Titanium or titanium alloy material with modified surface as well as preparation method and use thereof

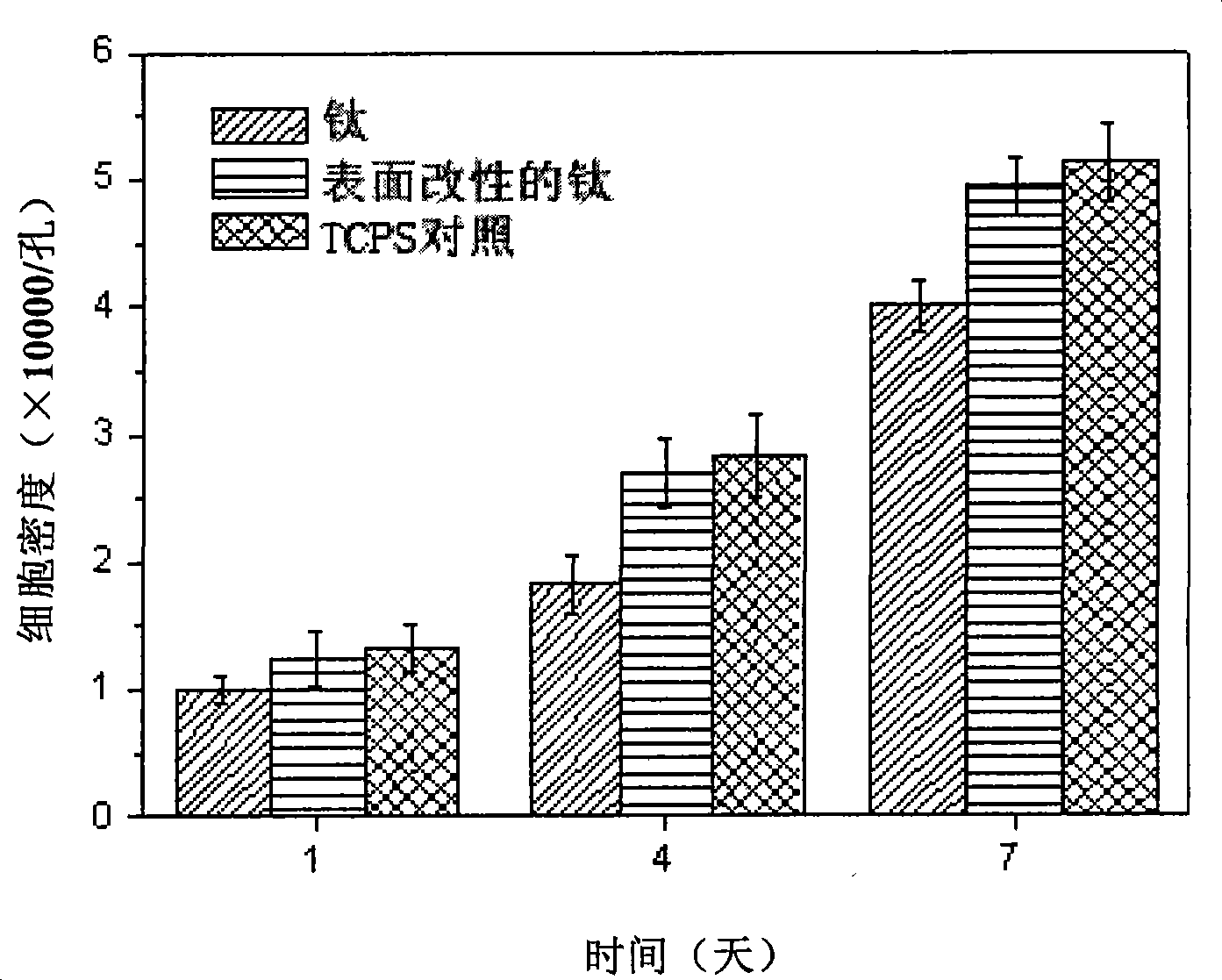

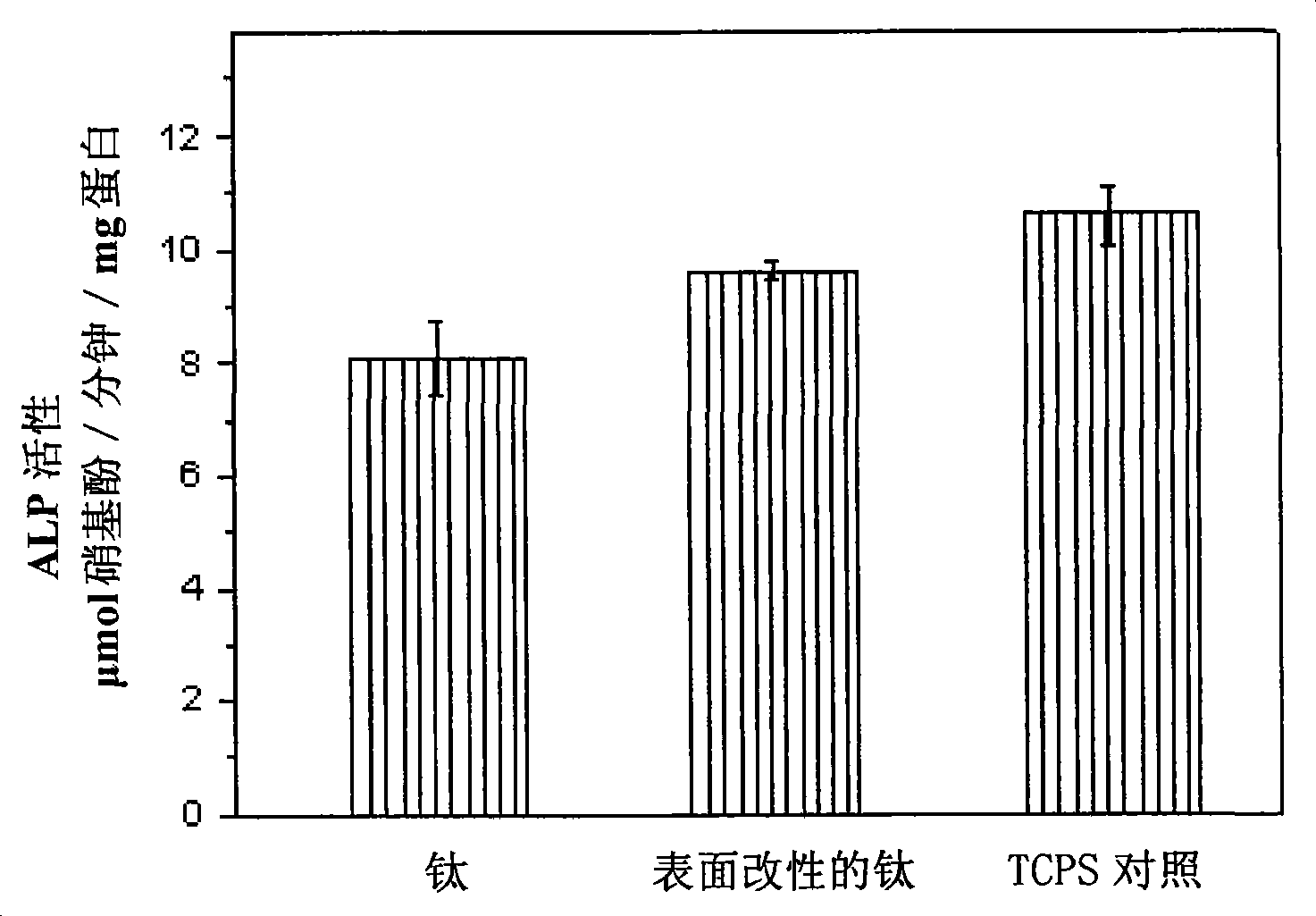

A surface modification, titanium alloy technology, applied in medical science, coating, prosthesis, etc., to achieve good osteoblast compatibility, controllable coating thickness, and promote proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is a surface-modified titanium film, and its preparation method comprises the following steps:

[0034] A, take by weighing chitosan 0.5g, adding concentration is 50mL of acetic acid solution of 10mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 1%;

[0035] b. Weigh 1.0 g of silk fibroin, add 50 mL of deionized water to dissolve it, and make a silk fibroin solution with a concentration of 2% by mass;

[0036] c. Weigh 0.025g of EDC and 0.533g of MES, add 50mL of deionized water to dissolve, and make a mixed solution containing EDC with a concentration of 0.05% by mass and MES with a concentration of 0.05mol / L;

[0037] d, the titanium film is placed in the chitosan solution prepared in step a, soaked for 10 minutes, and taken out;

[0038] e. Washing the titanium membrane processed in step d twice with deionized water, soaking for 2 minutes each time;

[0039] f. Put the titanium f...

Embodiment 2

[0044] This embodiment is a surface-modified titanium film, and its preparation method comprises the following steps:

[0045] A, take chitosan 1.0g, add concentration and be 50mL of acetic acid solution of 10mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 2%;

