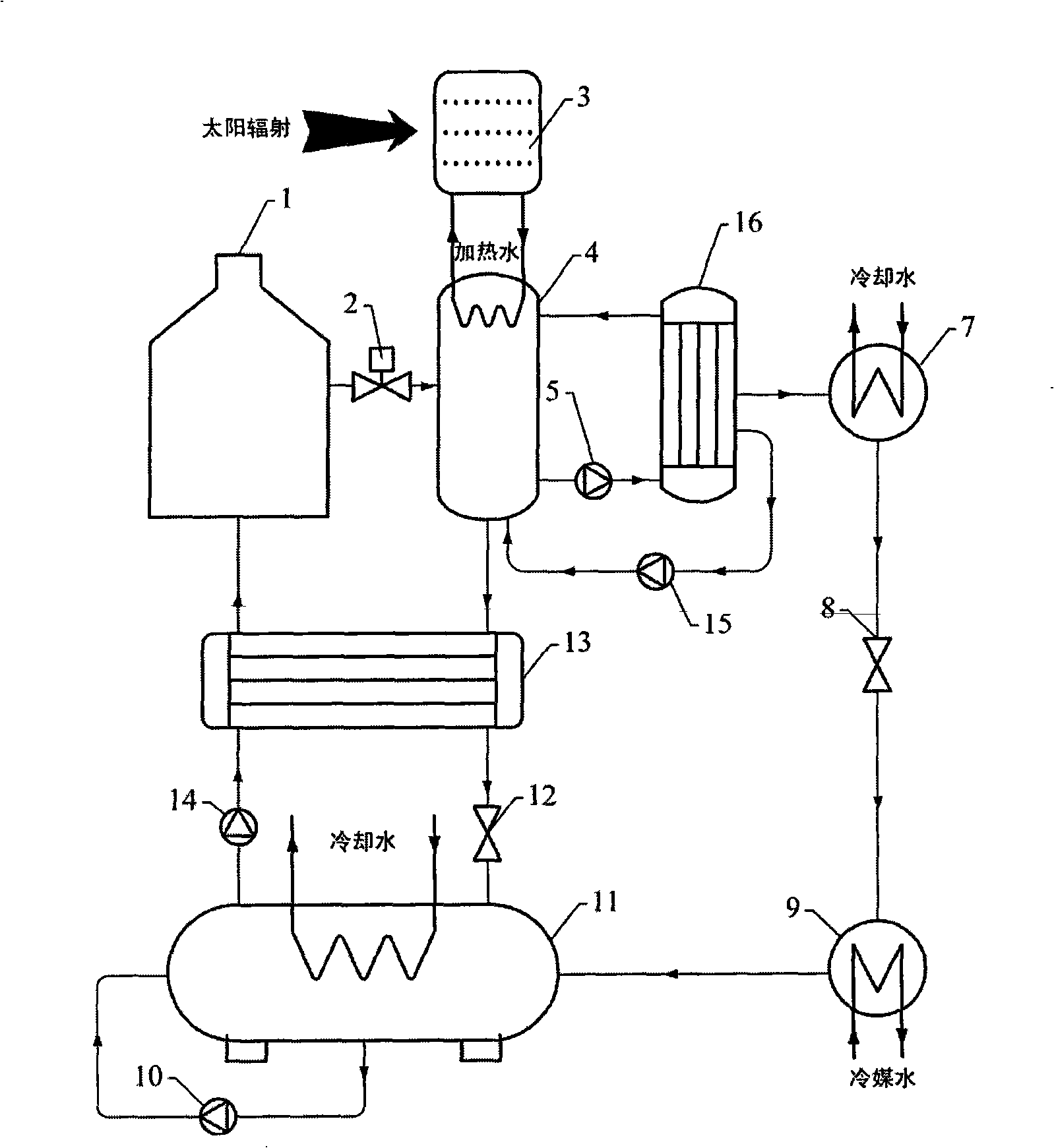

[0043] see figure 2 It is an absorption refrigeration device with membrane distillation technology that can recover permeate, and most of the connection methods of each equipment are the same as in Example 1. The difference from Example 1 is: the membrane distillation generator that can recover permeate 16 instead of the membrane distillation generator 6 in Example 1, the shell side of the membrane distillation generator 16 that can recover the permeate is connected with a solution recovery pump 15 through a pipeline, and the outlet of the solution recovery pump 15 is connected to the solution heater 4 connect.

