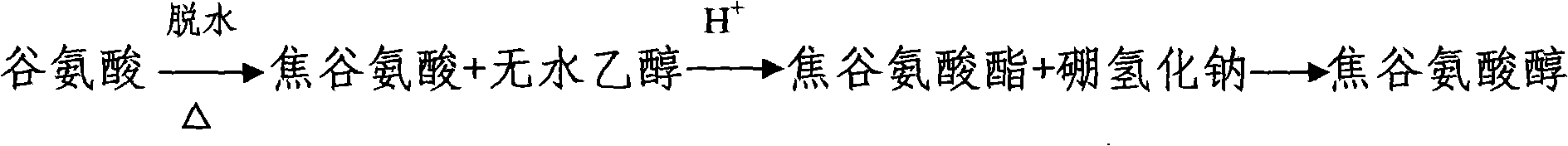

Chemical synthesis method of pyroglutamic acid alcohol and intermediates thereof

A pyroglutamic acid alcohol, chemical synthesis technology, applied in organic chemistry and other directions, can solve the problems of harsh equipment requirements, poor operating conditions, large catalyst consumption, etc., and achieves less demanding equipment requirements, easy subsequent purification, and operating conditions good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

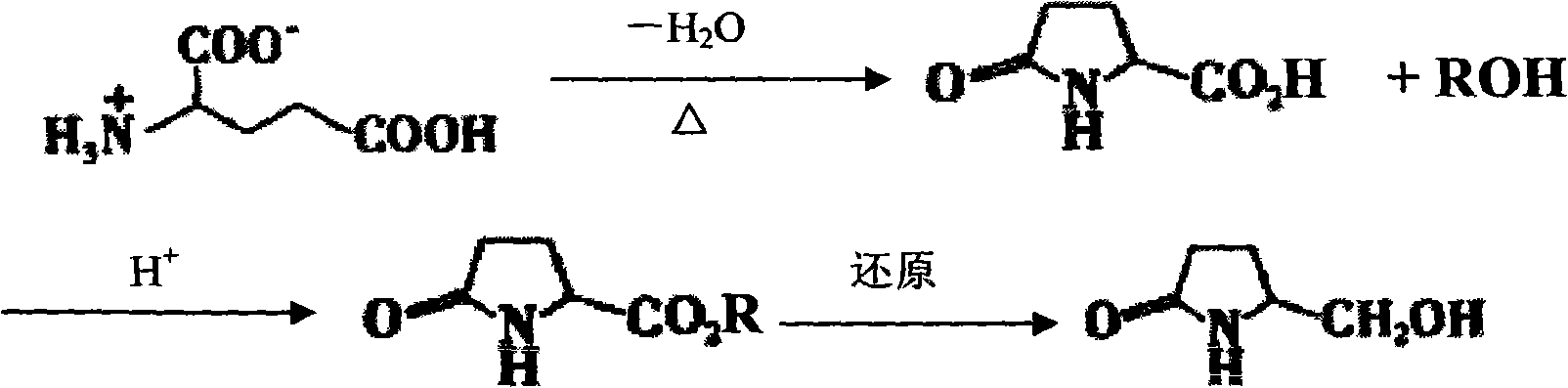

Method used

Image

Examples

Embodiment 1

[0021] Add 60kg of glutamic acid to a 200L electric heating stainless steel reaction tank, stir and dehydrate in an oil bath at 220-290°C, keep the reaction at 140°C for 55 minutes, put it into 10L of water, stir and cool, and centrifuge to obtain the crude product. The crude product is saturated with water at 65°C, centrifugally filtered, cooled to 35°C to crystallize, centrifugally washed and dried to obtain the fine product of pyroglutamic acid. The mother liquor was concentrated and refined, and a total of 28kg of fine glutamic acid was collected, with a yield of 54% (based on the theoretical yield of glutamic acid feeding), and a melting point of 159-161°C. [α] 20 =-11.6 (C=2, H 2 O).

Embodiment 2

[0023] Add 80kg of glutamic acid to a 200L electric heating stainless steel reaction tank, stir and dehydrate in an oil bath at 250-270°C, keep the reaction at 160°C for 50 minutes, put it into 10L of water, stir and cool, and centrifuge to obtain the crude product. The crude product is saturated with water at 50°C, centrifugally filtered, cooled to 30°C to crystallize, centrifugally washed and dried to obtain the refined product of pyroglutamic acid. The mother liquor was concentrated and refined, and a total of 37kg of refined pyroglutamic acid was collected, with a yield of 53.8% (based on the theoretical yield of glutamic acid feeding), and a melting point of 158.5-161°C, [α] 20 =-11.5 (C=2, H 2 O).

Embodiment 3

[0025] Add 60kg of glutamic acid to a 200L electric heating stainless steel reaction tank, stir and dehydrate in an oil bath at 220-250°C, keep the reaction at 140°C for 55 minutes, put it into 10L of water, stir and cool, and centrifuge to obtain the crude product. The crude product is saturated with water at 65°C, centrifugally filtered, cooled to 35°C to crystallize, centrifugally washed and dried to obtain the fine product of pyroglutamic acid. The mother liquor was concentrated and refined, and a total of 28kg of fine glutamic acid was collected, with a yield of 54% (based on the theoretical yield of glutamic acid feeding), and a melting point of 159-161°C. [α] 20 ==-11.5(C=2,H 2 O).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com