Production method for semiconductor quantum point-contained dye sensitization battery

A dye-sensitized battery and semiconductor technology, applied in the field of dye-sensitized batteries containing semiconductor quantum dots, can solve the problems of high price, complicated preparation process, and difficult source, and achieve stable working temperature range, high photoelectric conversion efficiency, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A thin layer of titanium dioxide is first sputtered on conductive glass (FTO) by magnetron sputtering, and a titanium dioxide layer with a porous structure is obtained by means of sol-gel technology on it by spin-coating (Spin-Coating). Thin layer thickness is 1-20 μm. Soaking in thioglycolic acid solution containing mercapto and carboxylic acid groups, carboxylate groups can be adsorbed on the surface of titanium dioxide. The cadmium selenide semiconductor quantum dots are prepared by high-temperature pyrolysis, and the cadmium selenide semiconductor quantum dots are dissolved in toluene after washing and centrifugal separation. The conductive glass containing the porous titanium dioxide thin layer is immersed in the quantum dot solution. Due to the function of the complex metal ion of the mercapto group, it can complex the cadmium selenide quantum dots, and then the cadmium selenide quantum dots are assembled into the pores of the porous titanium dioxide thin layer. ...

Embodiment 2

[0039] A thin layer of titanium dioxide is sputtered on conductive glass (FTO) by magnetron sputtering, and a titanium dioxide layer with a porous structure is obtained on it by means of sol-gel technology, and the thickness of the thin layer is 1-20 μm.

[0040] Prepare cadmium telluride, cadmium selenide, and zinc telluride quantum dots by high-temperature pyrolysis. After washing and particle size screening, different quantum dots with the same particle size are dissolved in toluene solution, and thioglycolic acid is added to the surface of the quantum dots. for modification and complexation.

[0041] Soak the conductive glass containing the porous titanium dioxide layer in the solution containing the zinc selenide quantum dots prepared above. Then, put them into the solution containing cadmium selenide quantum dots and cadmium telluride quantum dots in order to soak. Carboxyl groups can be adsorbed on the surface of titanium dioxide. In this way, zinc selenide, cadmium s...

Embodiment 3

[0043]A thin layer of titanium dioxide is firstly sputtered on conductive glass (FTO) by magnetron sputtering, and a titanium dioxide layer with a porous structure is obtained on it by sol-gel technology, and the thickness of the thin layer is 1-20 μm.

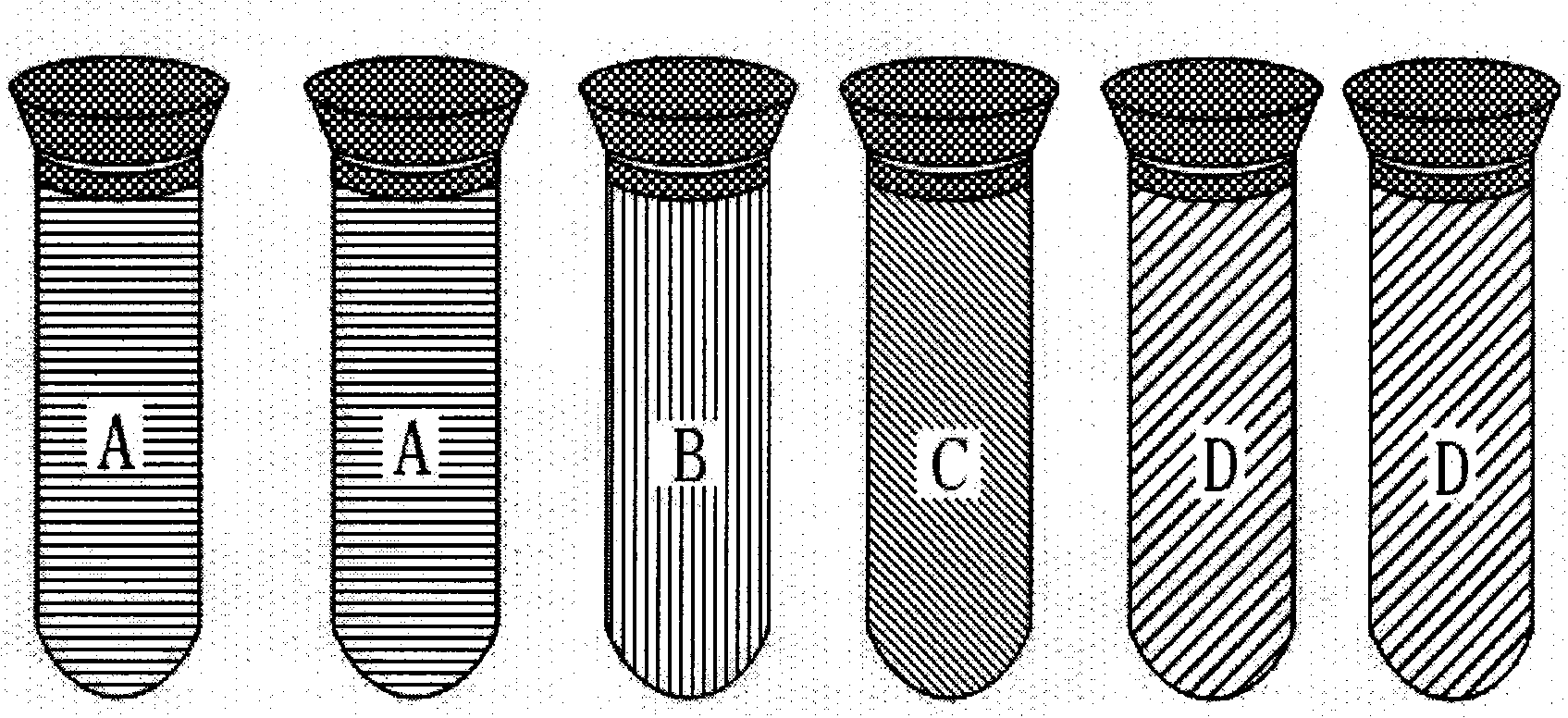

[0044] The cadmium selenide quantum dots were prepared by high temperature pyrolysis, and the products with different reaction times were taken. After washing, dissolve in toluene solution (see figure 1 ), adding thioglycolic acid to modify and complex the quantum dot surface.

[0045] Soak the conductive glass containing the porous titanium dioxide layer in the above prepared cadmium zinc selenide quantum dot solution containing blue light emitting wavelength. Next, soak them in the yellow fluorescent and red fluorescent cadmium selenide quantum solutions in sequence. Carboxyl groups can be adsorbed on the surface of titanium dioxide. In order to assemble cadmium selenide quantum dots with different particle sizes into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com