[0046] b. Weigh 2.5 g of silk fibroin, add 50 mL of deionized water to dissolve, and make a silk fibroin solution with a concentration of 5% by mass;

[0047] c. Weigh 0.050g of EDC and 1.066g of MES, add 50mL of deionized water to dissolve, and make a mixed solution containing EDC with a mass percentage concentration of 0.1% and MES with a concentration of 0.1mol / L;

[0048] d, the titanium film is placed in the chitosan solution prepared in step a, soaked for 20 minutes, and taken out;

[0049] e. Washing the titanium film treated in step d with deionized water 3 times, soaking for 1 minute each time;

[0050] f. Put the titanium film cleaned i...

Embodiment 3

[0055] Present embodiment is the Ti-6Al-4V titanium alloy of surface modification, and its preparation method comprises the following steps:

[0056] A, take chitosan 1.5g, add concentration and be 50mL of the acetic acid solution of 20mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 3%;

[0057] b. Weigh 4.0 g of silk fibroin, add 50 mL of deionized water to dissolve it, and make a silk fibroin solution with a concentration of 8% by mass;

[0058] c. Weigh 0.075g of EDC and 2.133g of MES, add 50mL of deionized water to dissolve, and make a mixed solution containing EDC with a concentration of 0.15% by mass and MES with a concentration of 0.2mol / L;

[0059] d, put titanium alloy in the chitosan solution that step a makes, soak for 15 minutes, take out;

[0060] e, cleaning the titanium alloy processed by step d with deionized water 3 times, soaking for 1 minute each time;

[0061] f. Put the titanium allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com