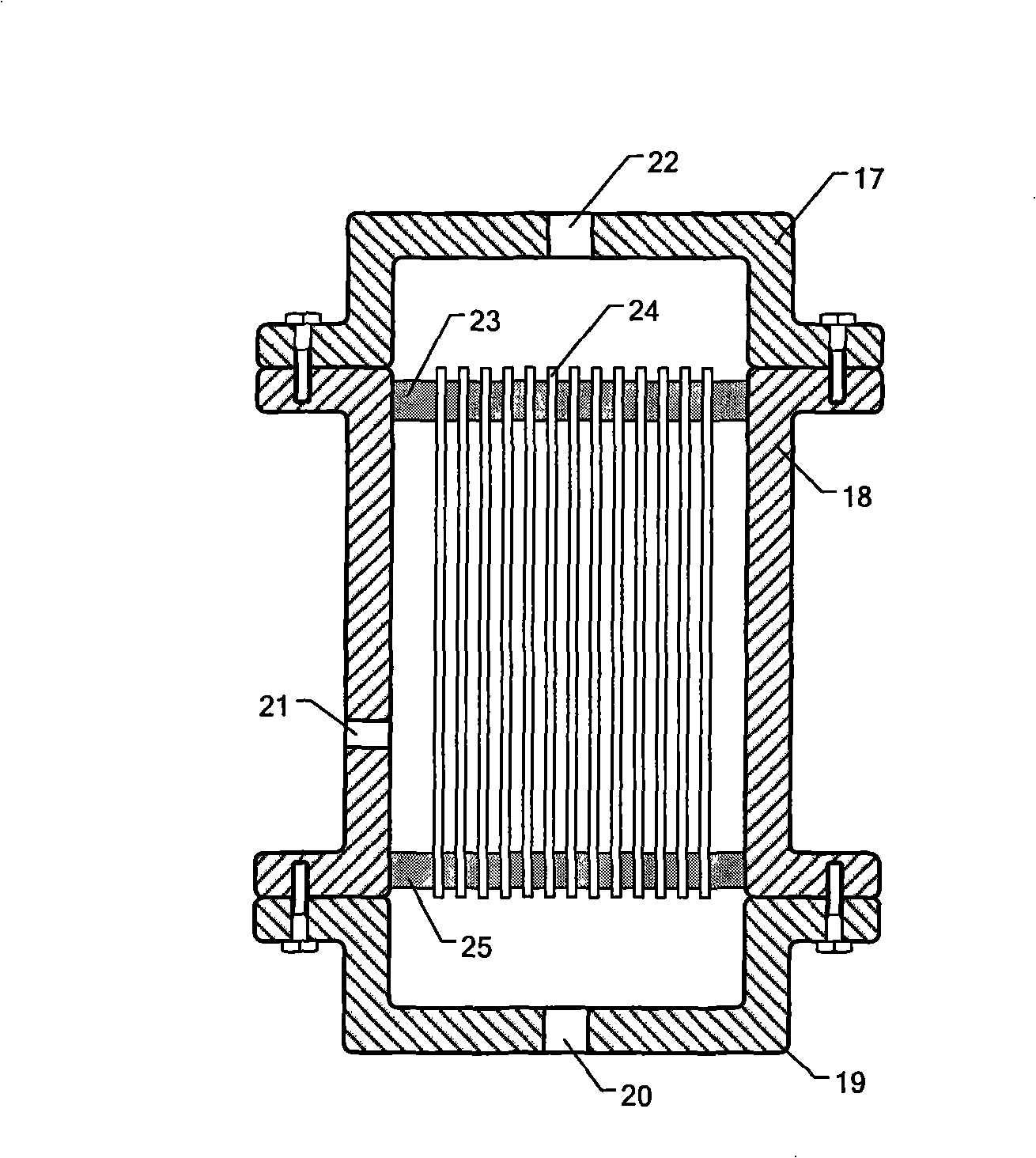

[0044] see Figure 5 It is a structural schematic diagram of a membrane distillation generator 16 that can recover permeate, and it is the same as image 3 Most of the structures of the membrane distillation generators 6 are the same, except that a permeate recovery hole 36 is provided on the vertical casing 18 for connecting with the inlet of the solution recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com